Circulating fluidized bed waste incineration boiler based on grate and working method thereof

A circulating fluidized bed and waste incineration technology, applied in the combustion method, incinerator, combustion type, etc., can solve the problems of high ash proportion, high CO emission, unstable combustion, etc., to improve stability, uniform combustion, Beneficial for full combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

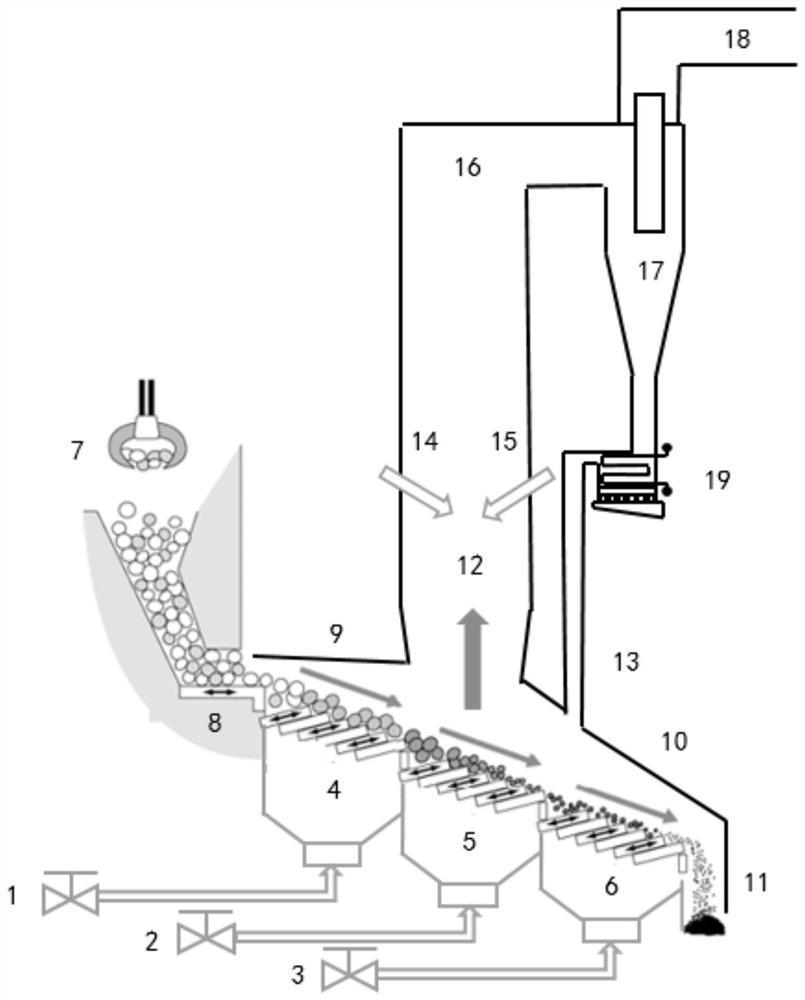

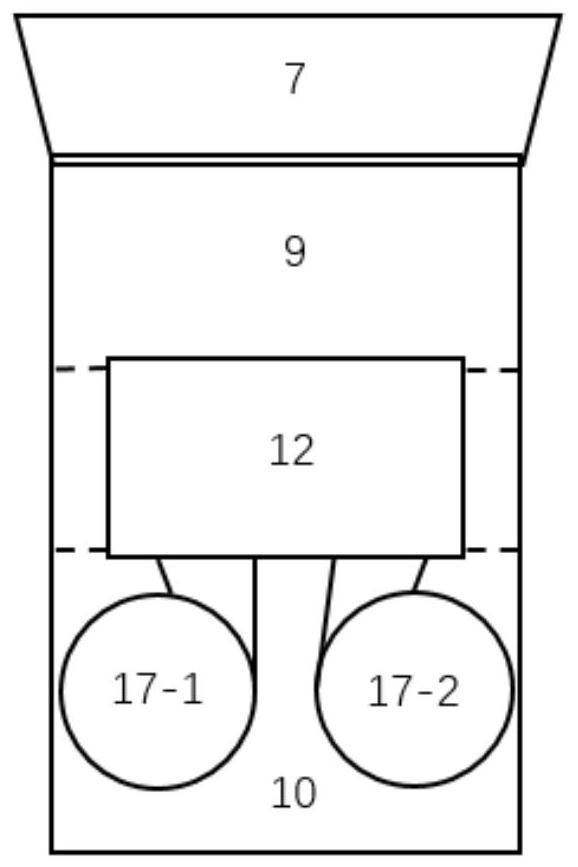

[0035] A kind of circulating fluidized bed garbage incineration boiler based on fire grate of the present invention, as figure 1 , in this embodiment, the feeding system adopts the combination of feeding grab 7 and horizontal reciprocating feeding device 8, and the feeding grab 7 is arranged above the horizontal reciprocating feeding device 8, and the horizontal reciprocating feeding device 8 It is connected with the head end of the grate drying section 4, the tail end of the fire grate drying section 4 is connected with the head end of the fluidized combustion section 5, and the tail end of the fluidized combustion section 5 is connected with the head end of the fire grate burnout section 6, The tail end of the grate burnout section 6 is connected to the slagging pipe 11, and the fluidized combustion section 5 adopts the same grate form as the grate drying section 4 and the grate burnout section 6.

[0036] The lower parts of the grate drying section 4, the fluidized combusti...

Embodiment 2

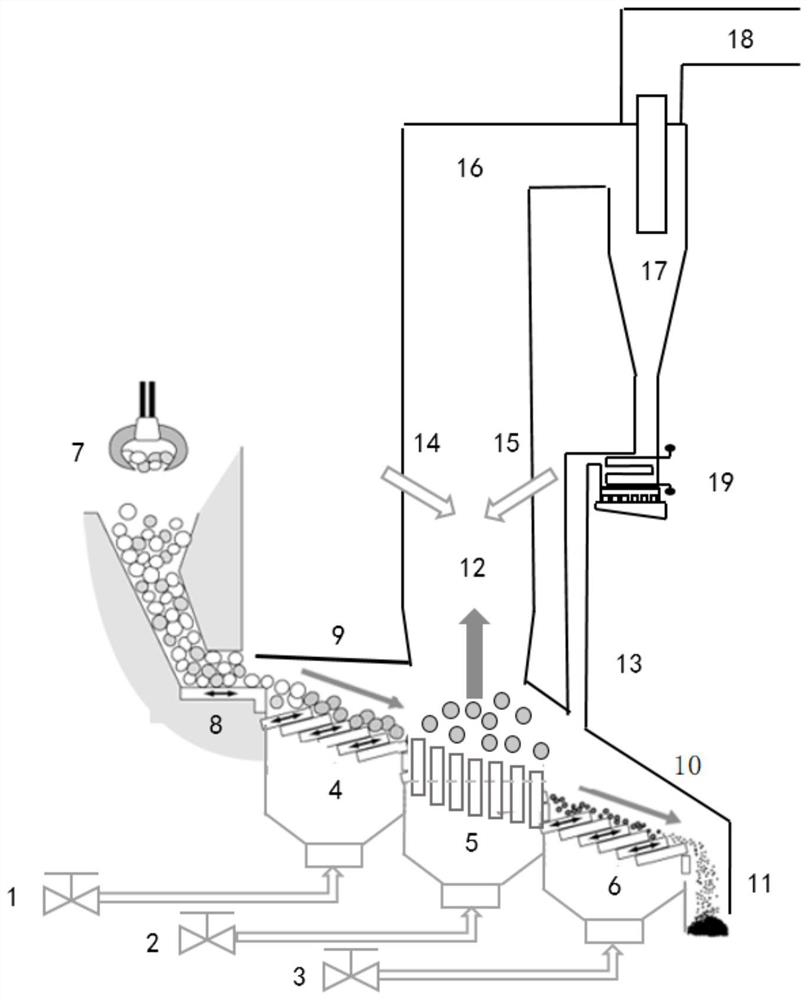

[0040] Such as image 3 , in this embodiment, the feeding system adopts the combination of feeding grab 7 and horizontal reciprocating feeding device 8, and the feeding grab 7 is arranged above the horizontal reciprocating feeding device 8, and the horizontal reciprocating feeding device 8 It is connected with the head end of the grate drying section 4, the tail end of the fire grate drying section 4 is connected with the head end of the fluidized combustion section 5, and the tail end of the fluidized combustion section 5 is connected with the head end of the fire grate burnout section 6, The tail end of the grate burnout section 6 is connected to the slag discharge pipe 11. The fluidized combustion section 5 adopts a fixed hood type, and several fixed hoods are arranged on the air distribution plate to better control the local small hole flow rate and realize the material flow at the same time. fluidized combustion.

[0041] The lower parts of the grate drying section 4, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com