Device for removing dioxin from flying garbage dust and treatment method of device

A technology of waste fly ash and dioxin, applied in the combustion method, combustion type, incinerator, etc., can solve the problems of harming the environment, market irregularity, and inadequate supervision, and achieves a high degree of automation, high investment efficiency, and high occupation. The effect of less ground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

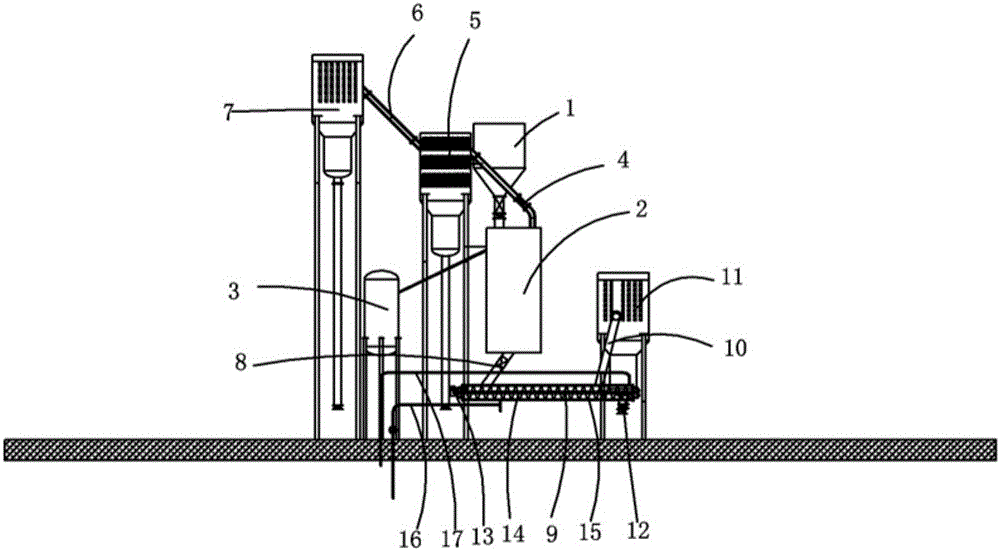

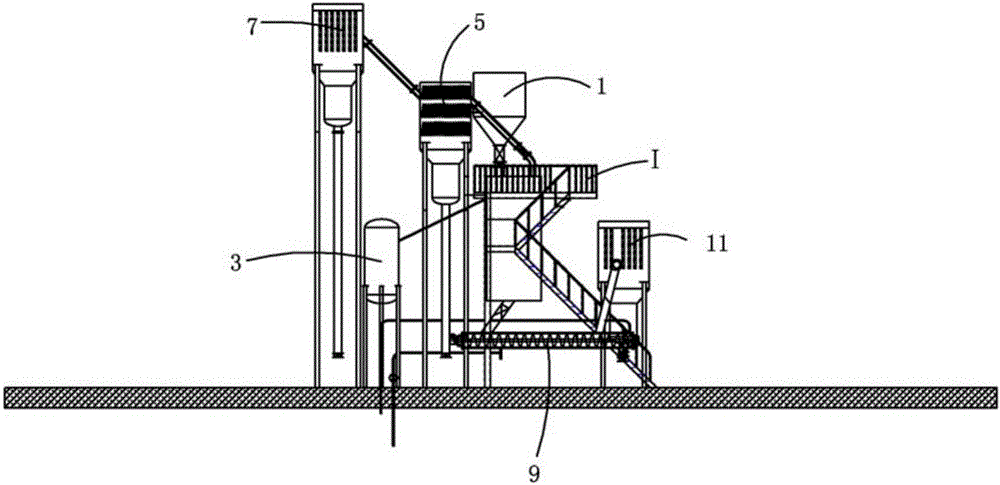

[0026] Examples, see attached Figure 1~2 , a dioxin removal device for garbage fly ash, including a silo 1, a steel platform I for manual use is installed on the floor of the workshop, and the silo is equipped with a manual feeding port for initial detection and quantitative use, and the silo is a hopper structure.

[0027] The discharge opening of described silo is connected with pyrolysis furnace 2, and pyrolysis furnace is connected with nitrogen replenishment tank 3, makes in the sealing environment of nitrogen protection gas in the pyrolysis furnace; When pyrolysis furnace works, need to use nitrogen as Working under the action of protective gas, the furnace of the thermal decomposition furnace is made of stainless steel, and the effective volume in the furnace is greater than 0.8m 3 . The maximum working temperature of the pyrolysis furnace is 450°C, and the temperature of the shell of the pyrolysis furnace is less than 20°C, which is safe and reliable during operatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com