Blast furnace bellless furnace top distributor

A technology of distributing device and bellless, applied in blast furnace, blast furnace details, blast furnace parts and other directions, can solve the problems of shortening the service life of working parts, no water cooling, shortening service life, etc., to save manufacturing cost and reduce working temperature , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

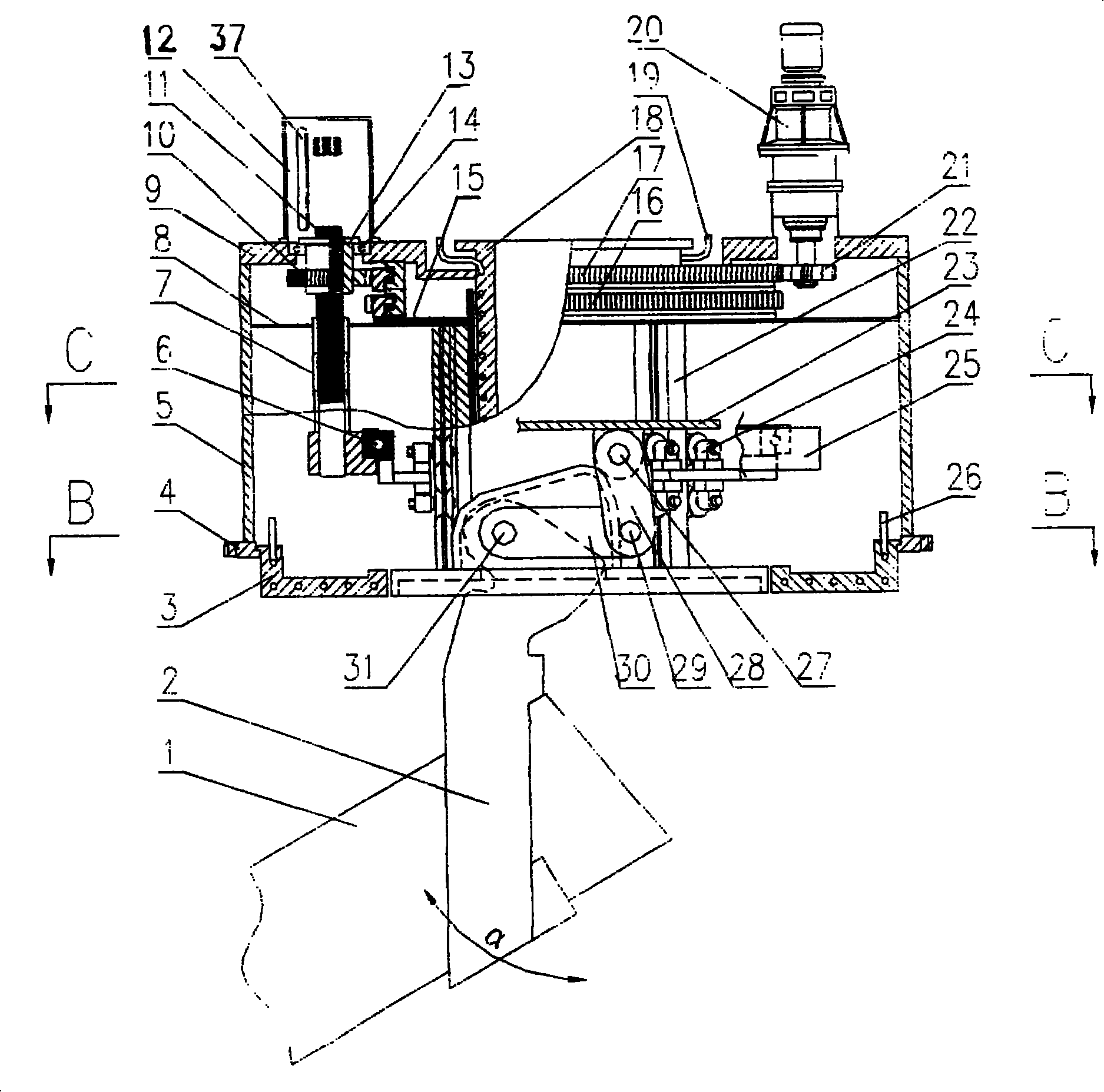

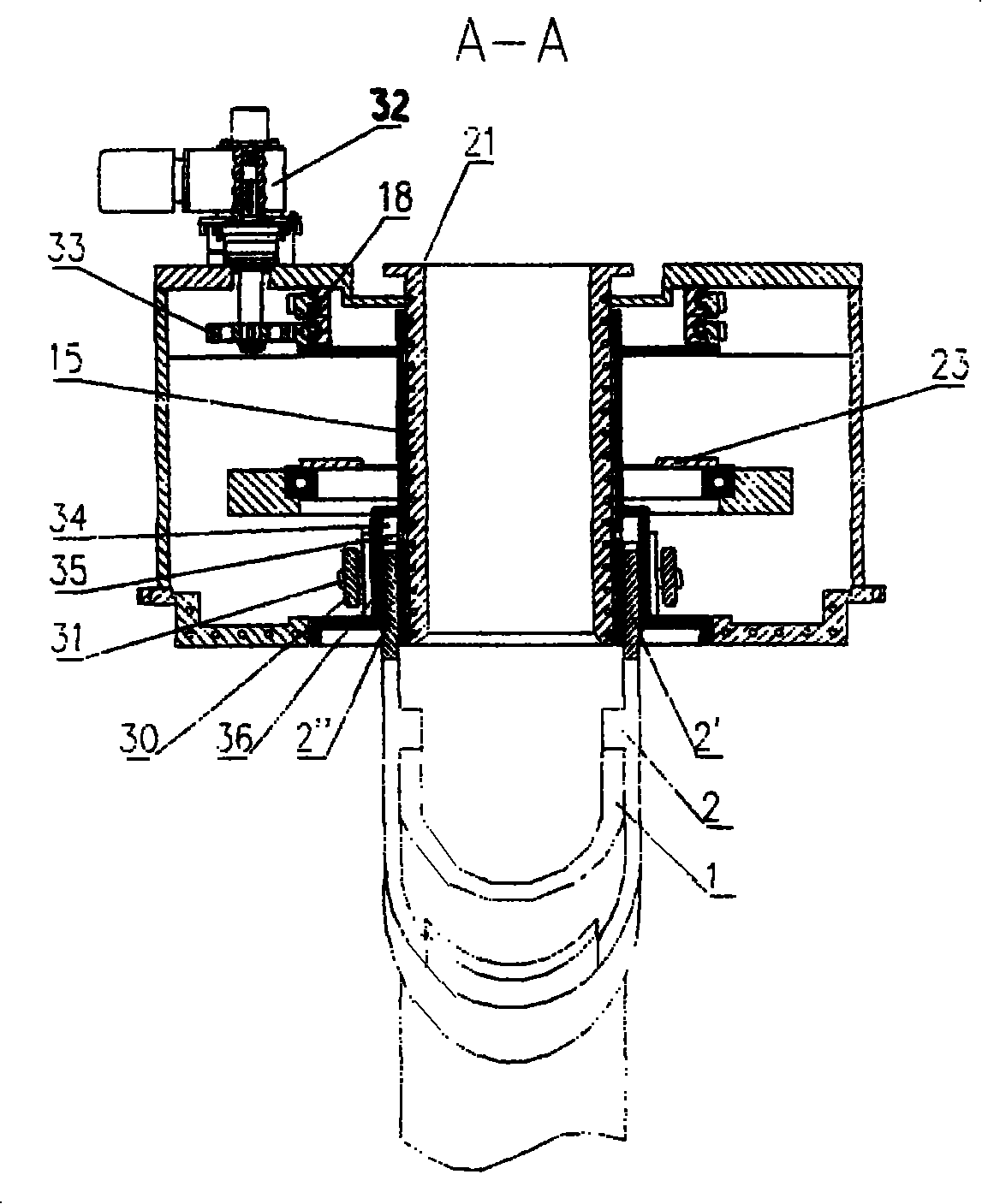

[0027] The present invention is described in detail below in conjunction with accompanying drawing:

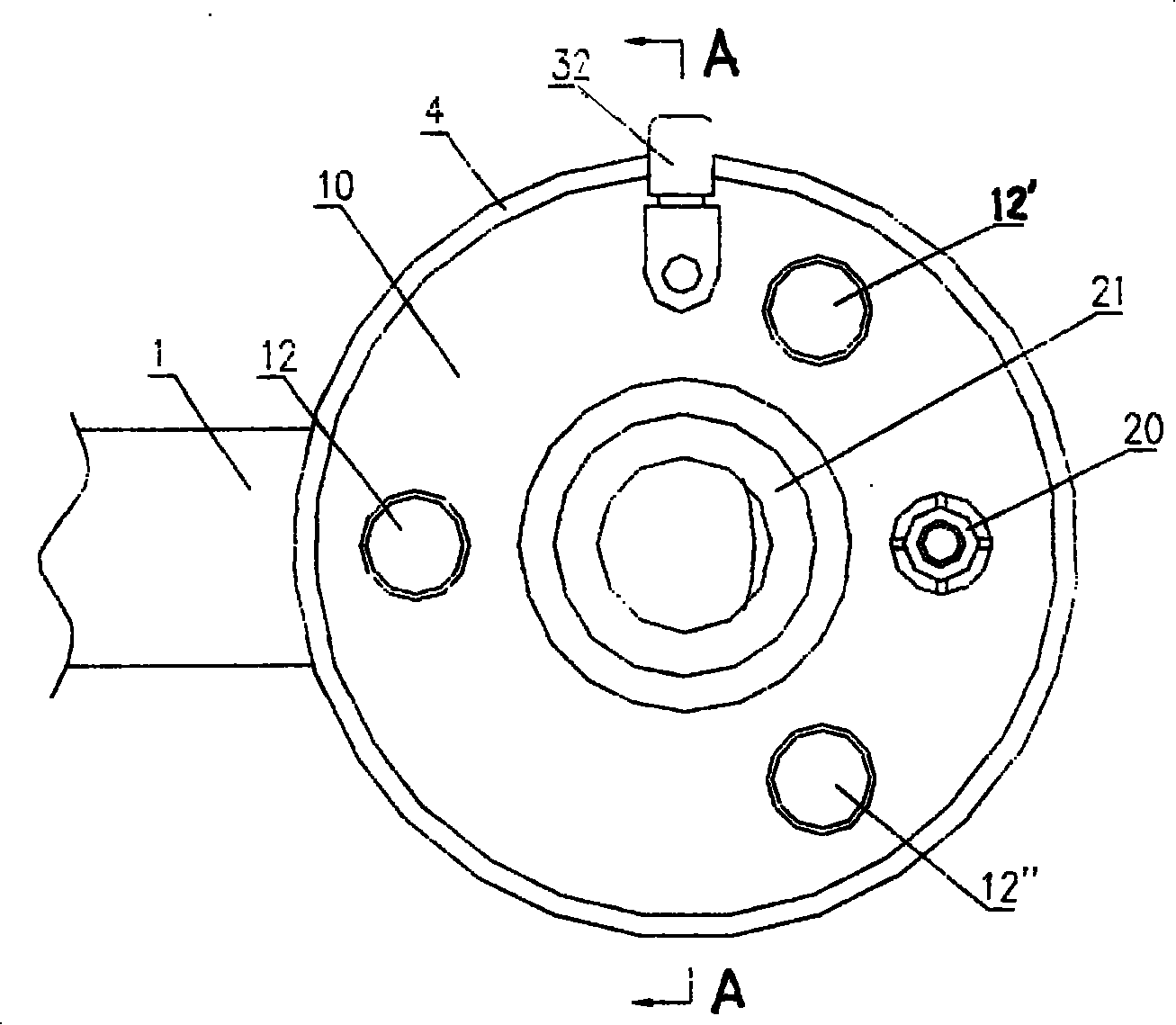

[0028] Such as figure 2As shown, above the device box cover 9, the water-cooled throat pipe 18 is vertically hoisted in the center, and two motors 20, 32 and three sealing covers 12, 12', 12 "are installed around the outer seat of the water-cooled throat pipe 18 ". Among them: a The motor 32 is used for the rotary drive of the chute, that is, the rotary motor; the other motor 20 is used for the tilting drive of the chute α angle, that is, the tilting motor. The three sealing covers 12, 12', 12" are distributed at 120° with the water-cooled throat 18 on the circumference of the common center. Such as figure 1 As shown, in the three sealing covers 12, 12', 12", there is a small slewing bearing 14 respectively installed concentrically with it, their outer rings are fixed with the box cover 9, and their inner rings are respectively connected with a ball screw pair The upper en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com