Method for burning sludge of chain furnace

A technology for incinerating sludge and chain furnace, applied in the combustion method, incinerator, combustion type and other directions, can solve the problems of insufficient heat source, stable furnace temperature interference, boiler steam pressure drop, etc., and achieve easy ignition and incineration, effective heating value The effect of utilizing and improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below by means of embodiments in conjunction with the accompanying drawings.

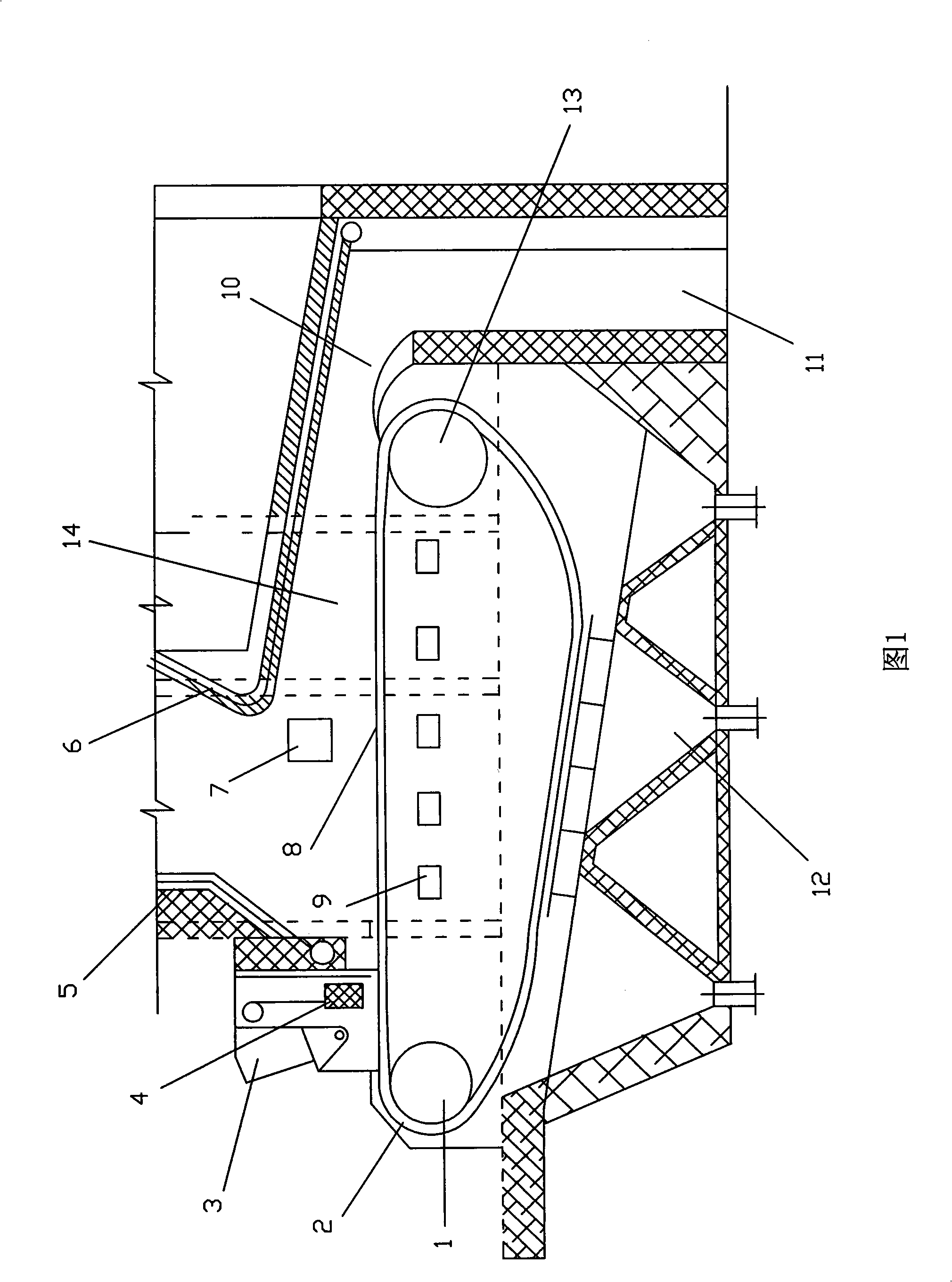

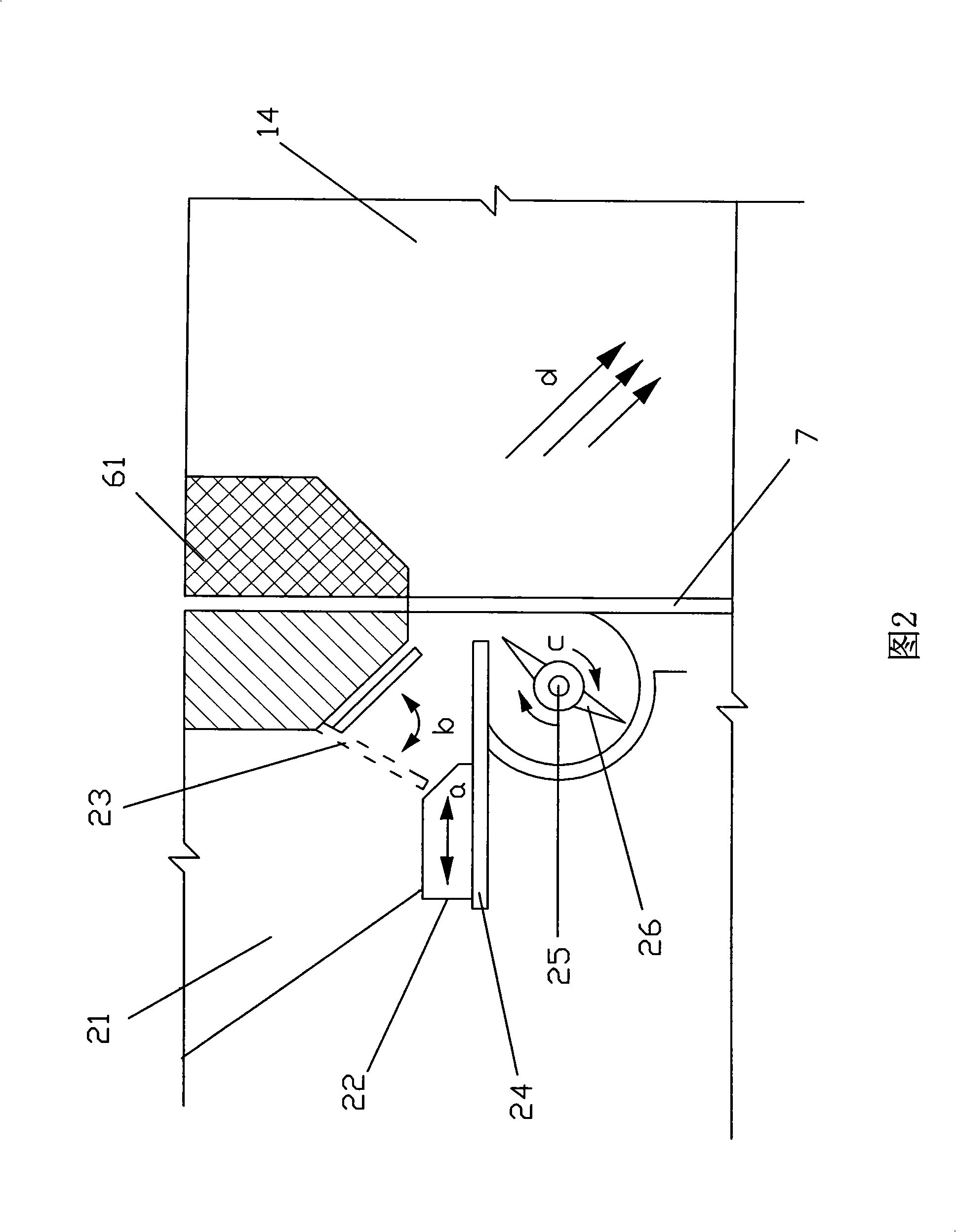

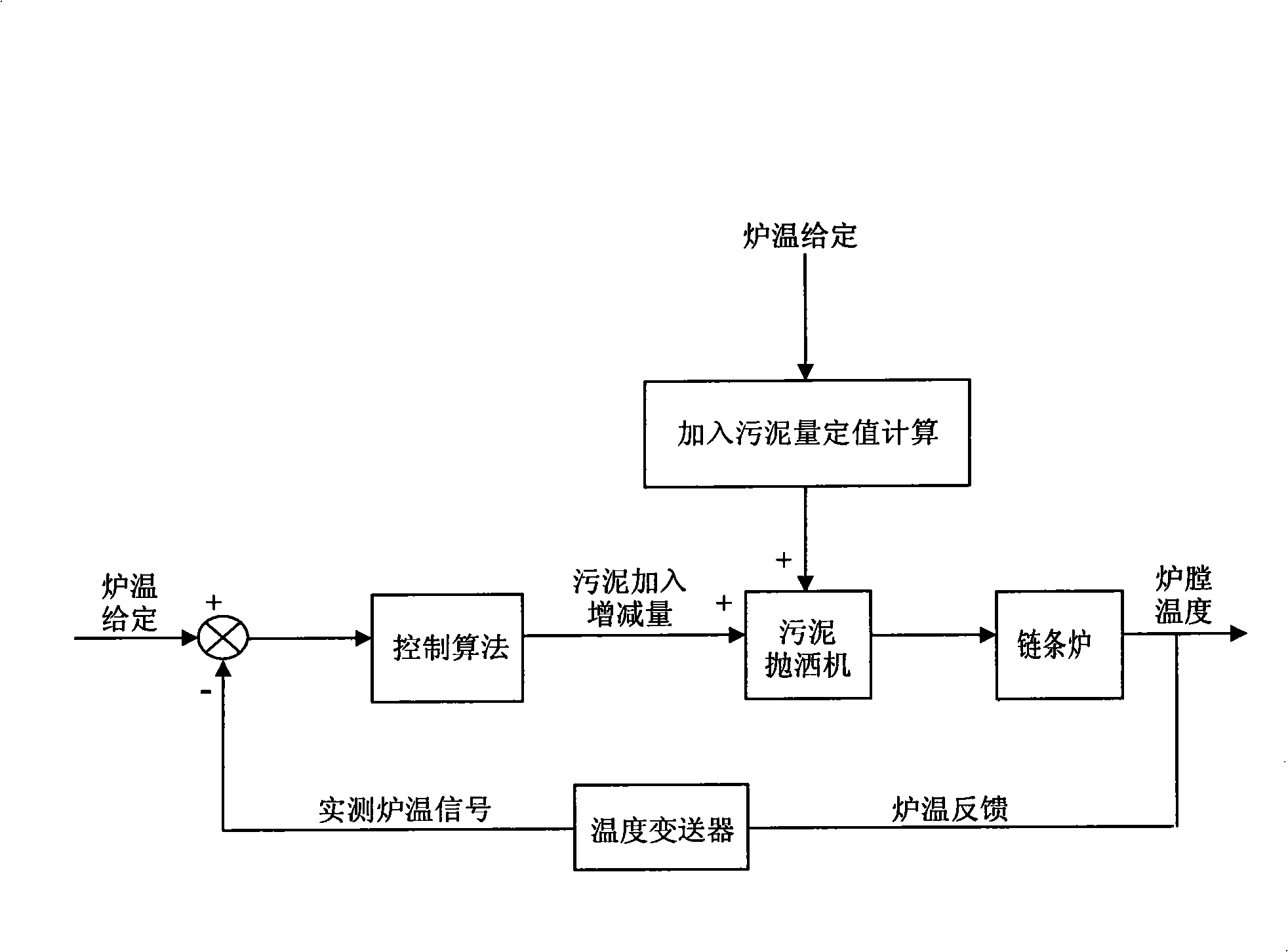

[0016] Referring to Fig. 1, the method for incinerating sludge in the chain furnace adopts a sludge throwing inlet 7 at the back arch of the side of the chain furnace, and coal and sludge are added to the hearth 14 of the chain furnace respectively. The coal is fed into the chain grate 2 of the chain furnace from the coal hopper 3 located in front of the furnace through the coal gate 4, and the coal is preheated, dried, and ignited sequentially with the movement of the chain grate 2; Sludge with a content of 15% to 60% is evenly added to the chain furnace from the sludge throwing inlet 7, and the sludge falling point 8 is located at the tail of the chain furnace hearth 14, which is one-half to three-quarters of the chain furnace grate 2 Near the rear arch 6, the sludge added here utilizes the furnace temperature at the end of the chain furnace h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com