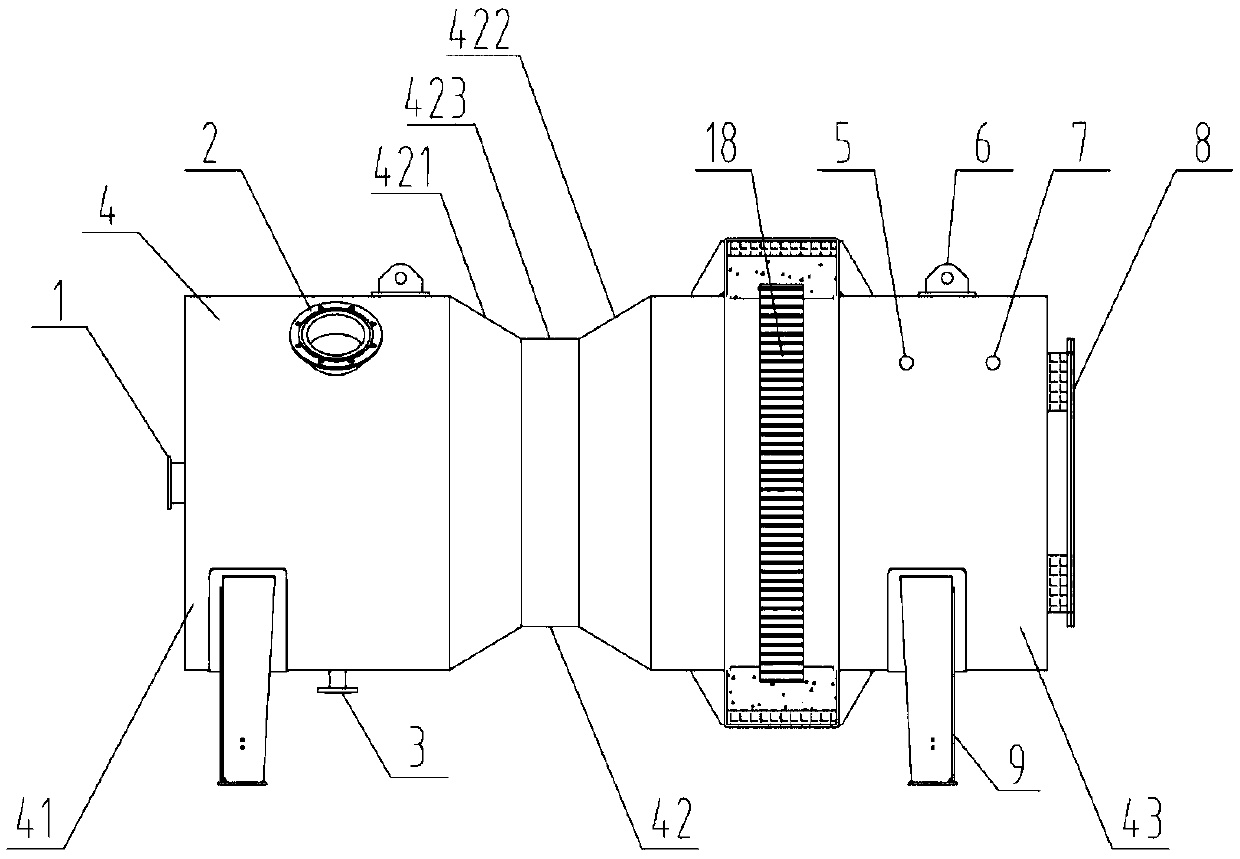

High-purity waste ammonia gas incinerating furnace, system and technology

A high-purity, incinerator technology, applied in the field of incinerators, can solve the problems that have not been fundamentally resolved, nitrogen oxides exceed the standard, and energy waste, so as to reduce the generation of NOX, prolong the service life, and avoid direct contact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

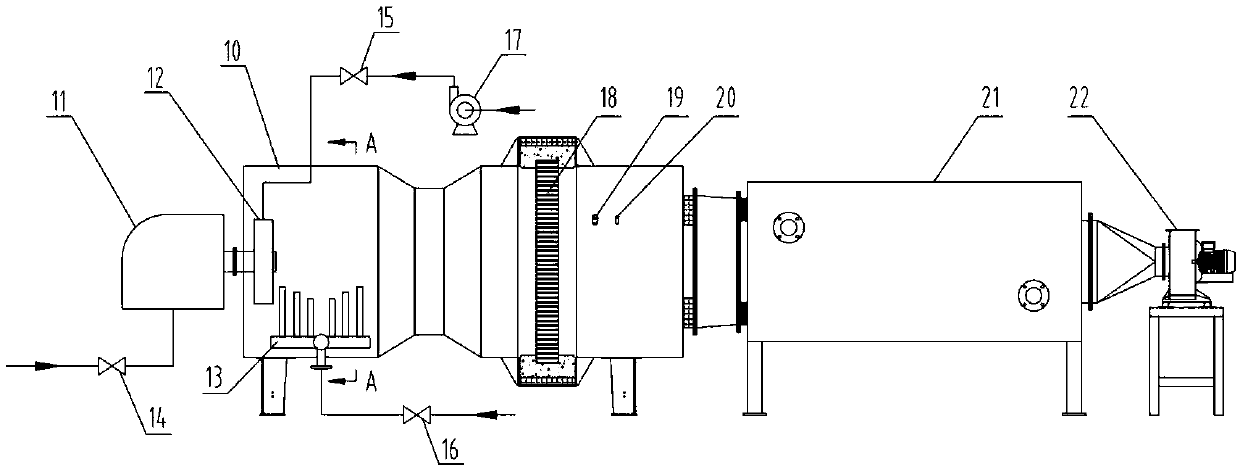

[0078] Embodiment 3 discloses a high-purity waste ammonia gas incineration system, which differs from Embodiment 2 mainly in that it does not include a finned tube heat exchanger 21 and a smoke exhaust fan 22. According to the requirements of working conditions, the flue gas from the incinerator 10 The outlet 8 is directly connected with the chimney through the flue. Compared with the high-purity waste ammonia gas incineration system described in Example 2, the corresponding incineration process reduces heat exchange and heat energy recovery, and reduces input costs. Others are basically the same and will not be repeated here.

[0079] A group of specific application test cases based on the high-purity waste ammonia incineration system described in Example 2 are given below:

[0080] Related parameters: waste ammonia concentration: 99.9%; maximum waste ammonia treatment capacity: 70kg / h; auxiliary fuel: hydrogen; circulating liquid: ethylene glycol aqueous solution; maximum ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com