Renewing preparation method for radial tire steel wire cord layer fracture

A radial tire and steel cord technology, which is applied in the field of retreading and preparation of reclaimed tires with broken steel cord layers in radial tires, can solve the problems of tire loss of use value, waste, loss of use value, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

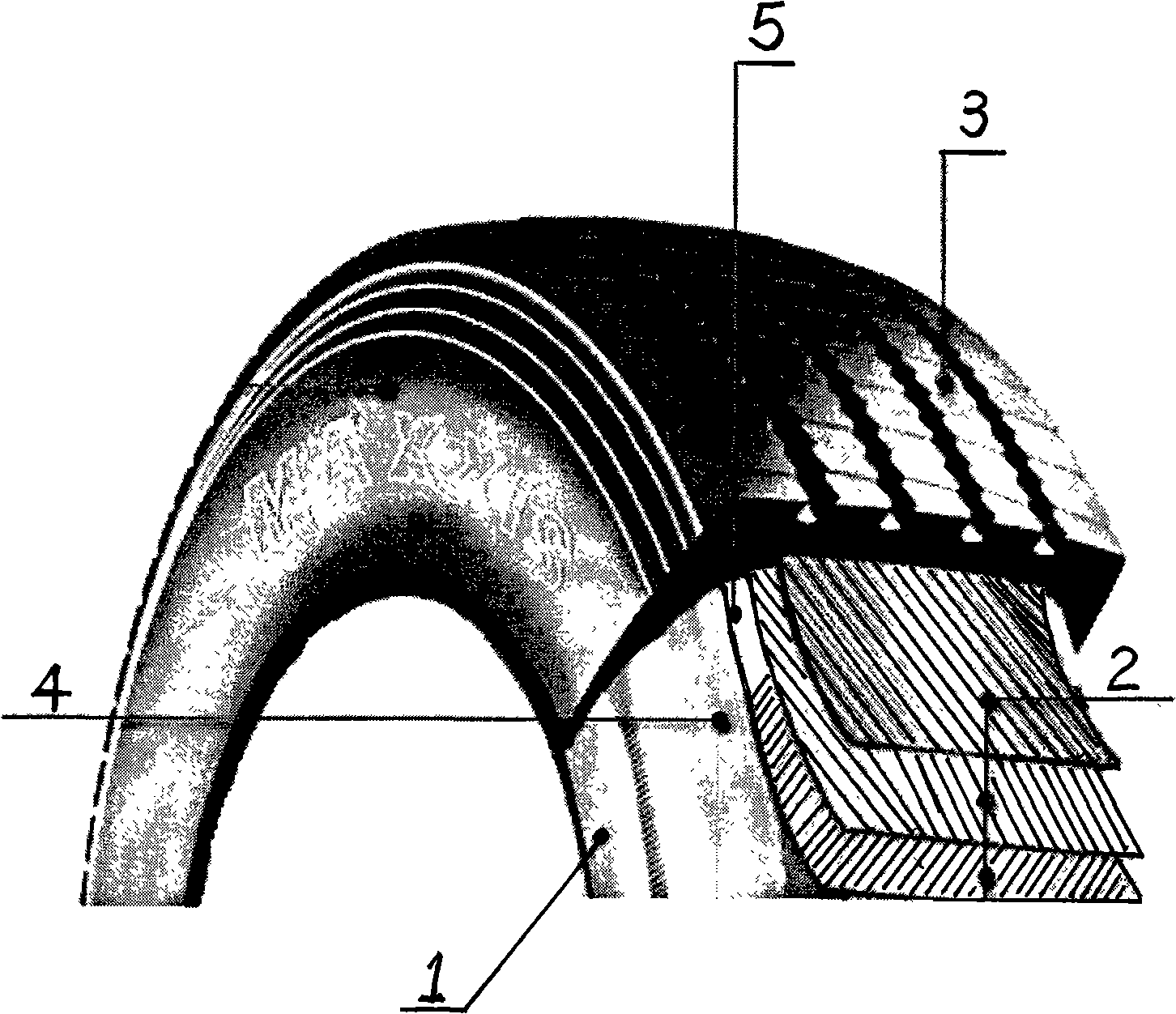

[0016] Embodiment 1, the first step, select the carcass, peel off the broken part of the carcass 1 and the steel cord layer 2 at the damaged part of the tire, peel off the damaged broken layer, remove the discarded damaged part, and expose the carcass 1 layer, That is, it is used as a joint surface for grinding treatment, and the carcass 1 is ground to a rough and fluffed pockmarked surface by a steel wire wheel for use;

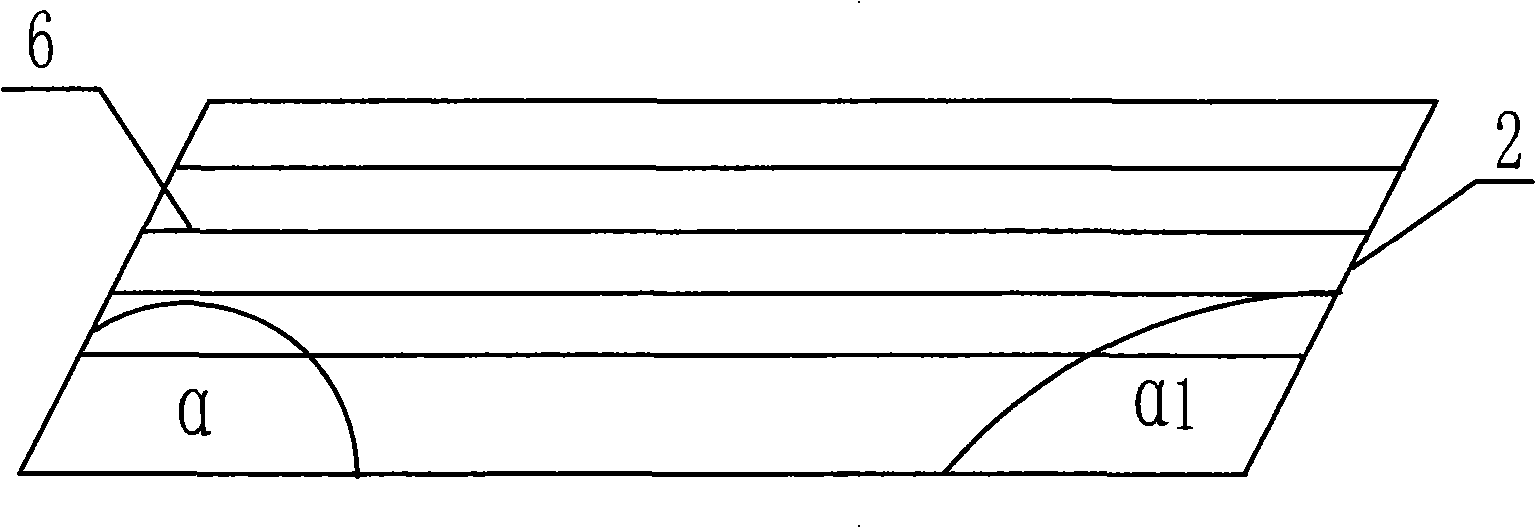

[0017] The second step is to prepare the steel cord layer 2, configure the steel cord layer 2 according to the specifications and dimensions of the new mating surface, and use the special cutting equipment to cut the steel cord layer 2 into a steel cord layer with an angle α at one end 2. α is 15°, the other end surface α1 of the steel cord layer 2 is 75°, and the angle α and α1 are butted at the beginning and the end, and the bonding of a steel cord layer 2 is completed by matching;

[0018] The third step is to reassemble, brush the carcass rubber 4 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com