Method for quantitatively measuring remaining austenite in steel by X-ray diffraction polar diagram data

A technique for the quantitative determination of retained austenite for applications such as material analysis using radiation diffraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

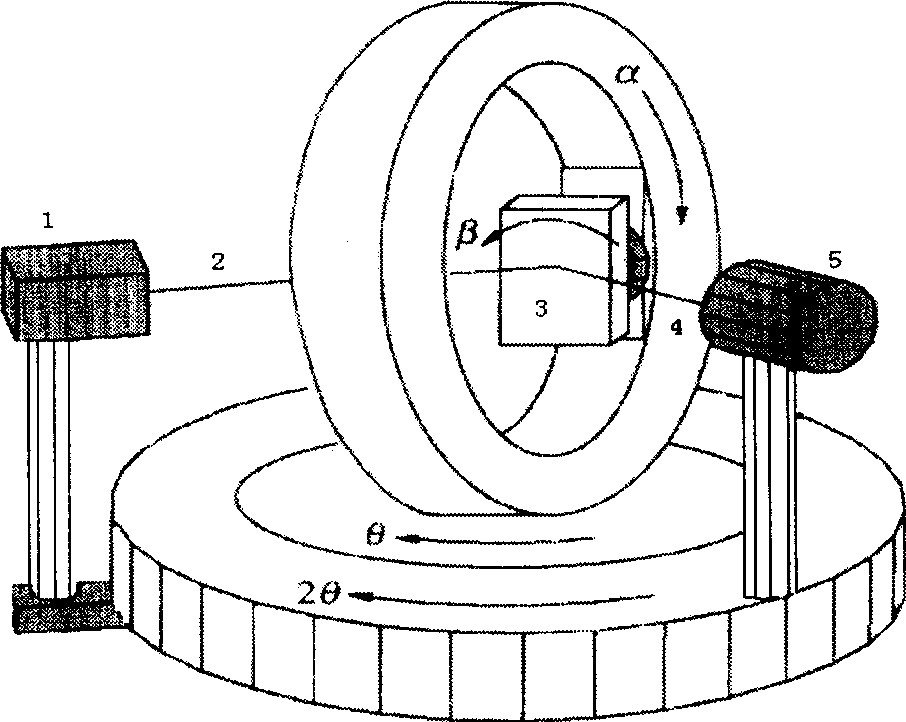

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0020] The feature of the method adopted in the present invention is that X-ray diffraction analysis technology is combined with texture attachment, and its basic principle is as follows:

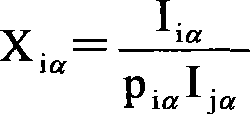

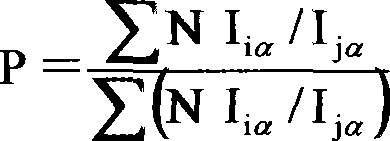

[0021] There is a piece of iron and steel material to be tested i, which contains two phases of austenite (γ phase) and martensite (α phase) (or ferrite), and at the same time there is a The physical state and chemical composition of the pure α phase (or pure ferrite) standard sample j with the same or similar chemical composition, and there is no texture in the standard sample, then the volume percentage of α phase in sample i is X iα There is the following relationship between the X-ray diffraction intensity I of its (hk1) crystal plane:

[0022] I iα I jα = ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com