Aluminum ash deamination device and aluminum ash deamination process

A technology for aluminum ash and deamination, applied in the field of aluminum ash treatment, can solve the problems of high cost, low deamination efficiency of aluminum ash, difficult subsequent treatment, etc., and achieves extended service life, less operating noise, and improved heating efficiency and speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

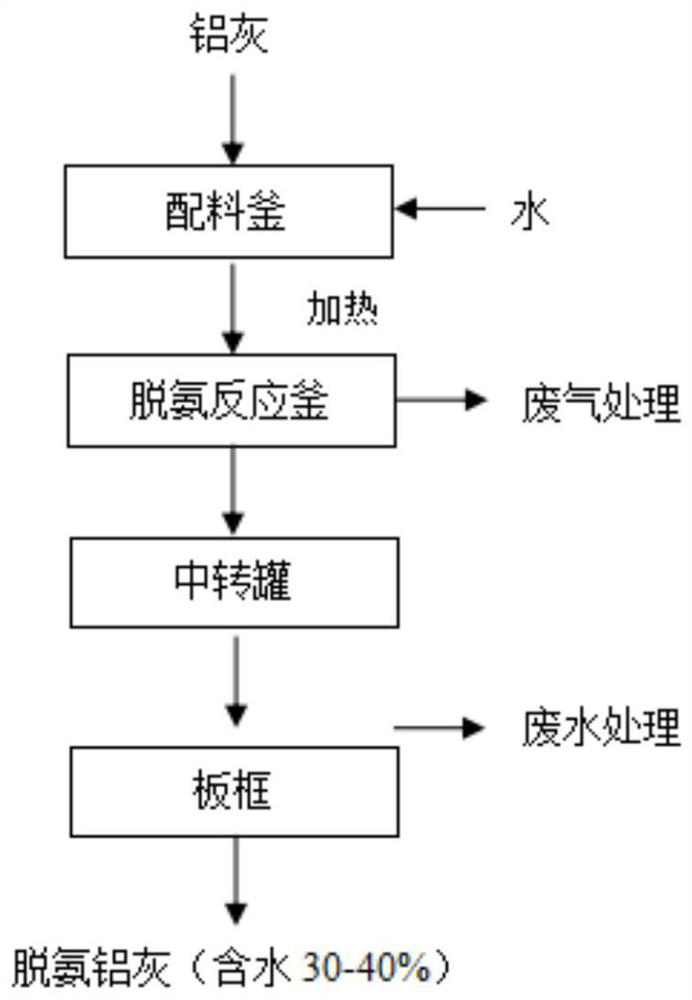

[0039] A kind of aluminum ash deaminization process, comprises the following steps:

[0040] Add 3.5 tons of aluminum ash to the deamination unit, add 0.025 tons of quicklime powder, 0.01 tons of sodium thiosulfate, add 0.7 tons of dedusting water, add 0.3 tons of cleaning water, open the high-temperature exhaust valve, close the dedusting and exhaust valve, and heat the components The material was heated to 50°C, the material began to react violently, and a large amount of ammonia gas was discharged, and after waiting for 10 minutes, the reaction was gentle. Continue to add 0.5 tons of dedusting water and 1.5 tons of new water. After the temperature rises to 70°C, there is no violent reaction. Close the dedusting exhaust valve, and the pressure rises to 0.1Mpa. Partially open the pressure relief valve, and adjust the internal pressure to 0.15Mpa. Pressurize and react for 2.5 hours, open the dust removal exhaust valve, close the high temperature exhaust valve, open the unloadi...

Embodiment 2

[0042] A kind of aluminum ash deaminization process, comprises the following steps:

[0043] Add 2.5 tons of aluminum ash to the deamination unit, add 0.015 tons of slaked lime powder, 0.005 tons of sodium sulfate, add 0.6 tons of dedusting water, add 0.2 tons of new water, open the high-temperature exhaust valve, close the dedusting and exhaust valve, and heat the components to remove the material When heated to 40°C, the material began to react violently, and a large amount of ammonia gas was discharged. After waiting for 10 minutes, the reaction was gentle. Continue to add 0.5 tons of dedusting water and 0.7 tons of new water. After the temperature rises to 60°C, there is no violent reaction. Close the dedusting exhaust valve, and the pressure rises to 0.12Mpa. Partially open the pressure relief valve, and adjust the internal pressure to 0.18Mpa. Pressurize and react for 1.5 hours, open the dust removal exhaust valve, close the high temperature exhaust valve, open the unloa...

Embodiment 3

[0045] A kind of aluminum ash deaminization process, comprises the following steps:

[0046] Add 3.8 tons of aluminum ash to the deamination unit, add 0.05 tons of stone powder, 0.015 tons of magnesium sulfate, add 0.8 tons of dedusting water, add 0.3 tons of cleaning water, 0.4 tons of new water, open the high-temperature exhaust valve, close the dust removal and exhaust valve, The heating unit heats the material to 70°C, the material begins to react violently, and a large amount of ammonia gas is discharged. After waiting for 10 minutes, the reaction is gentle. Continue to add 0.6 tons of dedusting water, and add 1.2 tons of new water. After the temperature rises to 80°C, there is no violent reaction. Close the dedusting exhaust valve, and the pressure rises to 0.08Mpa. Partially open the pressure relief valve, and adjust the internal pressure to 0.12Mpa. Pressurize and react for 1.5 hours, open the dust removal exhaust valve, close the high temperature exhaust valve, open t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com