Novel furnace bottom distributor of sieve-plate-free fluidizing chlorination furnace

A technology of boiling chlorination furnace and chlorine gas distributor, which is applied in the direction of titanium halide, etc., to achieve the effect of increasing the range of material selection, improving stability and continuity, and stabilizing furnace temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

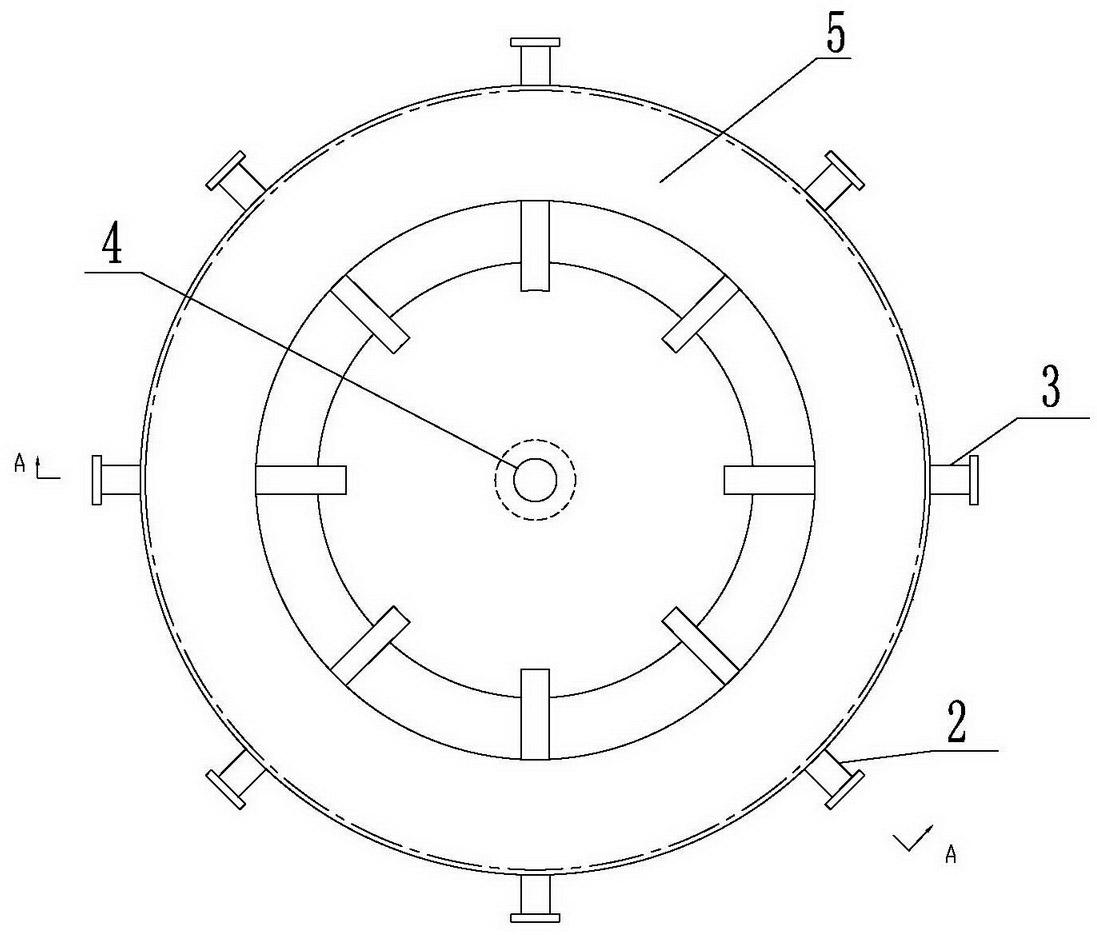

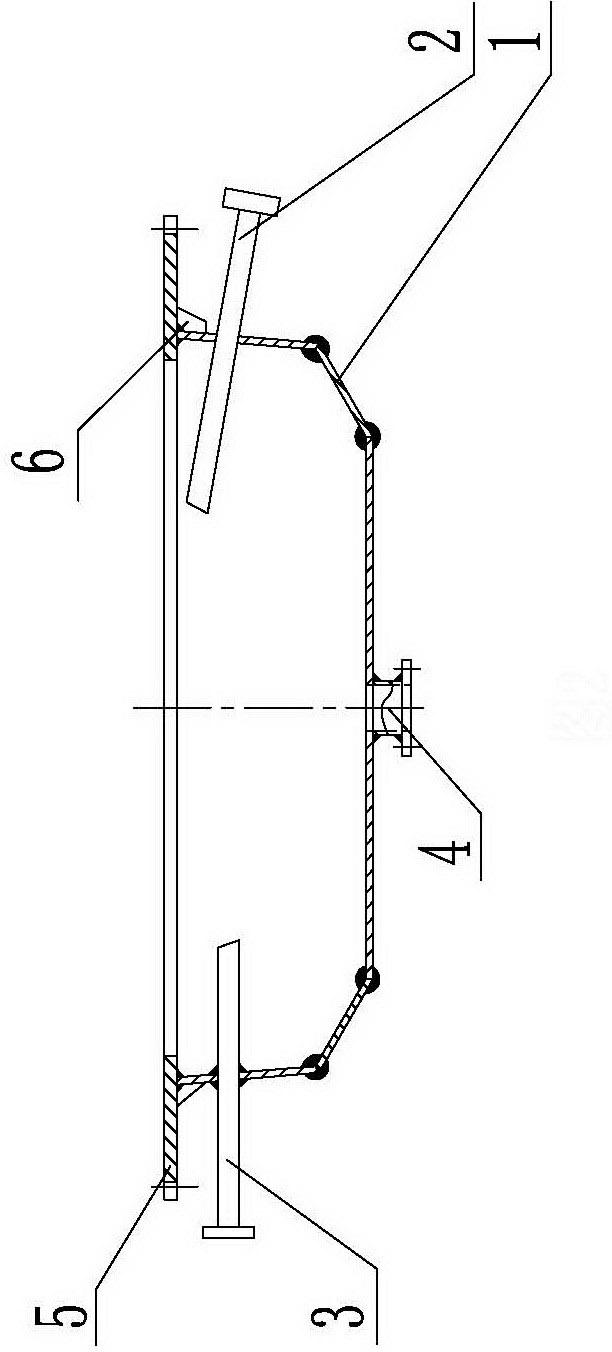

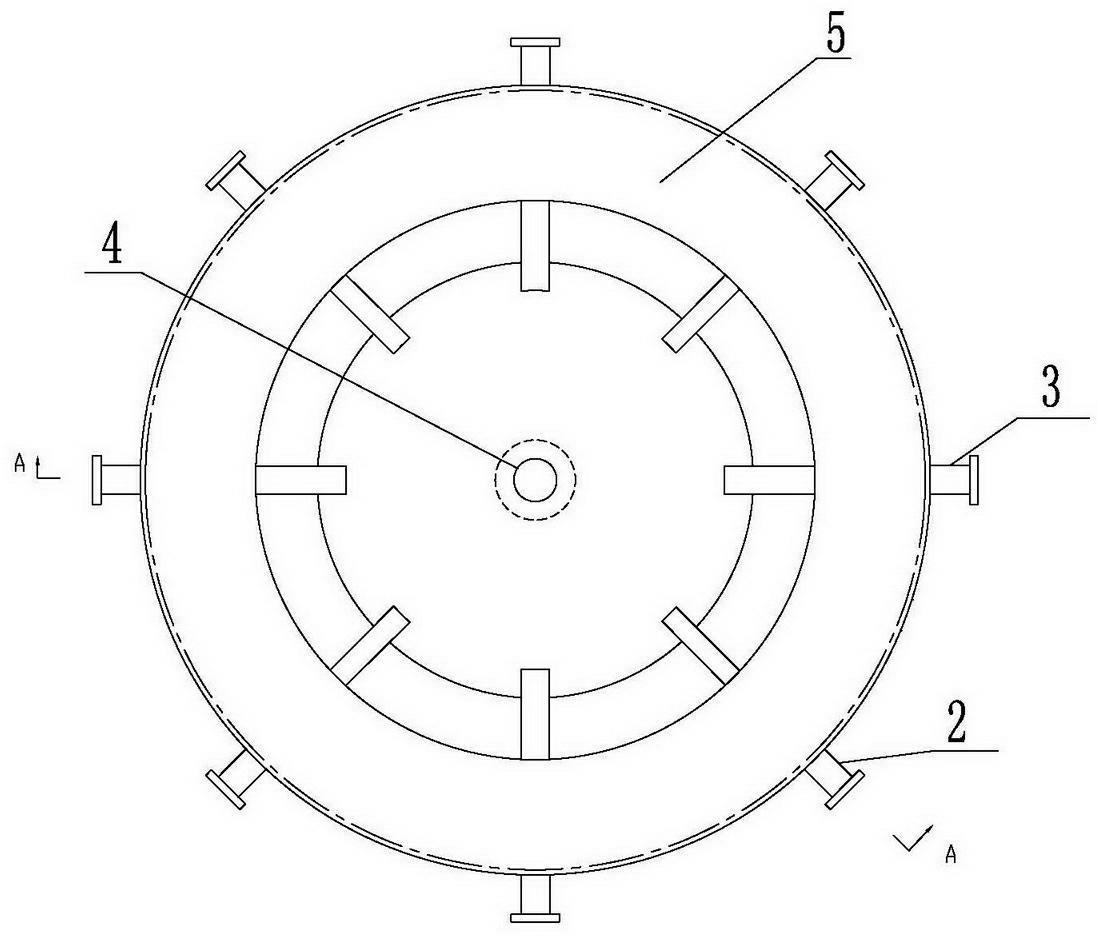

[0008] As shown in the figure, the present invention includes a pot-shaped housing 1, the outer edge of the upper end of the housing 1 is provided with a connecting flange 5 for connecting with the chlorination furnace, and a reinforcement is provided between the connecting flange 5 and the housing 1. Rib 6. The lower end of the casing 1 is provided with a slag discharge pipe 4 . A number of chlorine gas straight-through pipes 3 and chlorine gas oblique pipes 2 are provided along the side of the housing 1, wherein the chlorine gas straight-through pipes 3 are arranged horizontally; -45° angle. The total number of chlorine gas straight-through pipes 3 and chlorine gas inclined pipes 2 is 8-16, and each accounts for half. Chlorine gas straight-through pipe 3 and chlorine gas inclined pipe 2 pipe diameters are 1 cun-57mm, and the length inserted into the bottom of the furnace is 400-500mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com