Compact large-framework-angle conformal optical system

An optical system and frame angle technology, applied in the field of optical systems, can solve problems such as the inability to achieve good imaging of a large target field of view without vignetting, limit the development of conformal optics technology, and cannot correct conformal window astigmatism and coma. Achieve the effect of simple structure, wide range of uses and easy installation and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

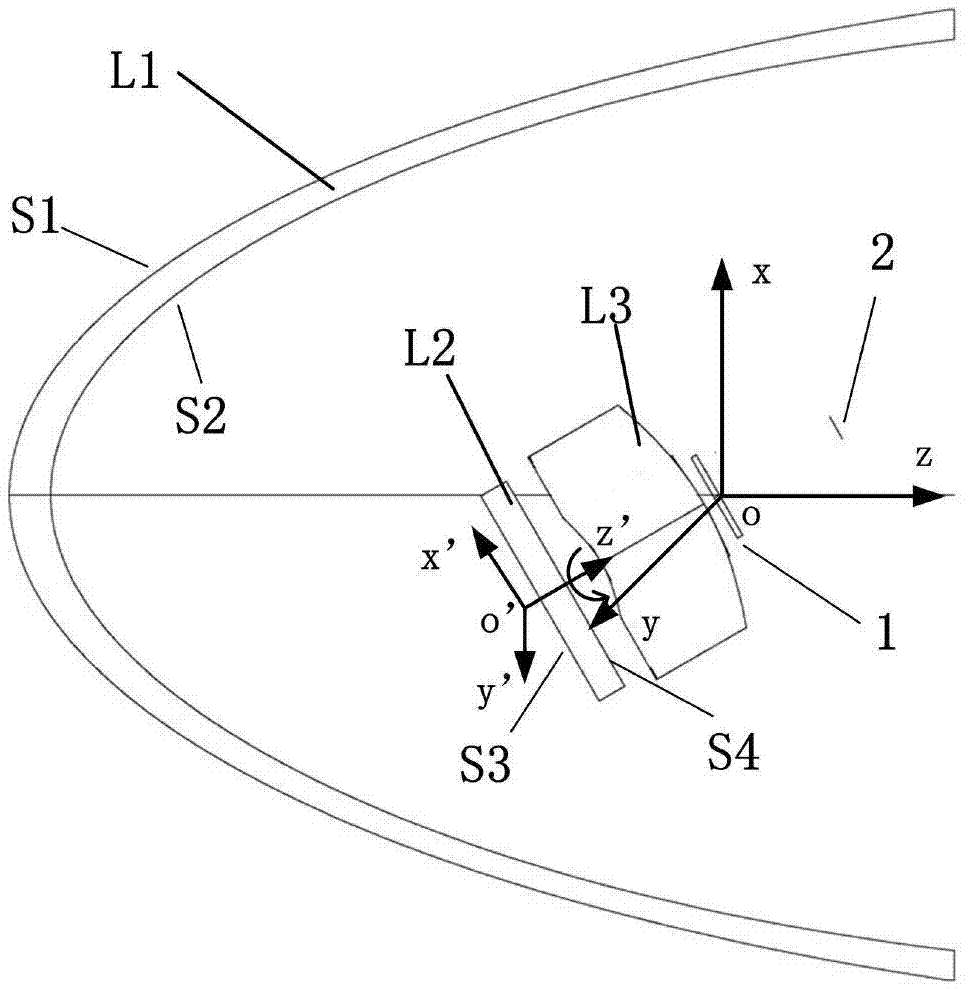

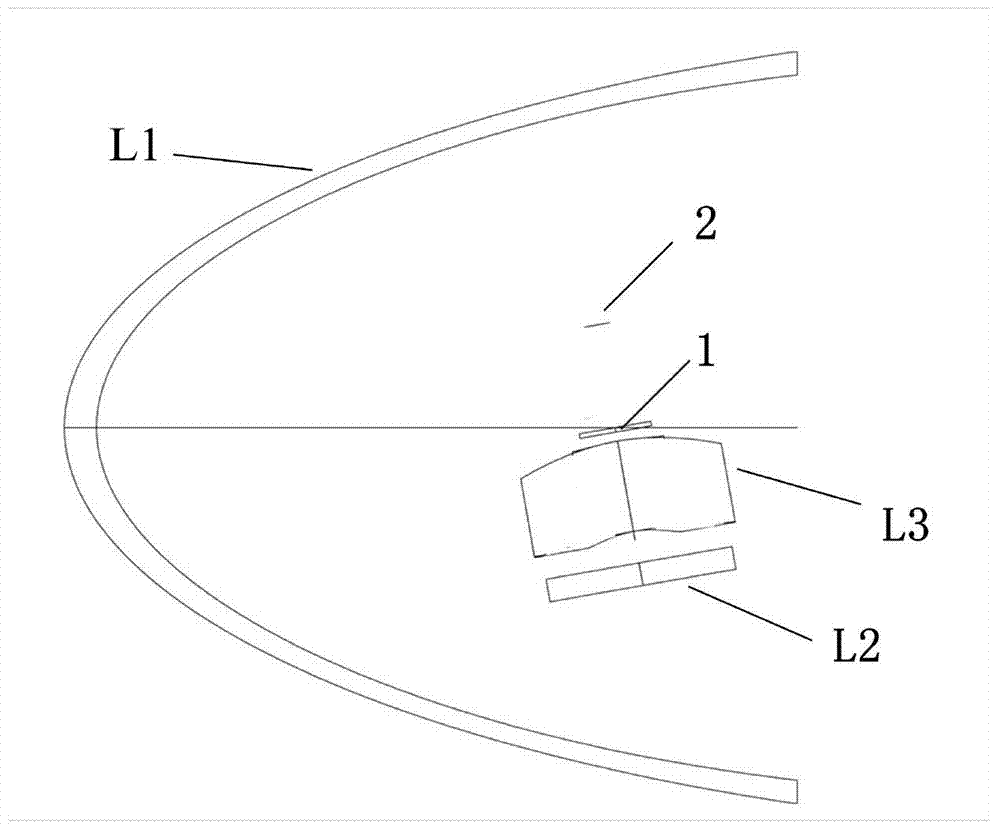

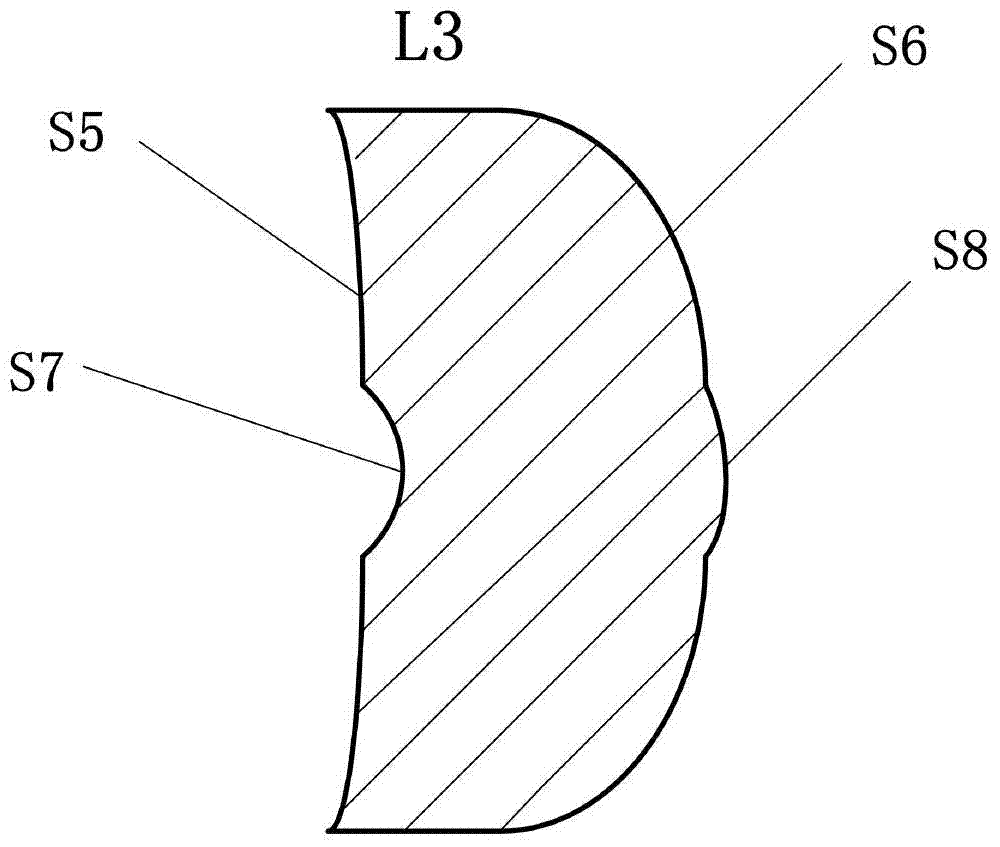

[0026] like figure 1 and figure 2 As shown, the compact large frame angle conformal optical system of the present invention includes a fairing L1, a cylindrical correction lens L2, an imaging lens group L3 and a diaphragm 1, and the cylindrical correction lens L2 is located behind the conformal optical window for The light aberration of the dome is corrected, the imaging lens group L3 is located behind the cylindrical correction lens L2, and the diaphragm 1 is located behind the imaging lens group L3. The cylindrical correction lens L2, the imaging lens group L3, the diaphragm 1 and the detector 2 as a whole can rotate around the x-axis and the y-axis around a point o on the optical axis of the fairing L1, and the angle with the z-axis is α, at the same time, the cylindrical correction lens L2 can also rotate around its own optical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com