Integrated-shaft and three-roller corner rolling device for continuous casting billet corner rolling

A continuous casting slab and three-roll rolling technology, which is applied in the field of integrated shaft three-roll corner rolling device, can solve the problems of slow speed in the middle part, fast speed in the edge part, shear cracks, etc., achieve optimized chamfer shape and simple device manufacturing , control precise effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples, but not limited thereto.

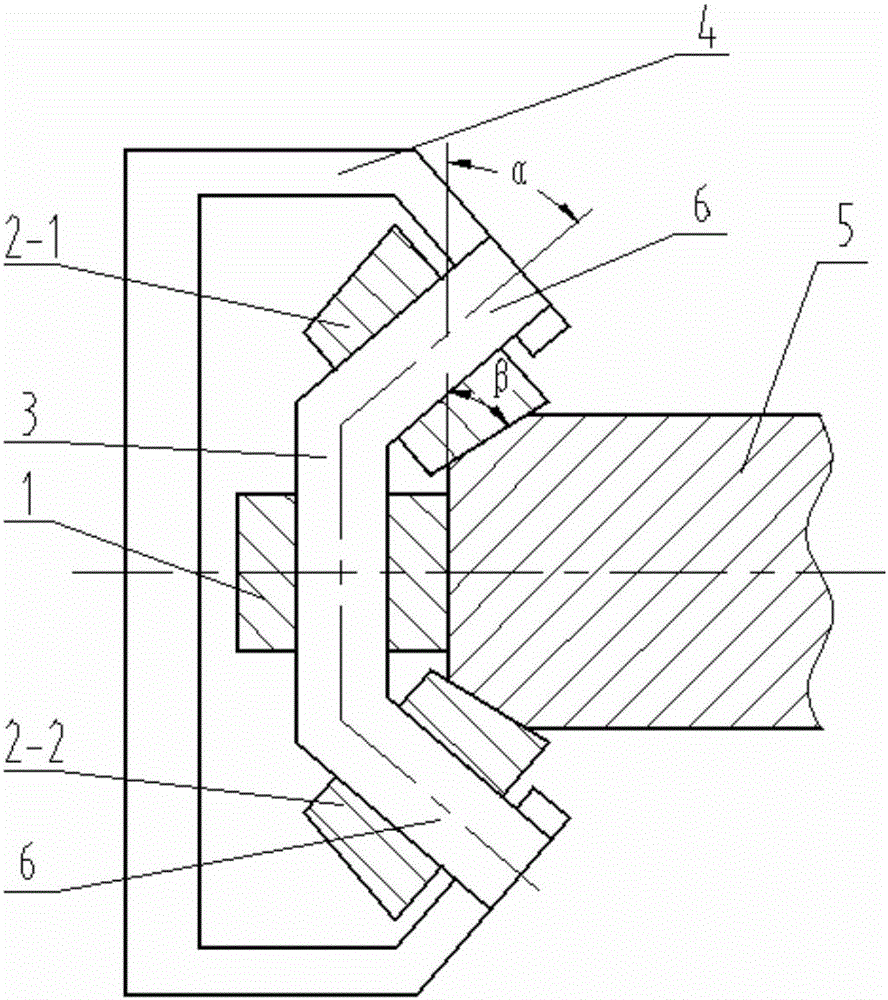

[0043] Such as figure 1 As shown, it is a schematic diagram of an integrated shaft three-roll corner rolling device for continuous casting slab corner rolling according to the present invention. The device comprises an intermediate positioning roll 1, an upper chamfering roll 2-1, a lower chamfering roll 2-2, a roll shaft and a roll support frame 4.

[0044] In order to reduce the shear rolling force, the roll shaft is designed in the shape of a broken line, wherein the roll shaft includes the middle roll shaft section 3 and the chamfered roll shaft section 6 at both ends, and the chamfered roll shaft section 6 and the middle roll The shaft section 3 is arranged at an angle of α; the middle positioning roll 1 is installed on the middle roll shaft section 3, and the upper chamfering roll 2-1 and the lower ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com