Strong-inhibition high-blocking-performance double-protection drilling fluid, preparation method thereof and drilling composition

A strong suppression and drilling fluid technology, applied in the field of drilling fluid, can solve the problems of poor suppression and poor plugging effect, and achieve the effects of low cost, improved drilling efficiency and improved flow pattern

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

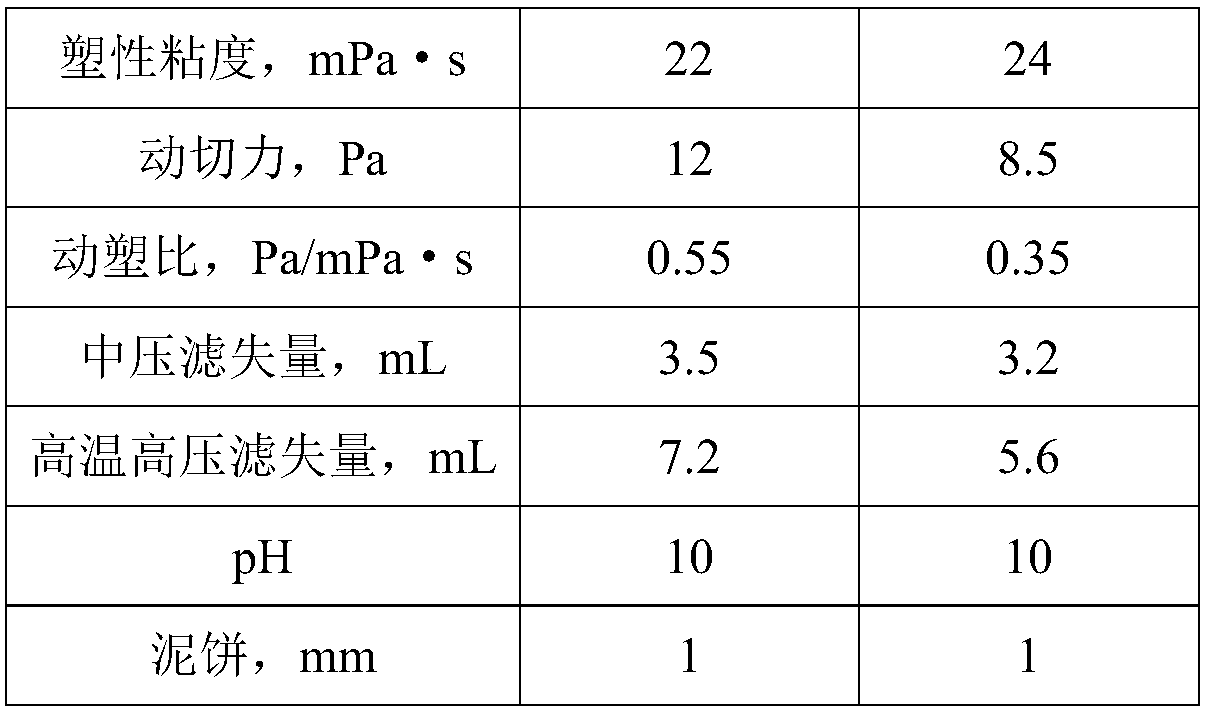

Embodiment 1

[0033] The strong-inhibition, high-plugging and dual-protection drilling fluid of this embodiment is composed of water and a drilling composition, and the specific parts by weight are: 100 parts of water, 0.15 parts of soda ash, 3 parts of bentonite, 0.5 parts of polyacrylamide potassium salt, polyacrylamide 0.4 parts of anionic cellulose, 2 parts of pregelatinized starch, 2 parts of emulsified paraffin, 3 parts of plugging agent, 0.05 parts of xanthan gum, 0.2 parts of sodium hydroxide, and 2 parts of cuttings. Cuttings are made of mudstone cuttings encountered in the same layer drilled by adjacent wells, dried at 120°C and crushed, with a particle size of 80-100 mesh.

[0034] The preparation method of the strong inhibition and high plugging double protection type drilling fluid in this embodiment adopts the following steps:

[0035] 1) Take 1000g of distilled water, add 1.5g of soda ash and 30g of sodium bentonite in sequence, stir at 400r / min for 10h, seal it, and let it sta...

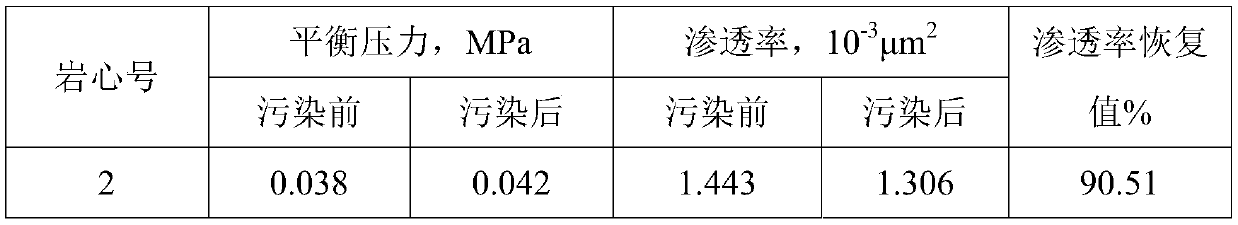

Embodiment 2

[0038] The strong inhibition and high plugging dual protection drilling fluid of this embodiment is composed of water and drilling composition, and the specific parts by weight are: 100 parts of water, 0.15 parts of soda ash, 3 parts of bentonite, 0.4 parts of polyacrylamide potassium salt, polyacrylamide 0.3 parts of anionic cellulose, 1.5 parts of pregelatinized starch, 1.5 parts of emulsified paraffin, 2 parts of plugging agent, 0.04 parts of xanthan gum, 0.2 parts of sodium hydroxide, 2 parts of superfine calcium carbonate, and 1.5 parts of cuttings. Cuttings are made of mudstone cuttings encountered in the same layer drilled by adjacent wells, dried at 120°C and crushed, with a particle size of 80-100 mesh.

[0039] The preparation method of the strong inhibition and high plugging double protection type drilling fluid in this embodiment adopts the following steps:

[0040] 1) Take 1000g of distilled water, add 1.5g of soda ash and 30g of sodium bentonite in sequence, stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com