Combined cycle thermodynamic system based on coupling of light gas turbine and biomass direct-fired fire grate type boiler

A thermal system and combined cycle technology, applied in the direction of combined combustion mitigation, combustion methods, mechanical equipment, etc., can solve the problems of high production, high combustion temperature, and low ash melting point, so as to improve adaptability, expand application scenarios, reduce The effect of heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

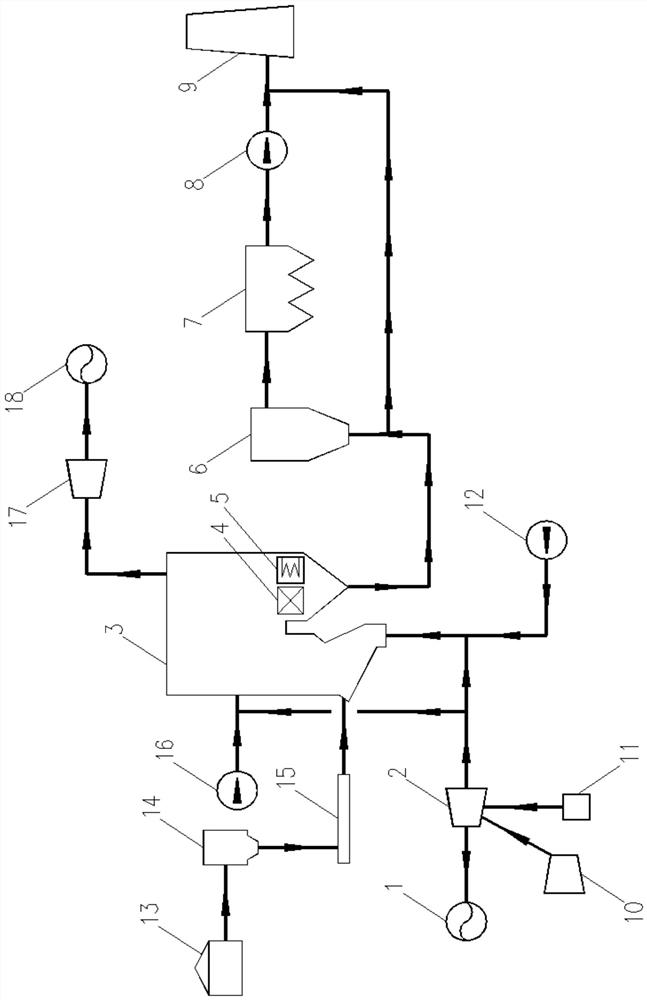

[0055] refer to figure 1 , when the light gas turbine 2 and the biomass direct-fired grate boiler 3 are in normal operation, the natural gas at the outlet of the natural gas pressure regulating station 11 and the high-pressure air at the outlet of the air compressor 10 burn in the light gas turbine 2 and drive the gas turbine-driven generator 1 to generate electricity , the high-temperature flue gas directly enters the hot primary air inlet below the biomass direct-fired grate boiler 3 through the flue, mixes with the cold air from the outlet of the primary fan 12, and then dries and preheats the biomass fuel rolled down to the grate , part of the fuel begins to decompose and burn on the grate. The secondary air is boosted by the blower 16 and sent to the top of the furnace, and is sprayed into the furnace at the same position as the high-temperature flue gas to disturb the combustion zone while supplementing enough oxygen to ensure that the unburned part of the biomass and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com