Coal fine preparation, blowing method and device from packed-bed smelting reduction furnace

A technology for pulverized coal preparation and reduction furnace, applied in the field of smelting reduction ironmaking, can solve problems such as large pollution and large investment scale, and achieve the effects of reducing production costs, reducing coal consumption costs, and optimizing the smelting reduction process.

Active Publication Date: 2010-12-01

BAOSTEEL ENG & TECH GRP +1

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In order to solve the problems of large-scale investment and heavy pollution in the traditional blast furnace ironmaking method, since the 1970s, a COREX furnace ironmaking method, namely the smelting reduction ironmaking method, has been developed in the world.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

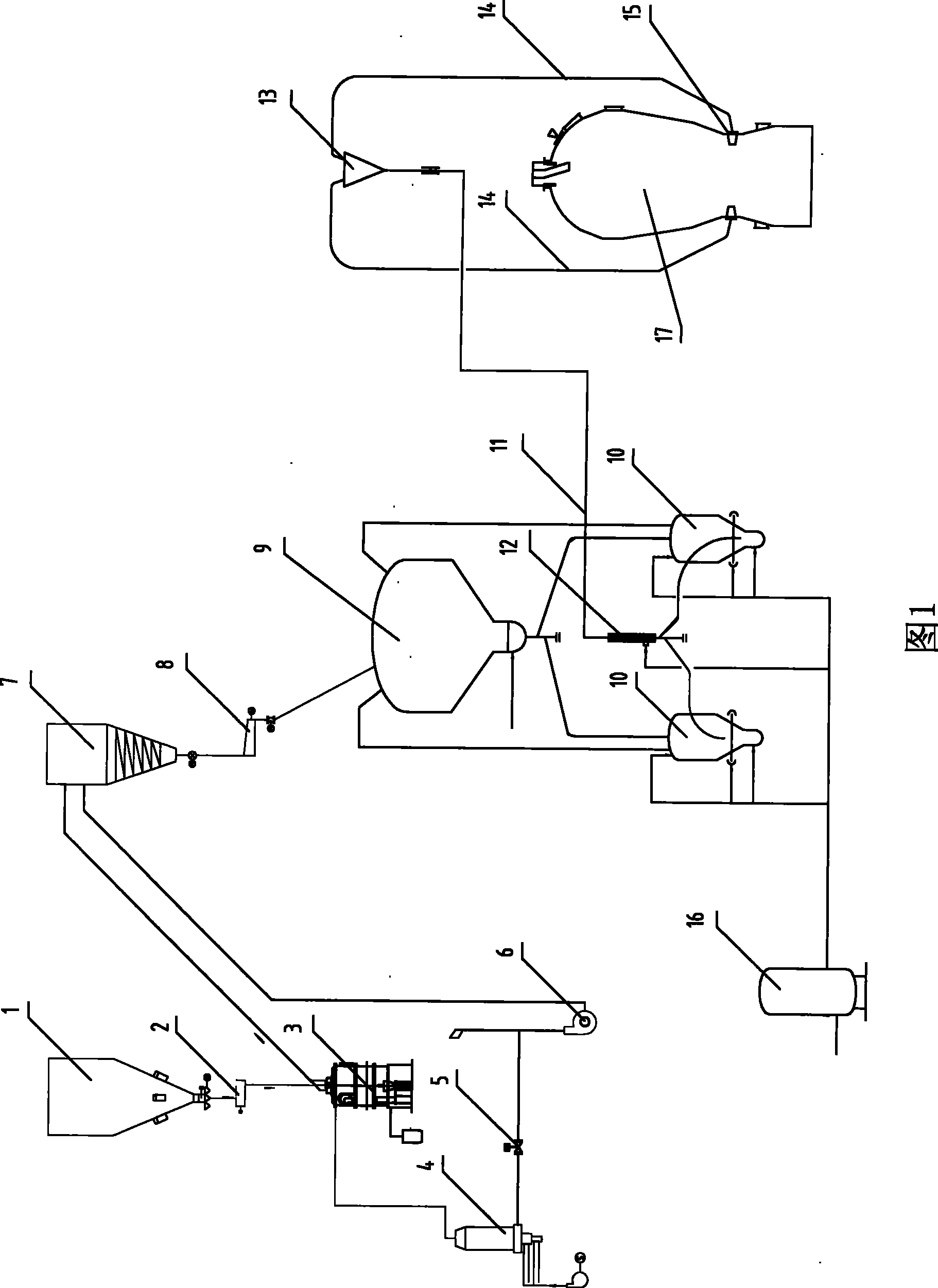

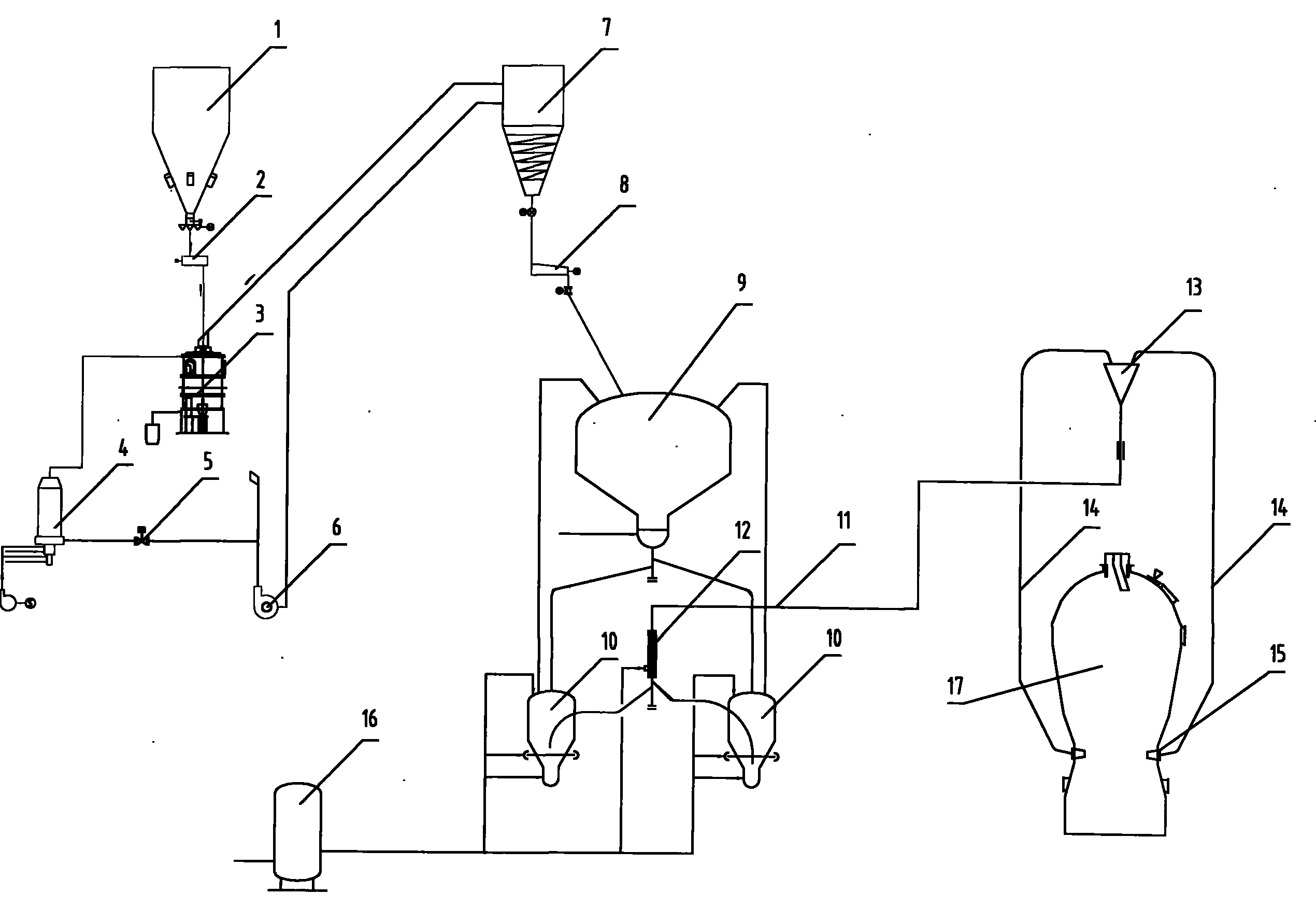

The invention discloses a filling bed COREX stove braise preparing and blowing method which comprises the following steps of: a) putting mine run coal which is applicable to melting in the COREX stove and producing reducing gas into a run coal bin by crushing and screening the mine run coal into crushed coal; b) milling the crushed coal to minus 200 meshes and above 60 percent by a coal-milling device provided by a coal feeder and carrying out drying at the same time; and c) putting the finished braise into a pulverized coal bunker after the separation of gas and powder; loading the braise into 2 or 3 coal injecting tanks sequentially; transporting the braise to a distributor mechanism positioned at the top of a melting gasification furnace of the COREX stove by using pressured gas after the processes of pressurizing fluidization and gas supplement; distributing the braise to the blowing branch pipe which is led to the oxygen tuyere of the melting gasification furnace; spraying the braise into the melting gasification furnace by a coal injection gun. The method has the advantages that the in-place digestion and utilization of powder sifted range coal of the filling bed COREX stoveis realized; and the total coal consumption of the COREX stove can be reduced by replacing part range coal; therefore, the cost of production is reduced; more optimized COREX melting reduction process and more flexible operation are realized.

Description

A method and device for preparing and injecting pulverized coal in a packed bed smelting reduction furnace technical field The invention relates to smelting reduction ironmaking technology, in particular to a method and device for preparing and injecting pulverized coal in packed bed smelting reduction furnaces such as COREX. Background technique In order to solve the problems of large investment and heavy pollution in the traditional blast furnace ironmaking method, since the 1970s, a COREX furnace ironmaking method, namely the smelting reduction ironmaking method, has been developed in the world. The ironmaking method directly uses ordinary lump coal of a certain size and is pretreated to be put into the furnace to generate heat for smelting molten iron and reducing gas. In order to make full use of the resource of fine coal produced during coal transportation, technicians in this ironmaking method are working hard to find a stable and reliable process equipment for the ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C21B13/00C22B5/10C10L5/00

Inventor 黄春进徐万仁陈玉明施国华杜海钢温大威李维国张青田广亚林金嘉周渝生王东彦郭丽

Owner BAOSTEEL ENG & TECH GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com