Furnace temperature control method for coping with fluctuation of blast furnace gas utilization rate

A control method, blast furnace gas technology, applied in blast furnaces, blast furnace details, energy efficiency improvement, etc., can solve the problems affecting the quality of molten iron and the inability to effectively control the furnace temperature, and achieve the effect of ensuring the quality of molten iron and keeping the furnace temperature stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

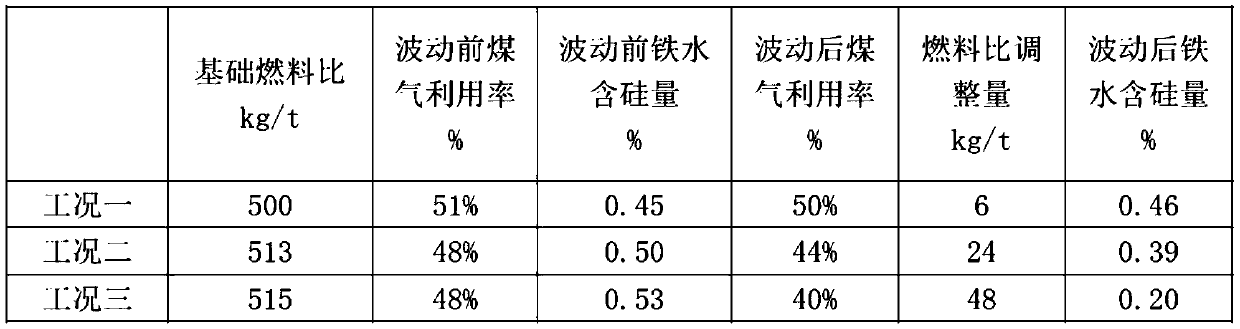

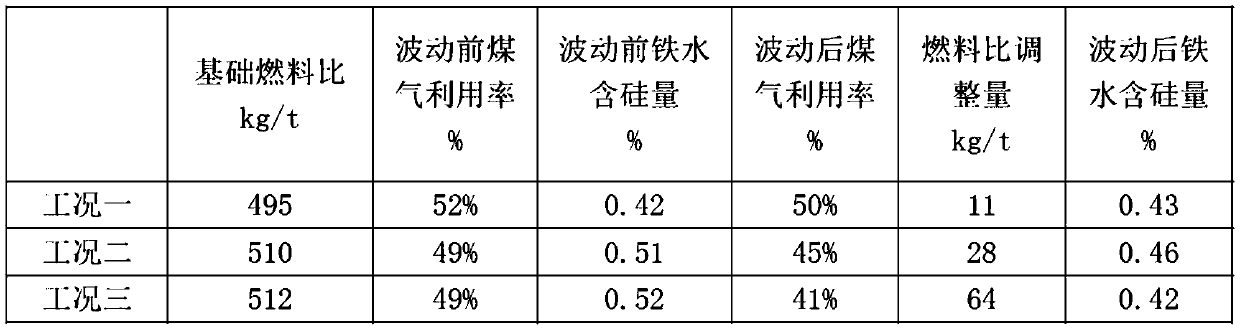

[0045] Under three different working conditions, adjust according to the method that the embodiment of the present invention provides, and concrete furnace condition is as shown in Table 2:

[0046] Table II

[0047]

[0048] It can be seen from the data in Table 2 that when the furnace temperature control method provided by the embodiment of the present invention is adopted, when the gas utilization rate fluctuates greatly, the furnace temperature changes before and after the fluctuation are small, thereby making the difference of silicon content in molten iron small. For example, if the fuel ratio is adjusted according to the prior art, when the blast furnace gas utilization rate is reduced from 48% to 40%, the furnace temperature will decrease by 0.32%; if the fuel ratio is adjusted using the method provided by the embodiment of the present invention, when the blast furnace gas utilization When the efficiency is reduced from 49% to 41%, the furnace temperature decreases ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com