Calibration method for extracting illumination-insensitive information from visible images

A technology for sensitive information and calibration methods, applied in image analysis, image data processing, instruments, etc., can solve the problems of insufficient stability of online calibration and insensitive information of light, and achieve the effect of simple scheme

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

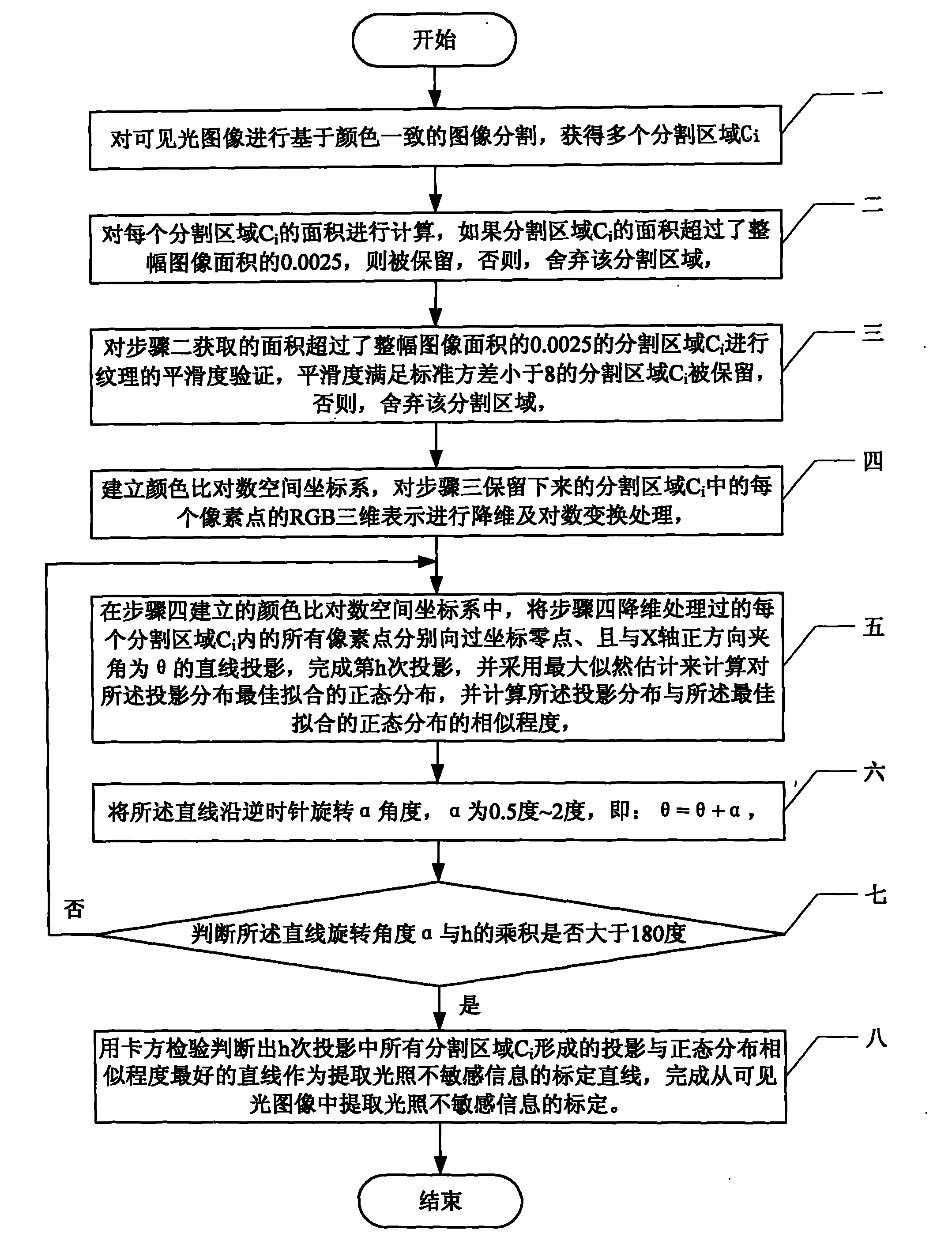

[0017] Specific implementation mode one: the following combination Figure 1 to Figure 5 Describe this embodiment, the method of this embodiment includes the following steps:

[0018] Step 1. Segment the visible light image based on consistent color to obtain multiple segmented regions C i , where, i=1, 2,..., m, m is a positive integer,

[0019] Step 2. For each segmented area C i The area is calculated if the segmented area C i If the area exceeds 0.0025 of the entire image area, it will be retained, otherwise, the segmented area will be discarded,

[0020] Step 3. For the segmented area C whose area obtained in step 2 exceeds 0.0025 of the entire image area i Verify the smoothness of the texture, and the smoothness meets the segmentation area C with a standard deviation less than 8 i is retained, otherwise, the segmented area is discarded,

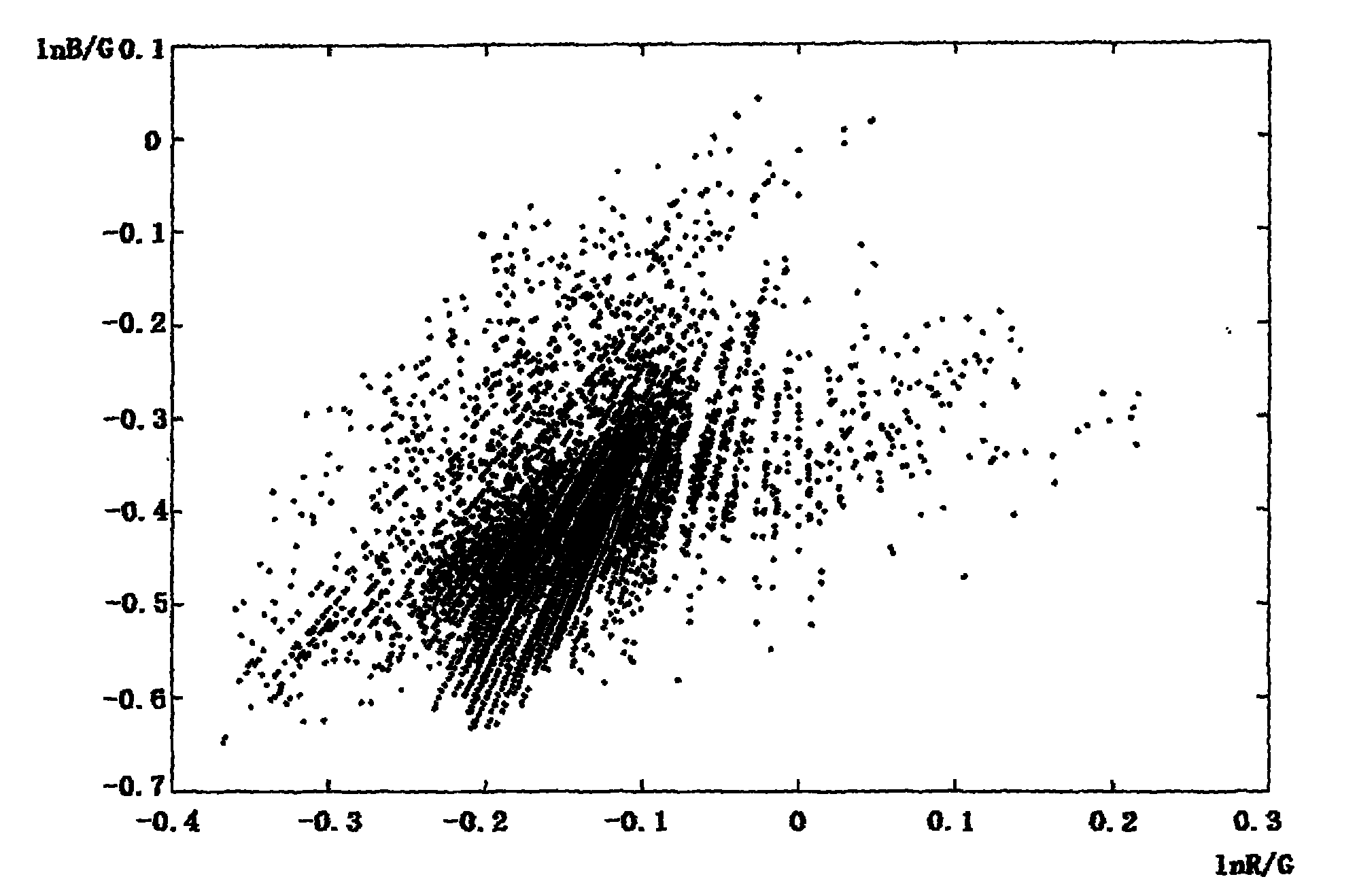

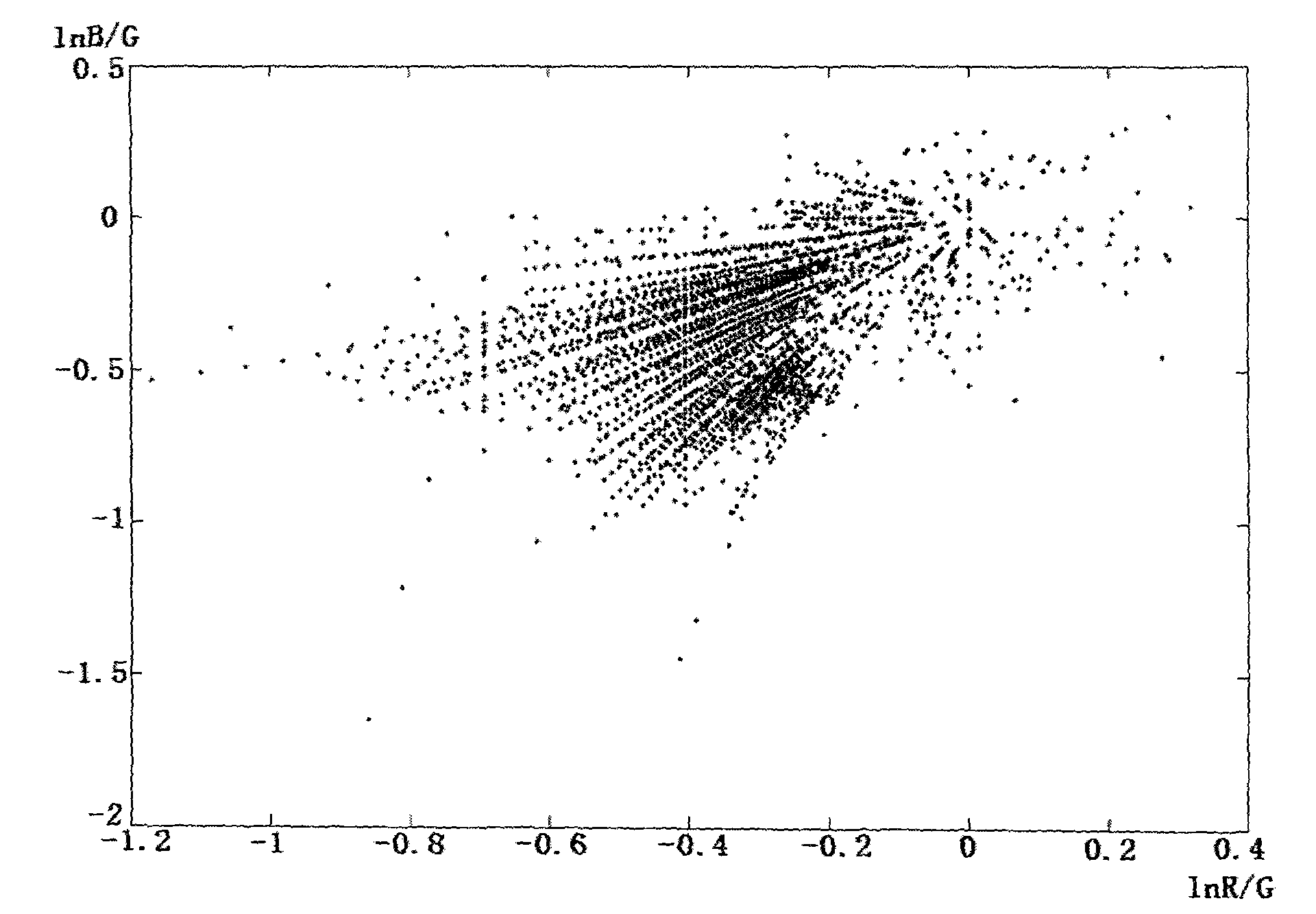

[0021] Step 4: Establish a color ratio logarithmic space coordinate system, and divide the region C retained in Step 3 i The RG...

specific Embodiment approach 2

[0048] Embodiment 2: The difference between this embodiment and Embodiment 1 is that α in step 6 is 1 degree, and the others are the same as Embodiment 1.

[0049] If each rotation is 1 degree, the number of projections h=180, a total of 180 straight lines, and finally one of them is determined as the calibration straight line.

specific Embodiment approach 3

[0050] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the criterion for judging the color consistency in step 1 is: the chromaticity value between pixels is less than a threshold T, and the others are the same as Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com