Immersed top-blown converter

A top-blown converter and submerged technology, which is applied in the manufacture of converters, etc., can solve the problems of small gun head, complicated operation, complex furnace structure, etc., and achieve the effects of reducing heat loss, uniform material mixing, and improving reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

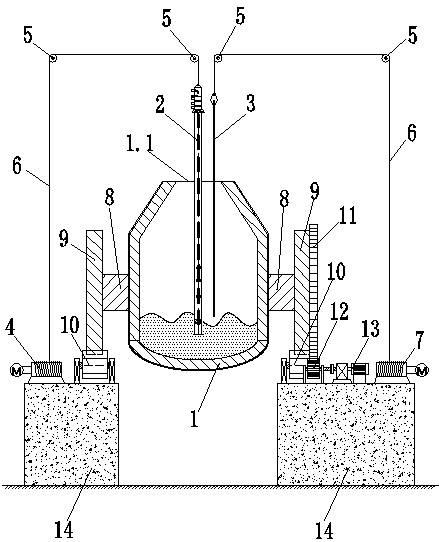

[0052] Embodiment 1: as figure 1 As shown, a submerged top-blown converter includes a top-blown converter body 1. The bottom of the top-blown converter body 1 is a head, the lower part is a straight barrel section, the upper section is a variable-diameter section that shrinks from bottom to top, and the top is a furnace mouth 1.1 . A submerged top-blowing spray gun 2 and a detection rod 3 are inserted into the furnace mouth 1.1. Furnace port 1.1 meets the functional requirements of feeding, smoke exhaust, slag discharge and metal discharge. The main body 1 of the top-blown converter is connected to the supporting ring 9 through the support lug 8, the supporting ring 9 is supported on the idler roller 10, the idler roller 10 is supported on the rotating support seat of the furnace, and the rotating support is fixed on the concrete support pier 14, and the driving end The large support ring 9 is connected with the large gear ring 11, the large gear ring 11 and the small gear r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com