Compact light weight autothermal reformer assembly

a technology of autothermal fuel and reformer, which is applied in the direction of gas-gas reaction process, separation process, physical/chemical process catalyst, etc., can solve the problem of more difficult reform of fuel to be processed, achieve faster start-up of reformer, improve fuel conversion rate, and reduce the ignition temperature of fuel gas fraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

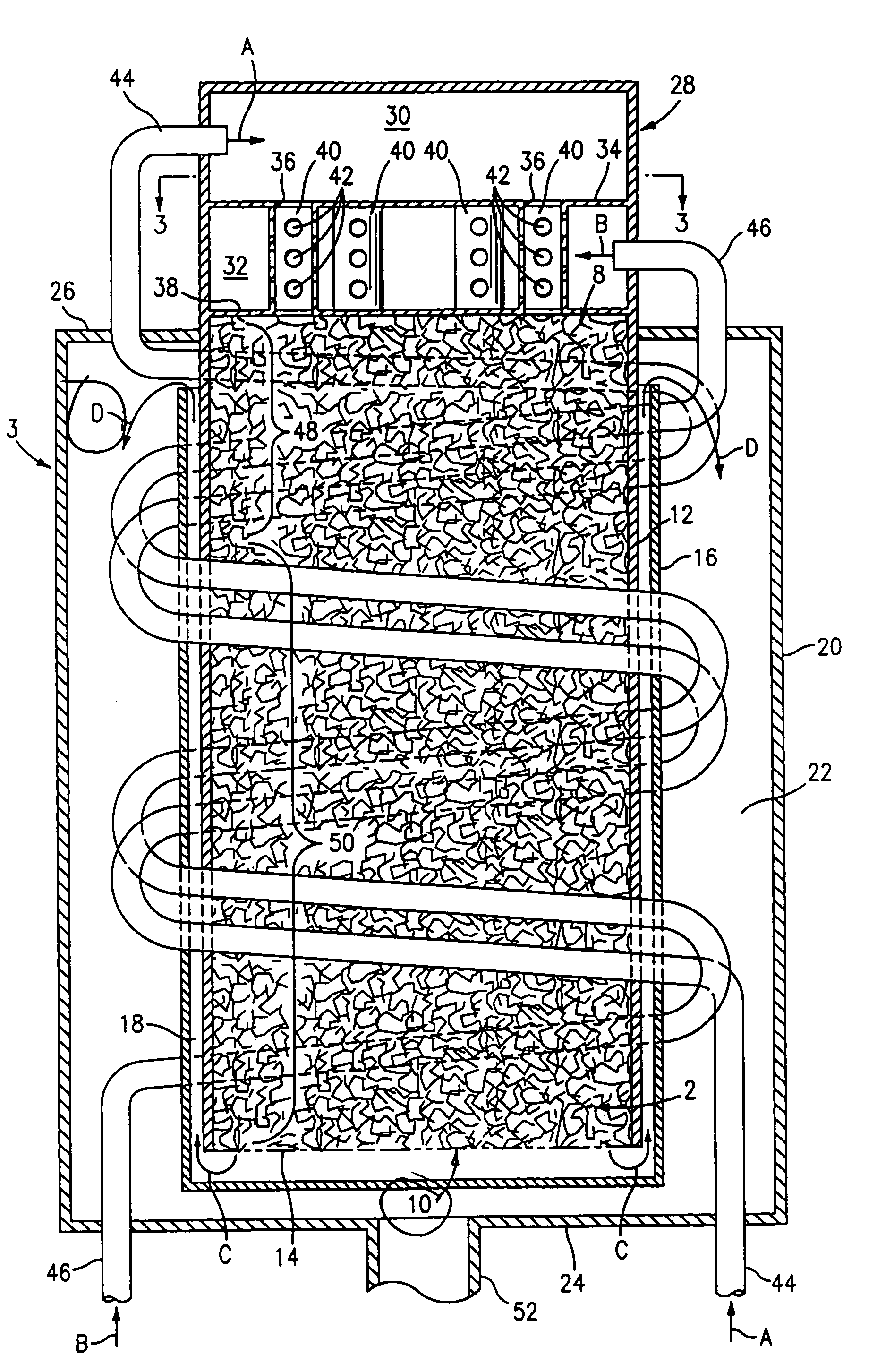

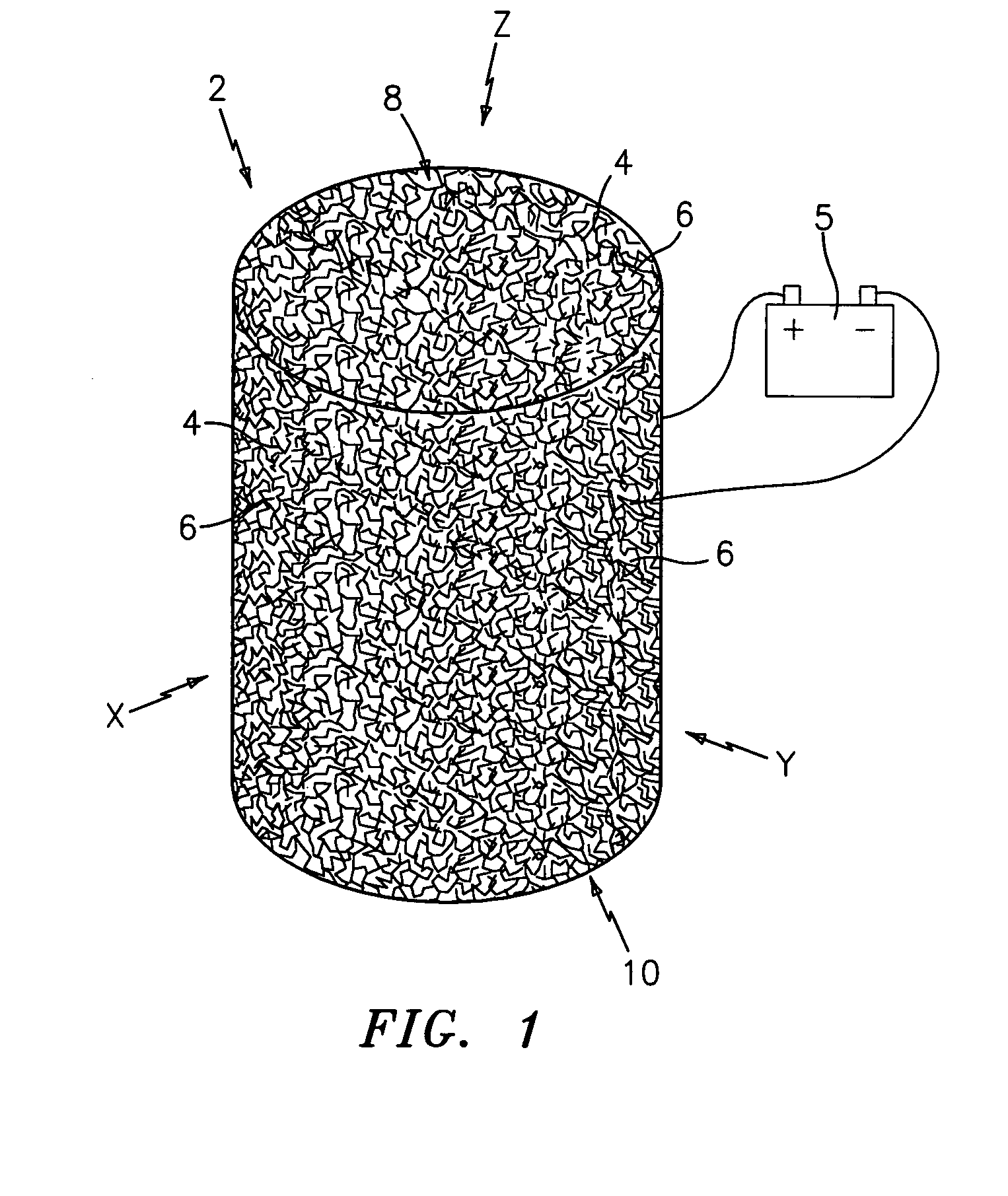

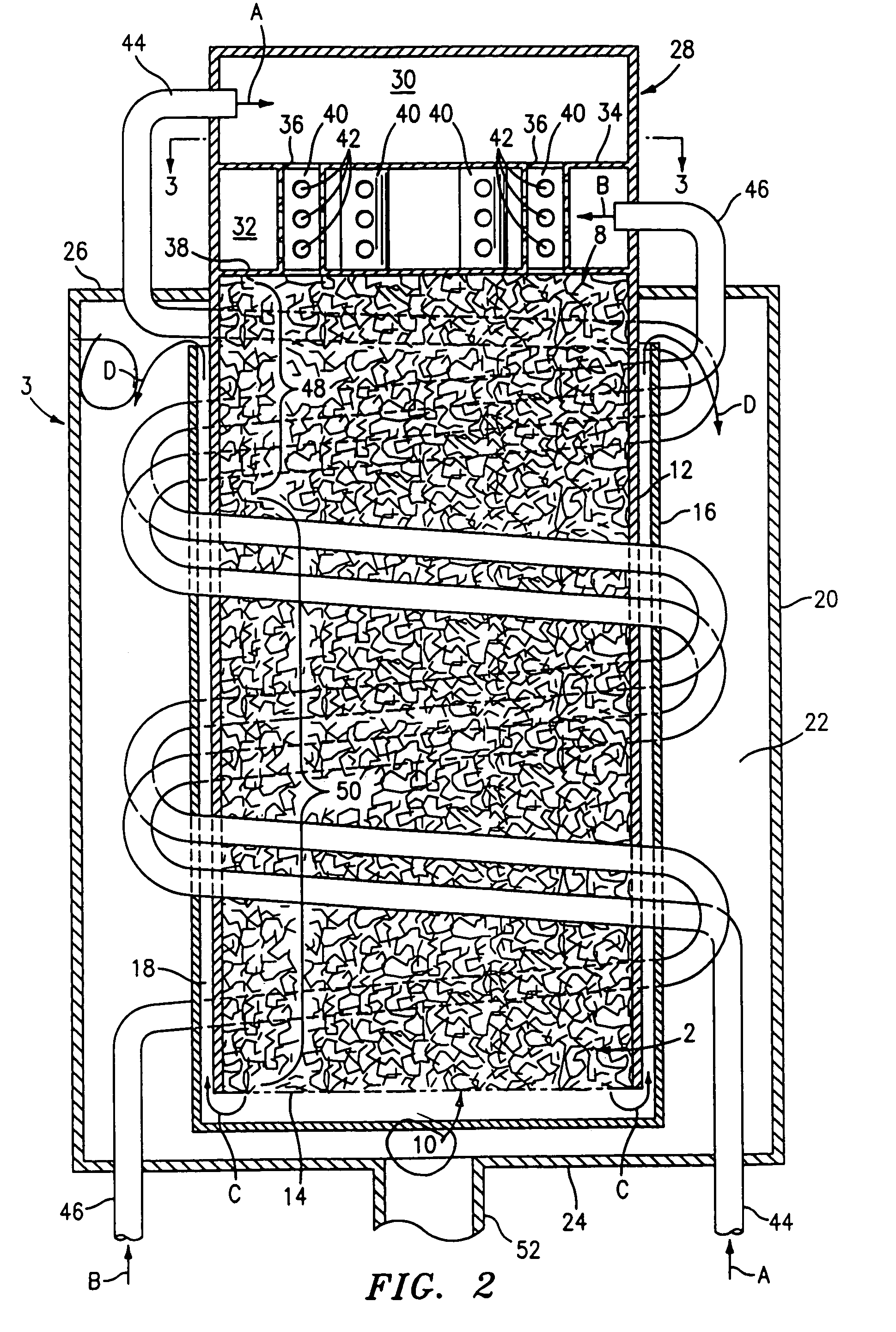

[0027]Referring now to the drawings, there is shown in FIG. 1 a perspective view of a cylindrical form of a catalyst bed formed in accordance with this invention, which bed is denoted generally by the numeral 2. The catalyst bed 2 is a monolithic open cell foam component which includes a lattice network of tendrils 4 which form a network of open cells 6 which are interconnected in the X, Y and Z directions within the bed 2. It will be appreciated that the catalyst bed 2 can be formed from a single monolith or from a plurality of thinner monoliths stacked one atop the other. The latter approach could simplify the differential catalyzation of the bed 2, and could also reduce thermal stresses imparted to the bed 2 during operation of the reformer. The interconnected open cells 6 are operable to form an enhanced fuel gas mixing and distribution flow path from end 8 to end 10 of the bed 2. The open cells 6 and the tendrils 4 also provide a very large catalyzable surface area in the bed 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com