Method for improving pulverized coal combustion performance and reducing NOx generation under O2/CO2 atmosphere

A pulverized coal combustion and CO2 technology, which is applied in combustion methods, combustion equipment, block/powder supply/distribution, etc., can solve the problems of incomplete combustion and unstable combustion, and achieve improved combustion performance and low NOx emissions. , to achieve the effect of NOx emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

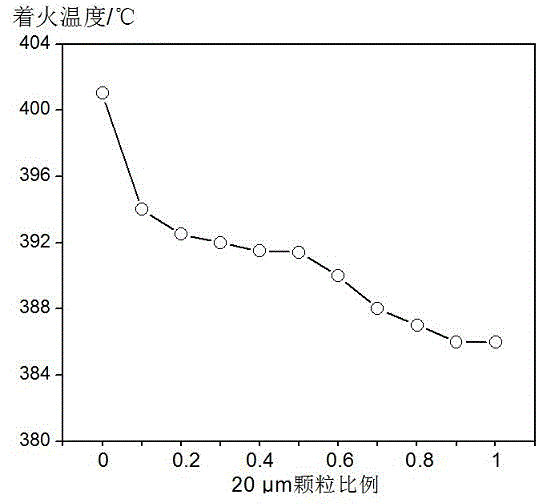

[0021] The ultra-fine pulverized coal in this embodiment adopts the Shenhua coal whose average particle diameter is 20 microns, and the ordinary particle diameter coal powder adopts the Shenhua coal whose average particle diameter is 74 microns. The industrial analysis of Shenhua Coal is shown in Table 1.

[0022] Table 1 Industrial Analysis of Shenhua Coal (mass / %)

[0023] name moisture Ash Volatile matter fixed carbon Shenhua Coal (SH) 4.80 5.00 31.90 58.30

[0024] Select 10% (mass percentage) of ultra-fine pulverized coal of this embodiment and 90% (mass percentage) of ordinary particle size pulverized coal in O 2 / CO 2 Mixed combustion under atmosphere, where O 2 / CO 2 O in the atmosphere 2 The mass percentage is 23.3%.

Embodiment 2

[0026]The average particle diameter that adopts in the present embodiment is that the superfine coal powder of 20 microns and the common particle diameter coal powder of 74 microns are the same as embodiment 1, and the difference is: in the present embodiment, the superfine coal powder 30% (mass percentage) and ordinary particle size pulverized coal 70% (mass percentage) in O 2 / CO 2 Mixed combustion under the atmosphere.

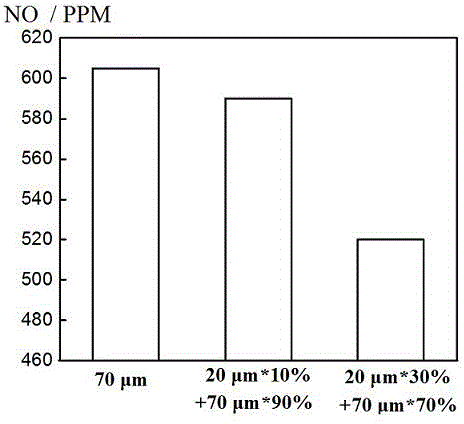

[0027] The combustion characteristic parameters of Example 1 and Example 2 are shown in Table 2, wherein the comparative example adopts the ordinary particle size coal powder combustion test with an average particle size of 74 microns.

[0028] Table 2 Combustion characteristic parameters of pulverized coal under different mixing ratios

[0029]

[0030] From the combustion characteristic parameters in Table 2, it can be seen that when 10% (mass percentage) ultra-fine coal powder is added to the ordinary particle size coal powder with an average part...

Embodiment 3

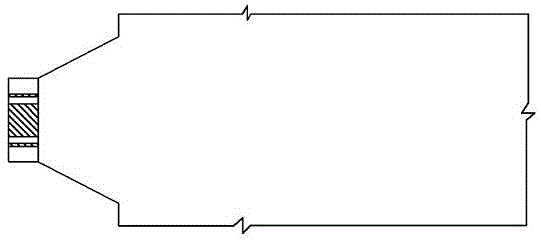

[0034] In this embodiment, a pulverized coal burner (such as figure 2 As shown), the combustion process of the internal mixed pulverized coal is calculated and studied, in which the primary air carries the pulverized coal and is injected into the combustion chamber, and there is secondary air to support the combustion. In this embodiment, 10% (mass percentage) of ultra-fine coal powder with an average particle size of 20 μm and 90% (mass percentage) of ordinary particle size coal powder with an average particle size of 70 μm are mixed in O 2 / CO 2 Mixed combustion under the atmosphere. The analysis of coal powder composition is shown in Table 3. The combustion conditions are shown in Table 4.

[0035] Coal type composition analysis in table 3 embodiment 3

[0036]

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com