Seed crystal splicing method used for monocrystal-like silicone cast ingot

A single crystal silicon and seed crystal technology is applied in the field of seed crystal splicing for quasi-single crystal silicon ingots. efficiency, increase the area ratio of single crystal, and reduce the effect of dislocation defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

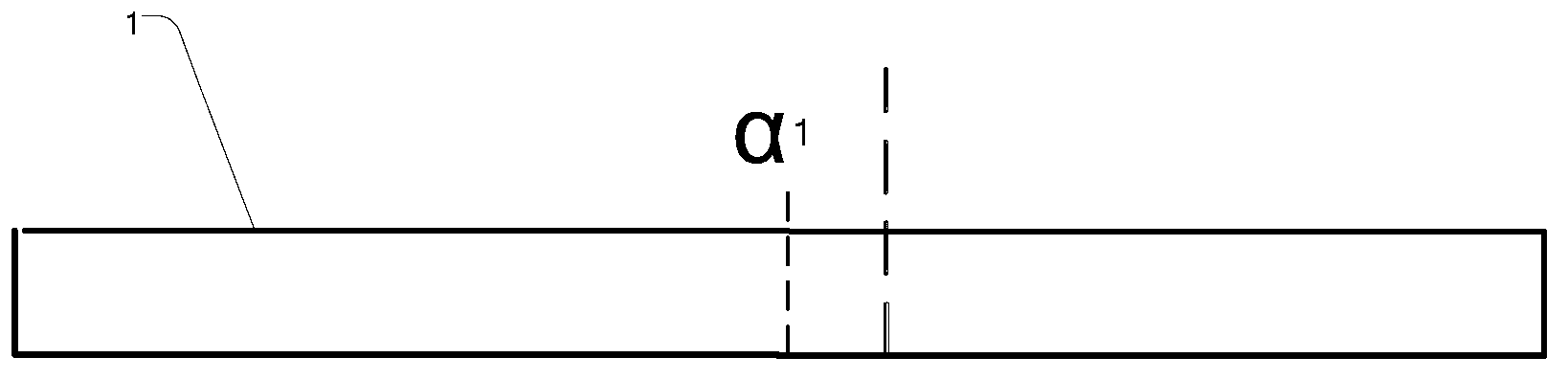

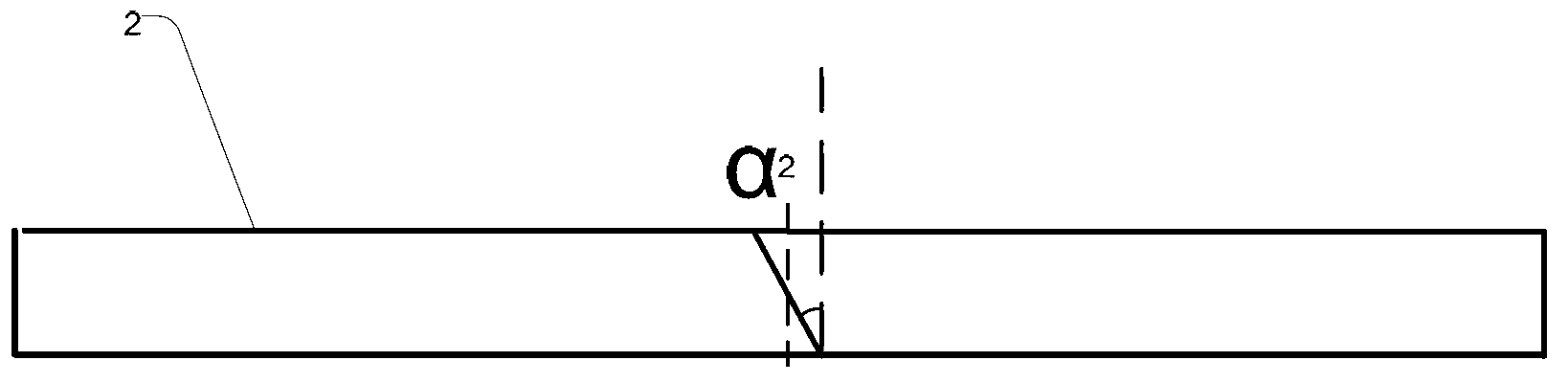

[0027] An embodiment of the present invention provides a seed splicing method for a single crystal silicon ingot, which is used for ingot casting by directional solidification. A seed crystal layer is laid on the bottom of the flat-bottomed crucible, the seed crystal layer is formed by closely arranged seed crystals, and the crystal orientation of all the seed crystals along the normal direction of the bottom plane of the flat-bottomed crucible is the crystal orientation. Specifically, the splicing surfaces of the two adjacent seed crystal layers are matched closely with each other. The seed crystal is a cuboid seed crystal, and the tangent direction of the splicing surface of every two seed crystals forms an angle α with the normal direction of the bottom plane of the flat-bottomed crucible, 0°<α<90°. Silicon material is placed on top of the seed layer. Through temperature control in the melting stage, after the silicon material is completely melted into silicon liquid, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com