Device for semiconductor laser unit Zn impurity source diffusion and application thereof

A laser and impurity source technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as poor process repeatability, insufficient diffusion depth, and unfavorable devices, and achieve uniform distribution of Zn concentration, good repeatability, and ensure The effect of furnace temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

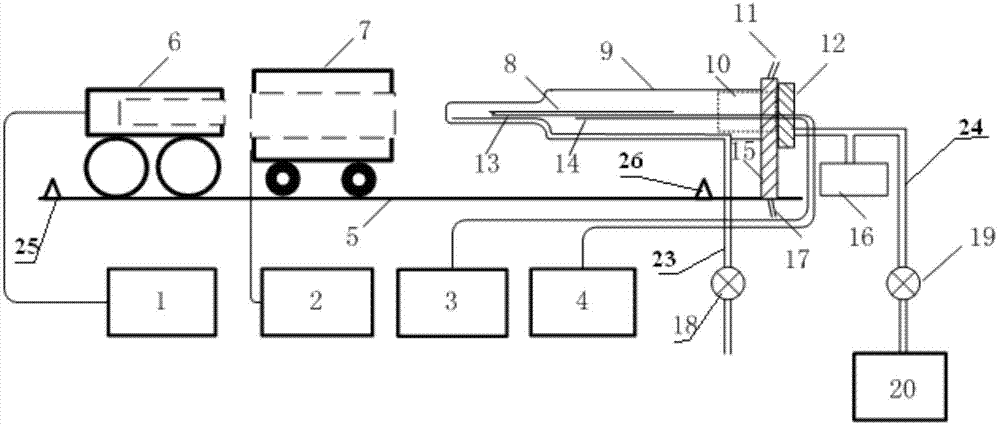

Embodiment 1

[0041] A device for diffusion of semiconductor laser Zn impurity sources, comprising a first diffusion heating furnace 6 and a second diffusion heating furnace 7 arranged in sequence on a track 5; the first diffusion heating furnace 6 is a groove shape with one end closed, so The second diffusion heating furnace 7 is hollow and annular; at one end of the track 5, a support 15 is arranged behind the second diffusion heating furnace 7, and a quartz with one end closed and one end open is installed on the support 15. Tube 9, on the side wall of described quartz tube 9, is provided with the ventilation pipe 23 that supplies nitrogen gas to fill, and is provided with N on the described ventilation pipe. 2 Valve 18; An annular sealed quartz tube 10 is installed at the open end of the quartz tube 9, and the sealed quartz tube 10 is sealed at the open end of the quartz tube 9 by a quartz tube sealing cover 12; 9, the first thermocouple 13 and the second thermocouple 14 are arranged in...

Embodiment 2

[0047] A device for diffusing Zn impurity sources of semiconductor lasers as described in Embodiment 1, the difference is that a first stopper 25 is arranged at one end of the track 5 and in front of the first diffusion heating furnace 6 ; At the other end of the track 5 and below the quartz tube 9, a second limiter 26 is provided.

Embodiment 3

[0049] A kind of application of the device of semiconductor laser Zn impurity source diffusion as described in embodiment 1, the steps are as follows:

[0050] (1) Turn on the main power of the device and turn on the temperature controller a1 and temperature controller b2 for heating, push the first diffusion heating furnace 6 and the second diffusion heating furnace 7 along the track 5 to the end away from the quartz tube 9, and heat And constant temperature to the set temperature required for the diffusion source and laser chip diffusion; dual temperature zones are used to control the temperature of the diffusion source and the chip, which are controlled separately during the diffusion process to ensure the stability of the furnace temperature, which can prevent the GaAs on the surface of the laser chip from being in a large amount at the diffusion temperature. decompose;

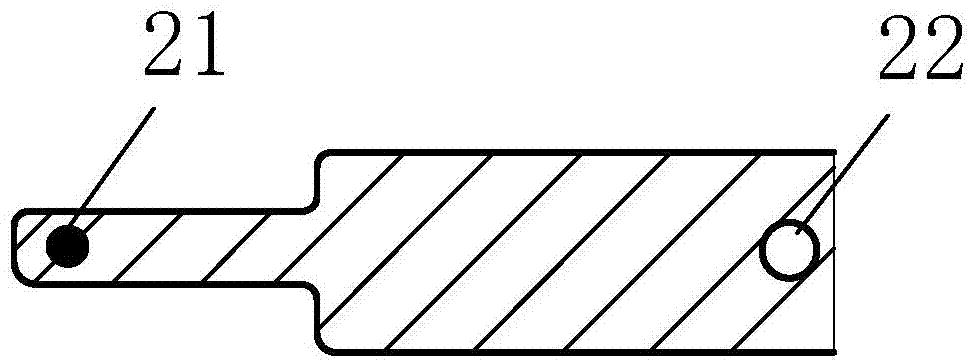

[0051] (2) Put the weighed Zn diffusion source into the source groove 21 of the quartz boat 8, place t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com