Shell-and-tube heat exchanger

A shell-and-tube heat exchanger and heat exchange tube technology, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., can solve the problems of poor thermal conductivity and poor heat exchange effect, and avoid overcooling. layer, ease of maintenance, effect of slowing down the flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

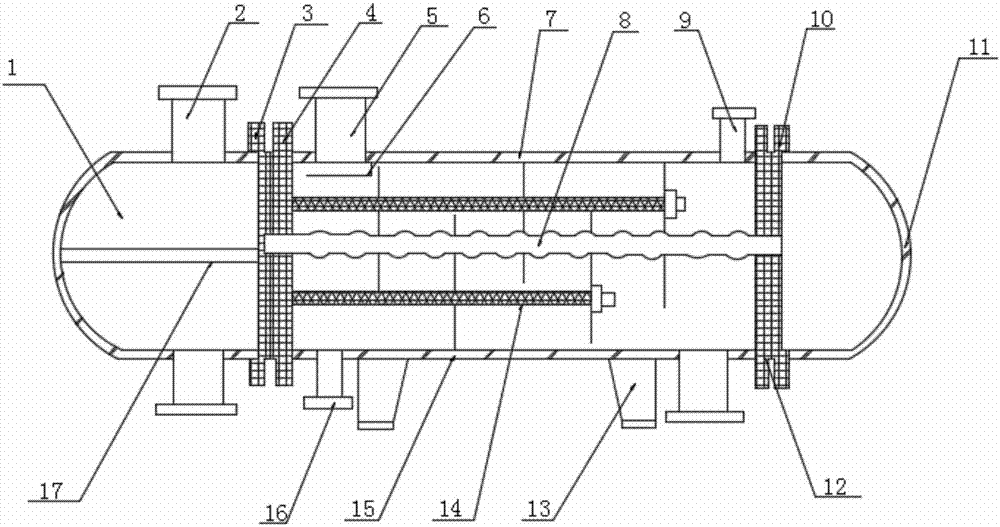

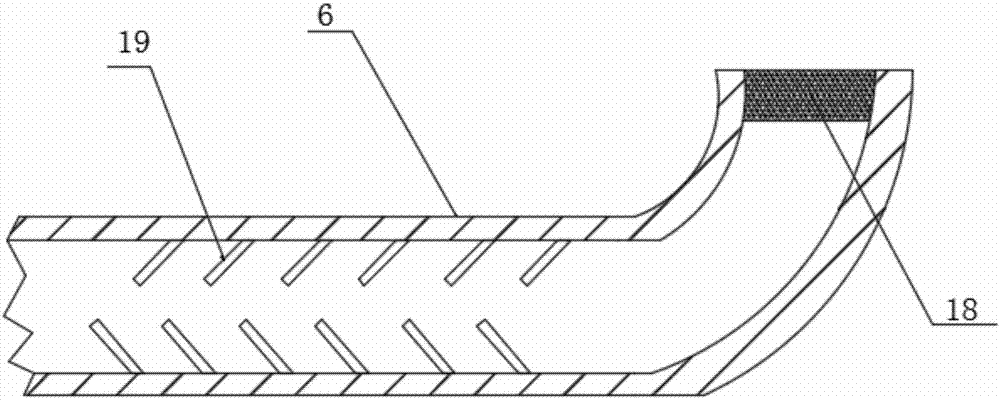

[0018] Such as Figure 1-2 As shown, the present invention provides a shell-and-tube heat exchanger, including a tube box 1 and a cylinder 7. The surface of the tube box 1 is provided with a tube-side connector 2 and a shell-side tube 5, and one side of the tube-side connector 2 The tube plate 4 is provided, the bottom of the shell-side connection tube 5 is provided with an anti-shock device 6, the inside of the cylinder 7 is provided with a corrugated heat exchange tube 8, and the surface of the cylinder 7 is provided with an exhaust port 9 and an exhaust port 9 One side is provided with a gasket 10, one side of the cylinder 7 is provided with a head 11, the bottom of the cylinder 7 is provided with a support 13, the bottom of the corrugated heat exchange tube 8 is provided with a tie rod 14, and the bottom of the tie rod 14 is provided with The baffle 15 is provided with a drainage port 16 on one side of the support 13, a partition plate 17 is provided inside the tube box 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com