Automatic gap adjusting arm of automobile brake and rotation angle control device thereof

A technology of gap adjustment and rotation angle, applied in the direction of slack adjuster, etc., can solve the problems of difficult manufacturing, many parts, heavy cost, etc., and achieve the effect of low manufacturing cost, ensuring driving safety and few parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

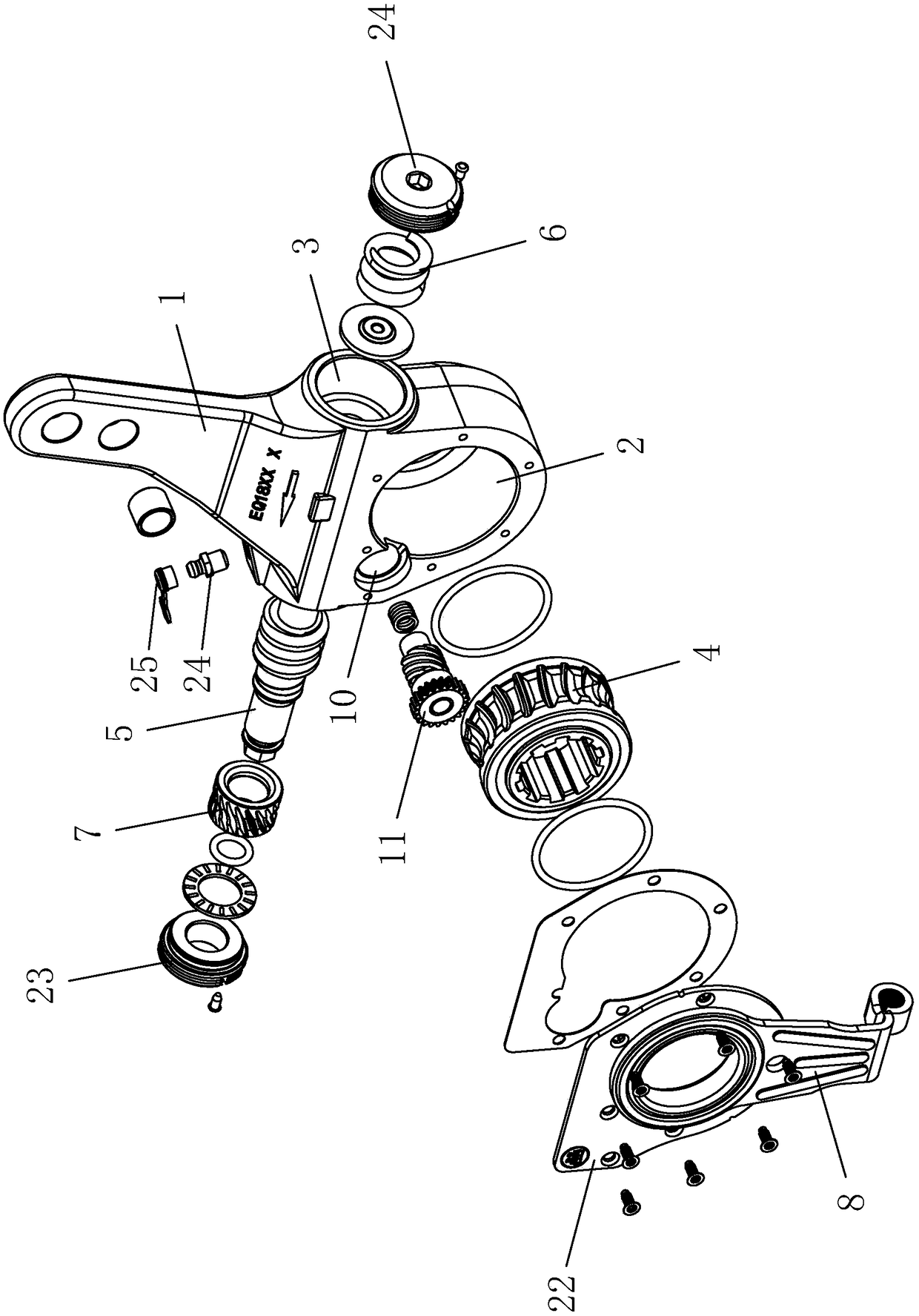

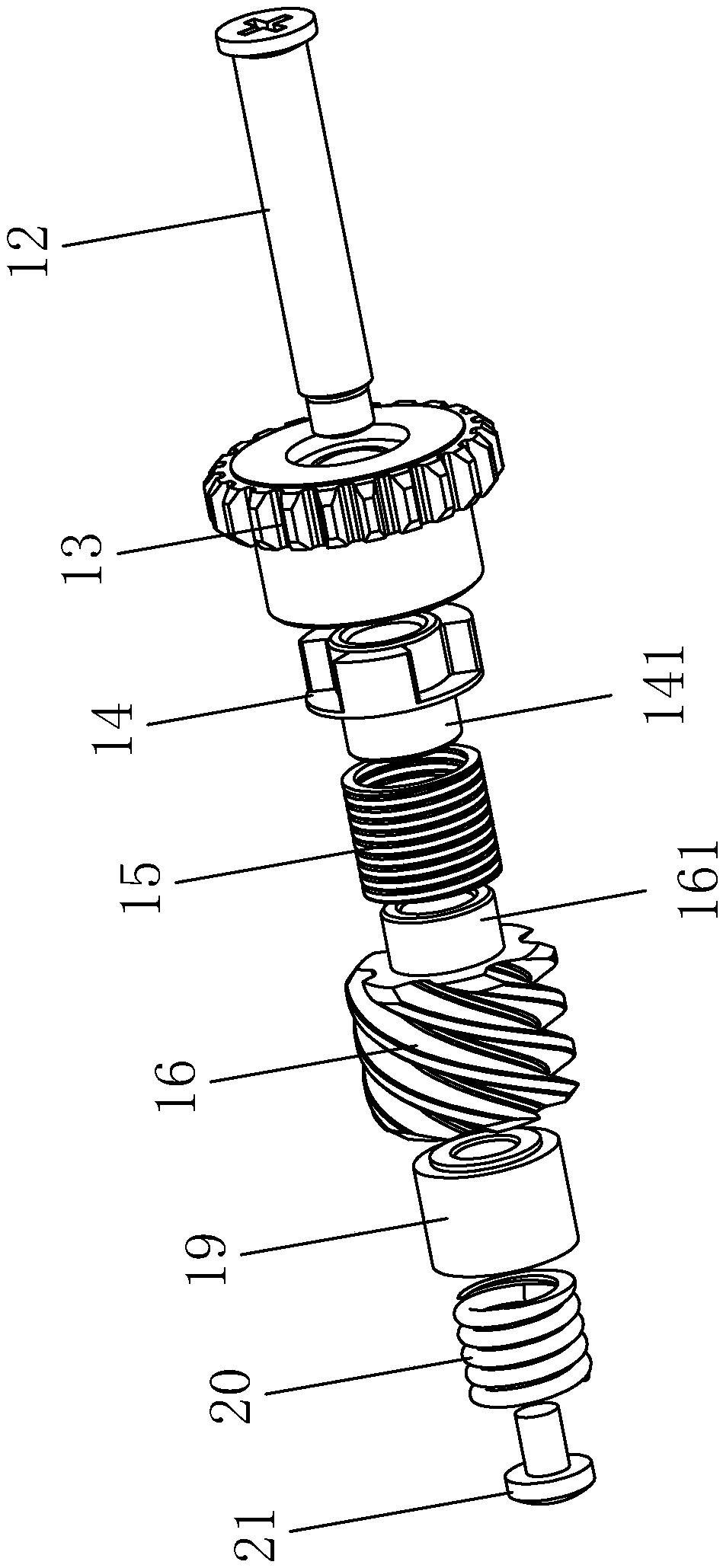

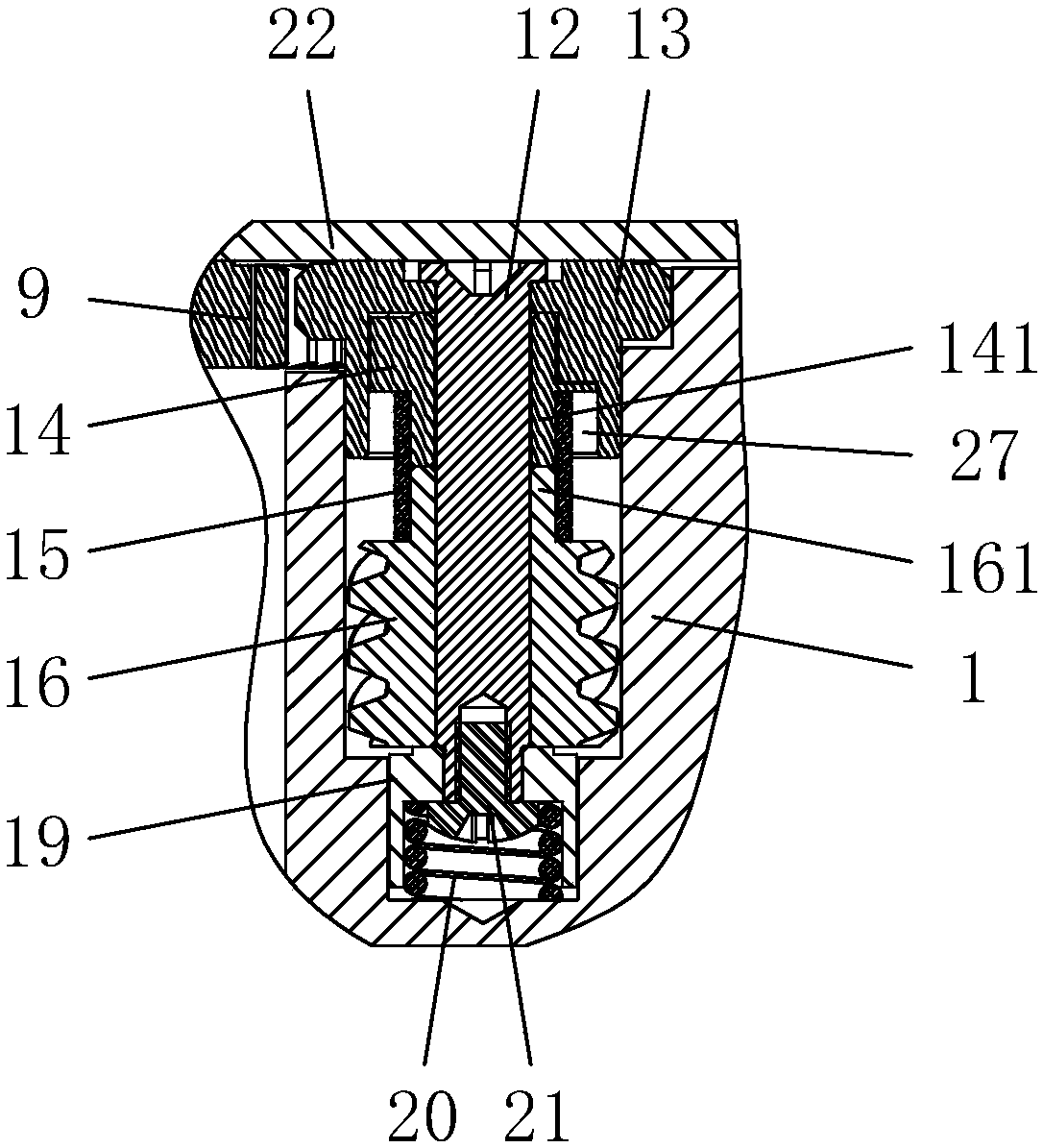

[0030] as attached figure 1 to attach Figure 13 As shown, an automatic gap adjustment arm of an automobile brake includes a housing 1, and the housing 1 is provided with a first through hole 2 and a second through hole 3 axially connected to each other, and the first through hole 2 A turbine 4 is installed inside, and a first worm 5 matching the turbine 4 is installed in the second through hole 3. A coil spring 6 is provided at one end of the first worm 5, and a clutch gear is set at the other end. 7. One end of the first through hole 2 is provided with a control disc assembly, and the control disc assembly includes a ring gear 9; the housing 1 is also provided with the first through hole 2 and the second through hole 3 connected third through holes 10, the axes of the third through holes 10 and the first through holes 2 are parallel to each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com