Grain-oriented electrical steel sheet and method for manufacturing same

A technology of electromagnetic steel plate and manufacturing method, which is applied in the direction of circuits, magnetic objects, magnetic materials, etc., can solve the problems of the limit of impurities, and achieve the effect of excellent iron loss reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

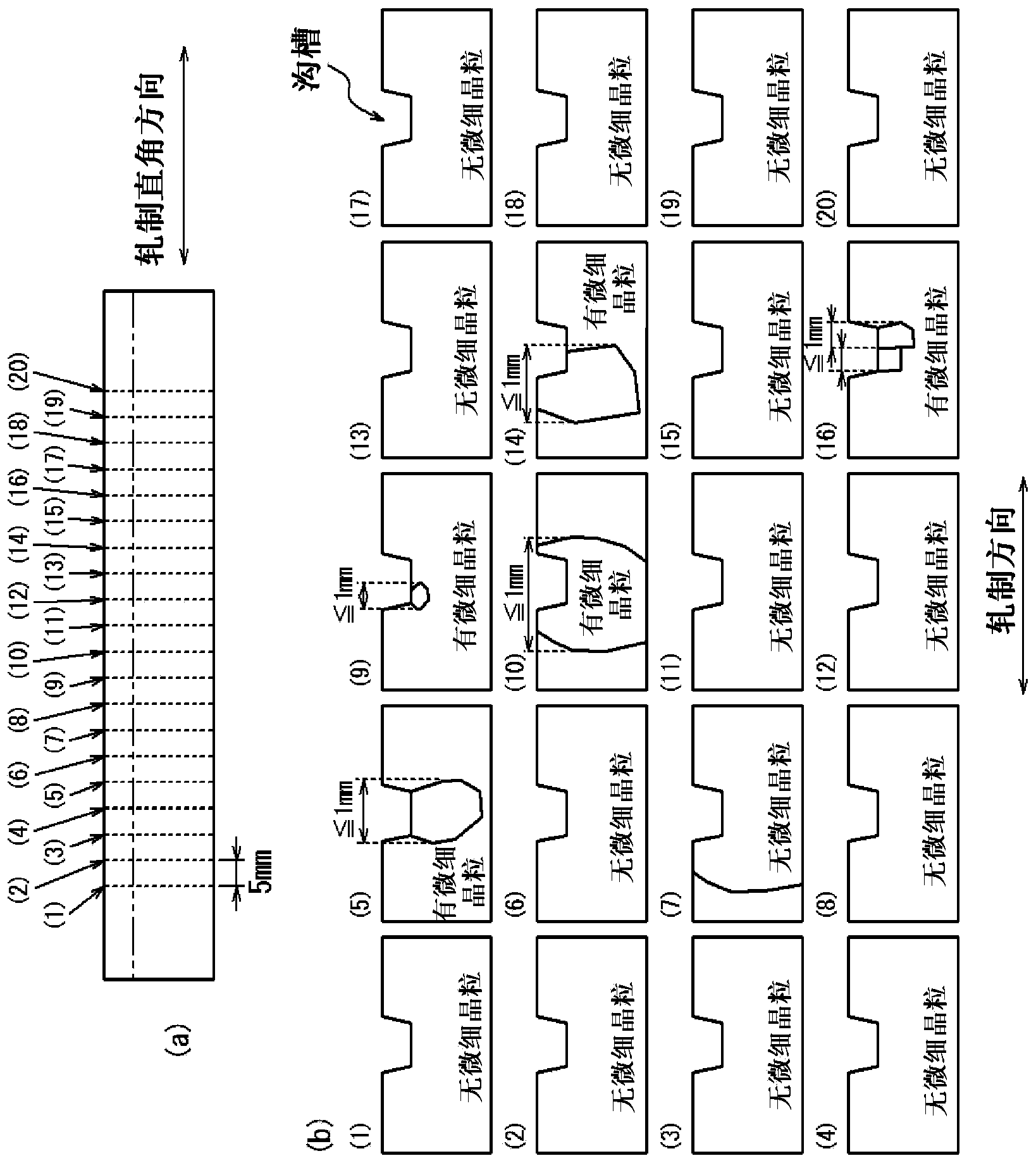

Embodiment 1

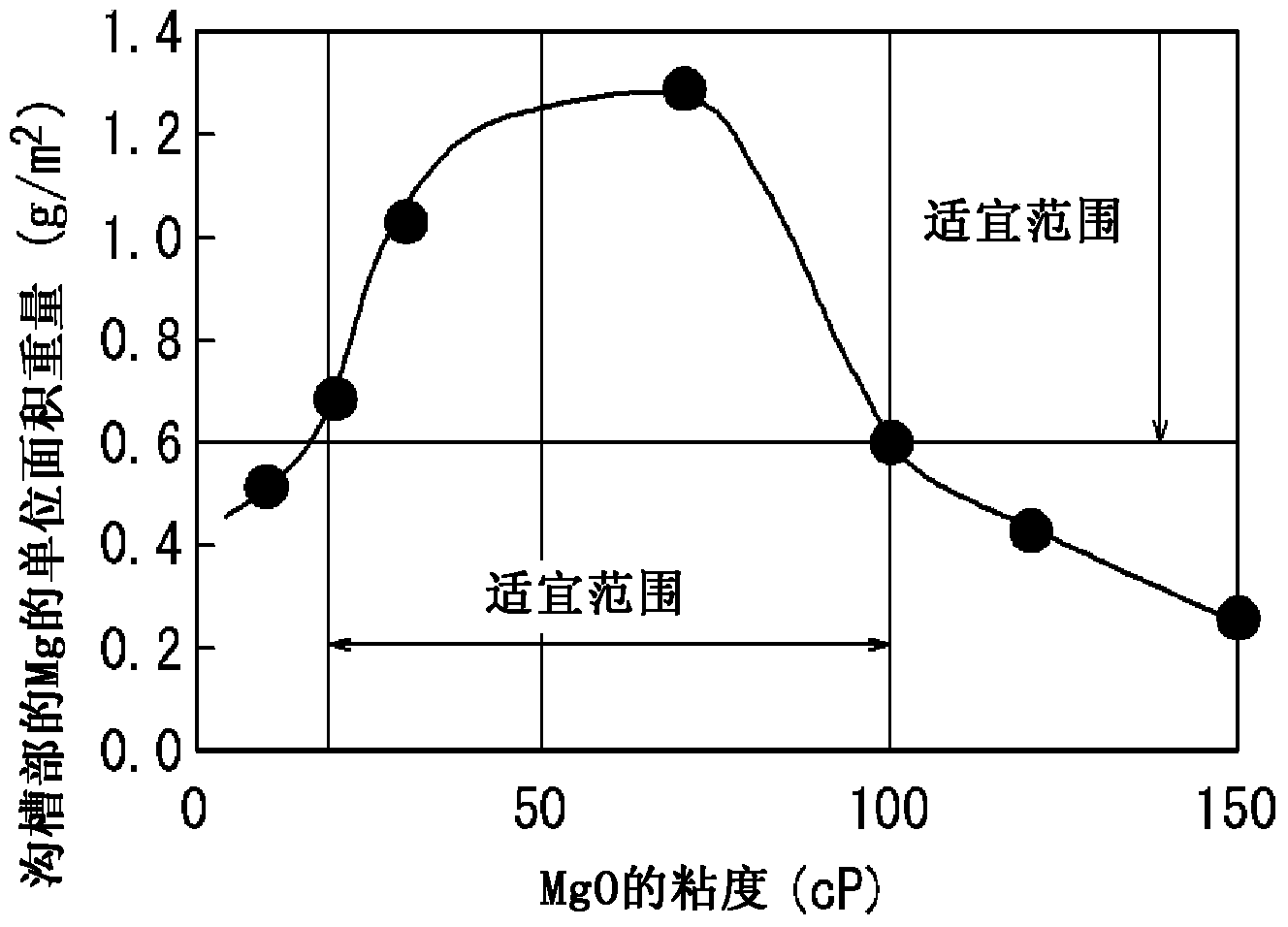

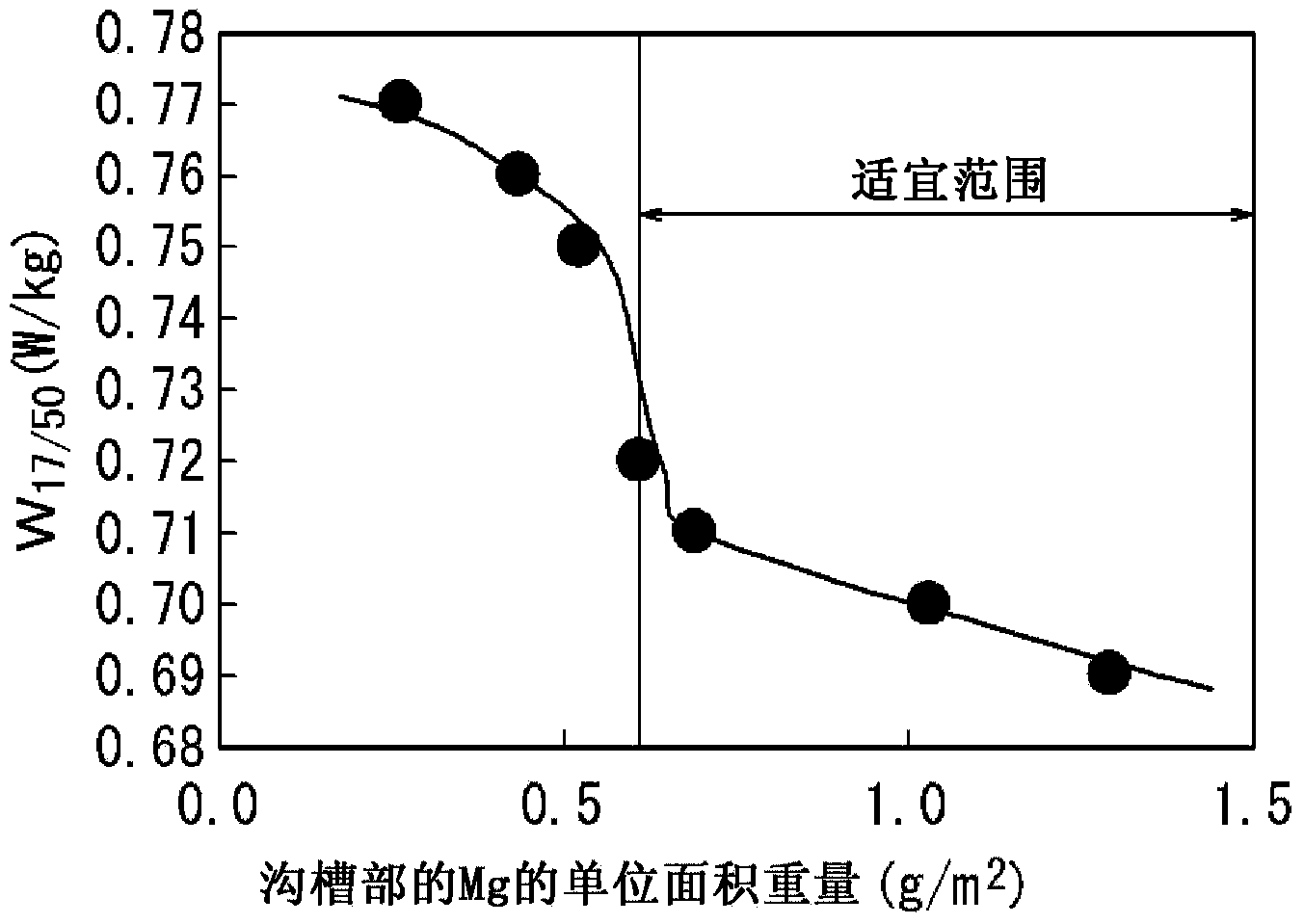

[0103] Containing C: 0.06%, Si: 3.3%, Mn: 0.08%, S: 0.023%, Al: 0.03%, N: 0.007%, Cu: 0.2% and Sb: 0.02%, and the balance is Fe and unavoidable The slab with impurities was heated at 1430°C for 30 minutes, then hot-rolled to form a hot-rolled sheet with a thickness of 2.2mm, and then annealed at 1000°C for 1 minute, and then cold-rolled until the thickness of the sheet: 1.5mm. Rolling and intermediate annealing at 1100° C. for 2 minutes, and then cold rolling to a final plate thickness of 0.23 mm. Next, linear grooves are formed by electrolytic etching or pressing with protruding rolls. Thereafter, decarburization annealing was performed at 840° C. for 2 minutes, and 10% by mass of TiO was contained in MgO: 90% by mass having a viscosity (30 minutes after mixing with water) and physical properties shown in Table 1. 2 The mixed powder was mixed with water (solid content ratio: 15% by mass), and stirred for 30 minutes to form a slurry, and an annealing separator with the viscos...

Embodiment 2

[0112] After heating the billet containing the components shown in Table 2-1 and Table 2-2 at 1430°C for 30 minutes, it was hot-rolled to form a hot-rolled sheet with a thickness of 2.2mm, and annealed at 1000°C for 1 minute. Then implement cold rolling up to plate thickness: 1.5mm, and further implement intermediate annealing at 1100°C for 2 minutes. According to the cold rolling conditions shown in Table 3 (the maximum temperature on the input and output sides is 170°C or less. The number of passes is two. The maximum temperature of the input and output side is 200°C or more, and the number of passes is three times) to make a final plate thickness of 0.23 mm, and form linear grooves by electrolytic etching.

[0113] Next, after performing decarburization annealing at 840° C. for 2 minutes, MgO (viscosity (after 30 minutes after mixing with water) is 40 cP) as the main component (93% by mass) and 6% by mass of TiO 2 , 1% by mass SrSO 4 The annealing separating agent and wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com