New charging method of schreyerite smelting blast furnace

A new method and technology of vanadium-titanium ore, applied in the field of vanadium-titanium smelting, can solve the problems of hearth elephant foot erosion, insufficient development of central gas flow, poor central gas flow, etc., to achieve technological progress, reduce production costs, ensure The effect of furnace temperature stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] The selected blast furnace volume is 430m 3 ;

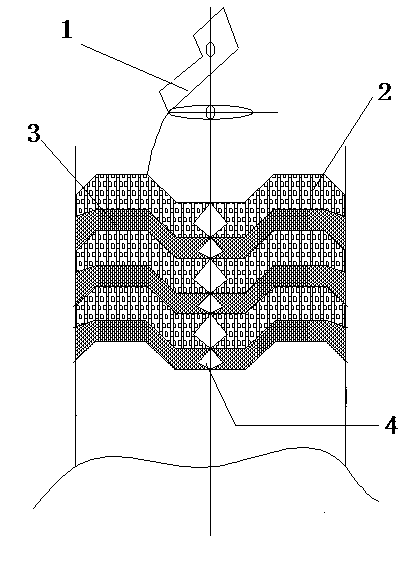

[0020] The ore and coke double-ring distribution method is adopted, that is, two angles of distribution, and the mode of positive packaging, that is, each batch of materials is first added with ore, then with coke, and then with the center coke:

[0021] Among them, ore is P, coke is K, n is the number of α angle rotations, 33 and 27 are α angles respectively; 3 and 4 are respectively the rotation numbers of α angles; the downward arrow indicates the node of the distributor after the material is placed. Flow valve is closed.

[0022] 1) Control the number of rotations of the chute to be 11 when the two cars of ore are added. First, rotate 4 times according to the angle of α=33°β to add, and then rotate the remaining ore 7 times according to the angle of α=27°β to add. After the completion, add two cars of coke, control the number of rotations of the chute when the two cars of coke are added to be 9 circles, and rotate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com