Concrete mixing plant for hydraulic engineering construction

A technology of mixing equipment and water conservancy engineering, which is applied in cement mixing devices, clay preparation devices, batching weighing instruments, etc., can solve the problems of inability to dissipate heat from concrete in mixing drums, without raw material weighing and measurement, and large raw material ratio errors. , to achieve the effect of reducing dust splashing, increasing sealing and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

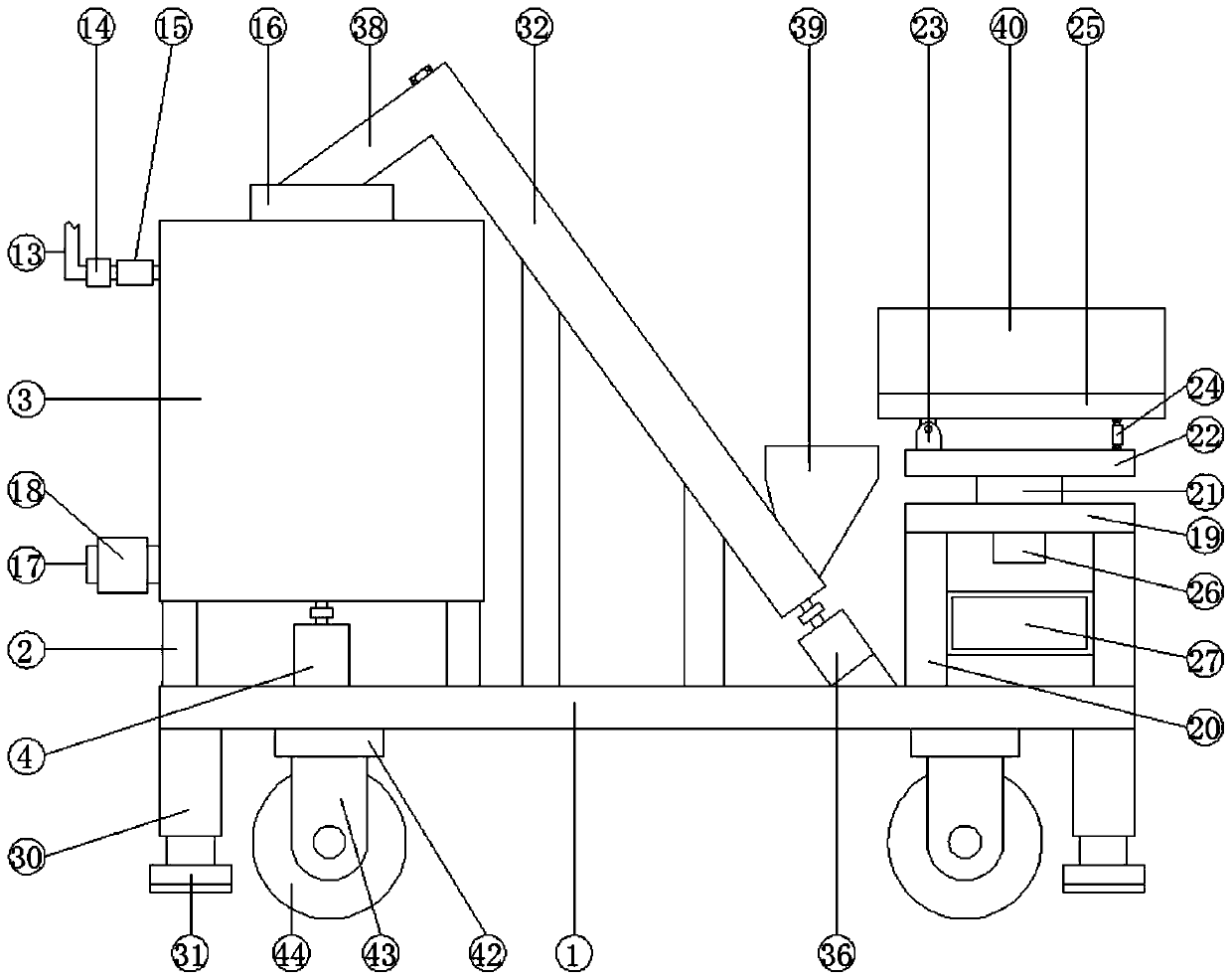

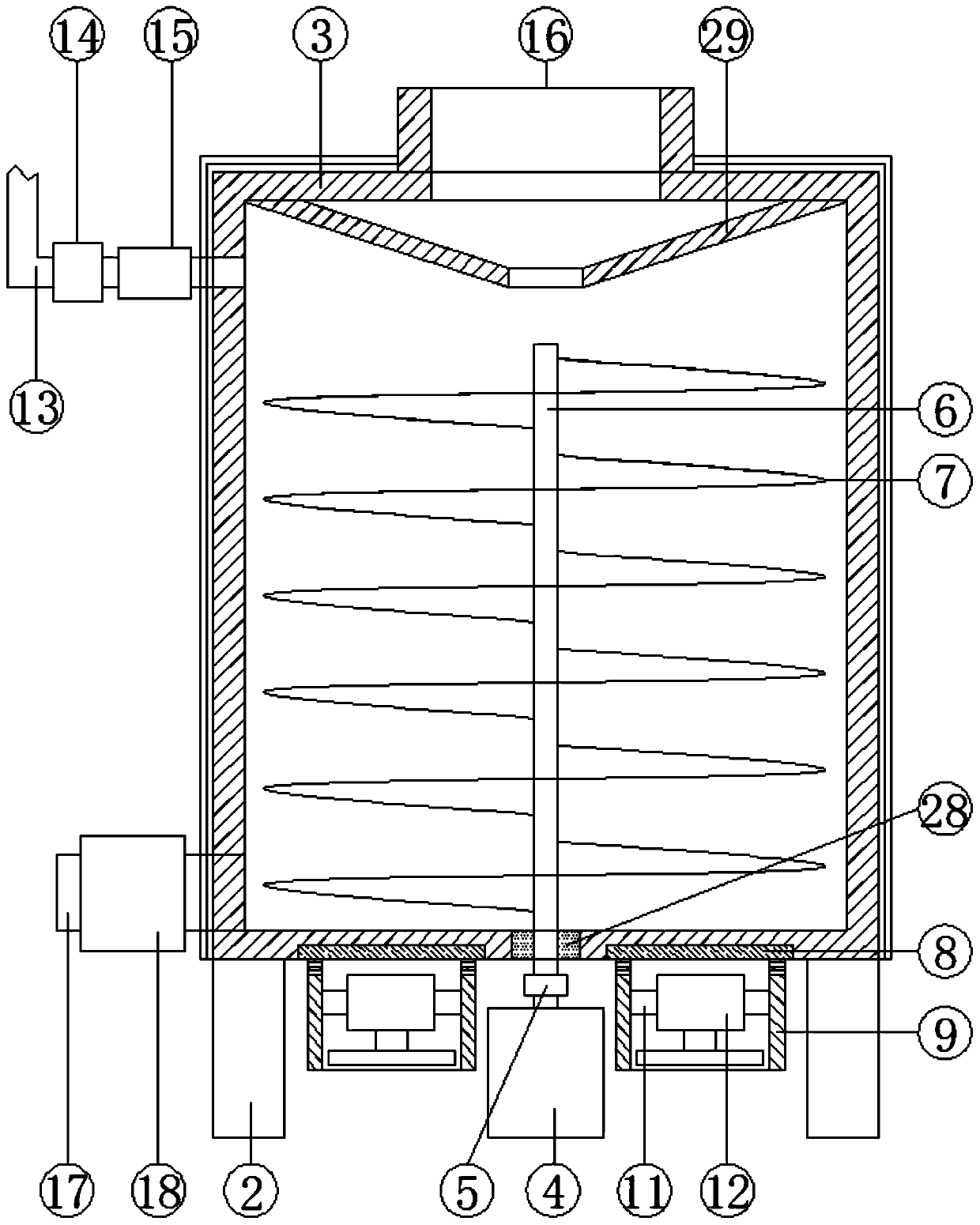

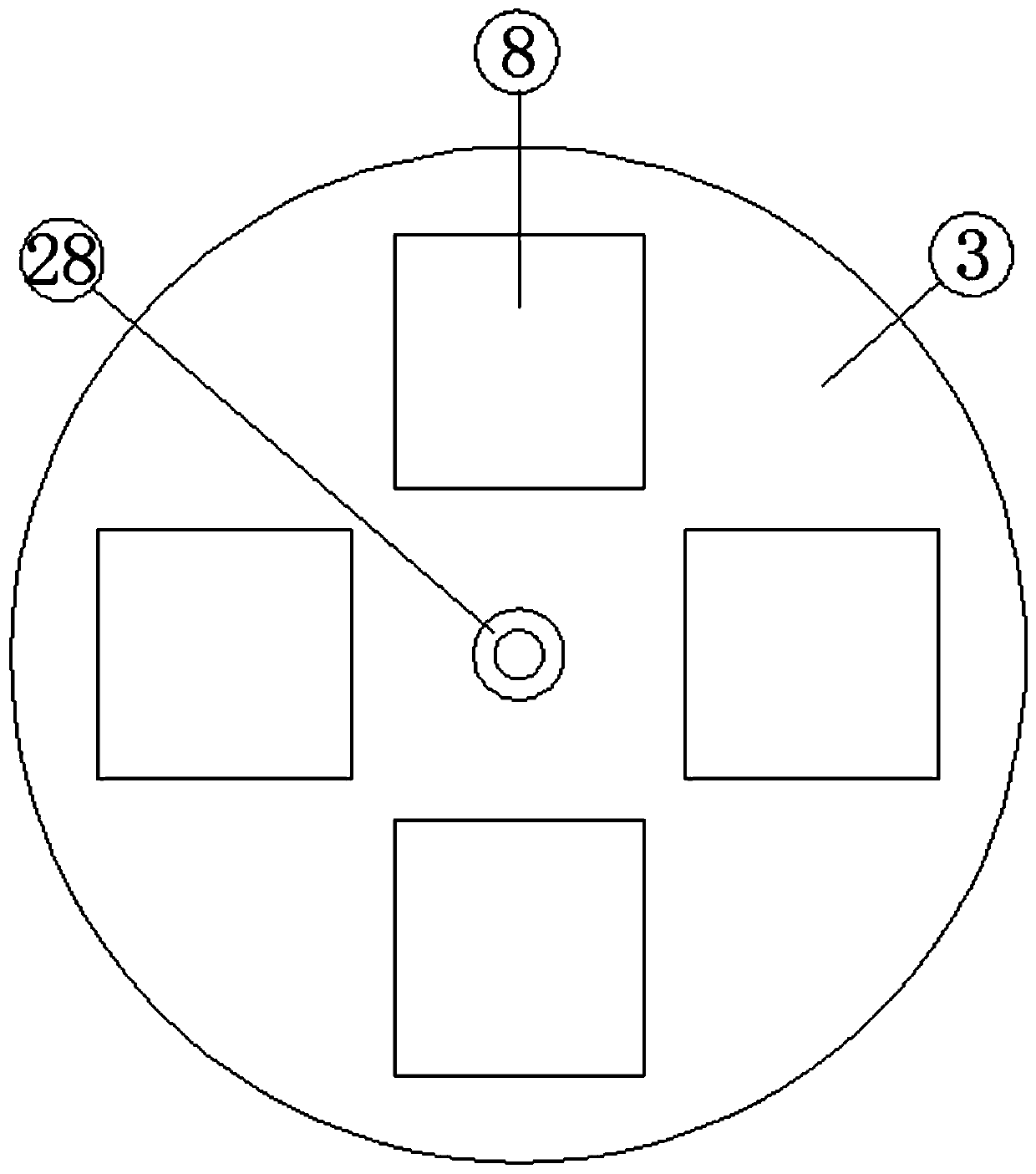

[0035] see Figure 1-6According to an embodiment of the present invention, a concrete mixing equipment for hydraulic engineering construction includes a base 1, a mixing drum 3 is fixed on the base 1 through a first connecting rod 2, and a first motor is fixed on the base 1 4. The rotating shaft of the first motor 4 is fixed with a transmission shaft 6 through the first coupling 5, and the transmission shaft 6 penetrates the bottom end of the mixing drum 3 and extends into the mixing drum 3, and the transmission shaft 6 The outer wall of the upper end of the shaft 6 is fixed with a number of spiral stirring blades 7, and the outer wall of the bottom end of the mixing drum 3 is fixedly embedded with four semiconductor refrigerators 8 at equal intervals along the circumferential direction. There is a cylinder 9, the upper end of the cylinder 9 is provided with a number of air intake holes 10, the inside of the cylinder 9 is fixed with a cooling fan 12 through the second connecti...

Embodiment 2

[0038] see Figure 1-2 , for the mixing drum 3, the middle part of the bottom end of the mixing drum 3 is fixedly embedded with a sealing ring 28 and the sealing ring is sleeved on the outer wall of the transmission shaft 6; for the mixing drum 3, the upper end of the mixing drum 3 The inner wall is fixed with a splash-proof tube 29, and the splash-proof tube 29 is a hollow inverted round table-shaped structure; for the mixing drum 3, the outer wall of the mixing drum 3 is fixed with sound-absorbing cotton, and the outer wall of the sound-absorbing cotton is fixed with Sound insulation cotton.

[0039] Through the above scheme of the present invention, the sealing ring 28 can increase the sealing between the transmission shaft 6 and the bottom end of the mixing drum 3, and the splash-proof drum 29 can effectively reduce the dust splashing during the stirring process, thereby improving the working environment and sound absorption. Cotton and sound insulation cotton can absorb ...

Embodiment 3

[0041] see figure 1 , 5 and 6, for the feeding device, the feeding device includes a feeding tube 32, the feeding tube 32 is fixed on the base 1 through several third connecting rods, and the inside of the feeding tube 32 can be rotated A rotating shaft 33 is provided, the outer wall of the rotating shaft 33 is fixed with dragon blades 34, the base 1 is fixed with a motor mount 35, and the motor mount 35 is fixed with a second motor 36. The rotating shaft of two motors 36 is fixedly connected with the lower end of the rotating shaft 33 through the second coupling 37, the upper end of the feeding cylinder 32 is connected with a discharge pipe 38 and the lower end of the discharge pipe 38 is connected with the feed inlet 16 connected, the lower end of the feeding tube 32 is fixed with a hopper 39, and the storage plate 25 is matched with the hopper 39; for the storage plate 25, both sides of the storage plate 25 are fixed with side plate 40 , and an end plate 41 is fixed at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com