Heat exchange copper tube provided with straight internal threads

A heat exchange copper tube and internal thread technology, which is applied to tubular elements, heat transfer modification, heat exchange equipment, etc., can solve the problems of small flow resistance, heat exchange area, flow dead zone of spiral grooves, and large flow resistance of threaded pipes. , to increase the degree of fluid turbulence, reduce the flow resistance, and increase the contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

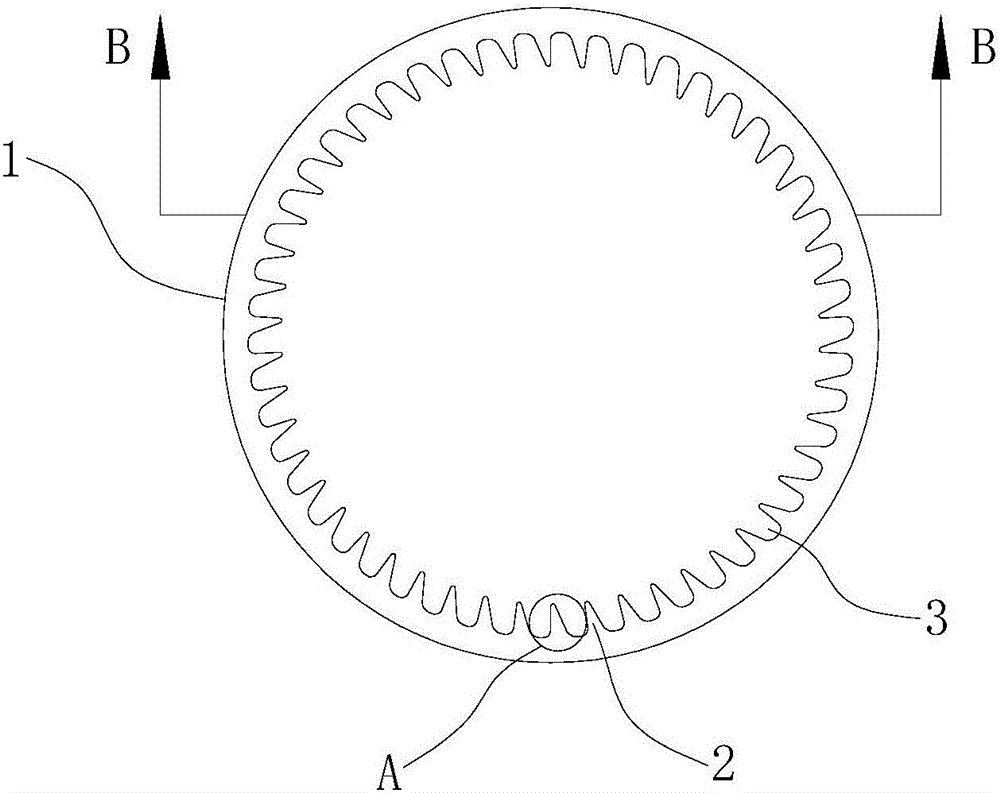

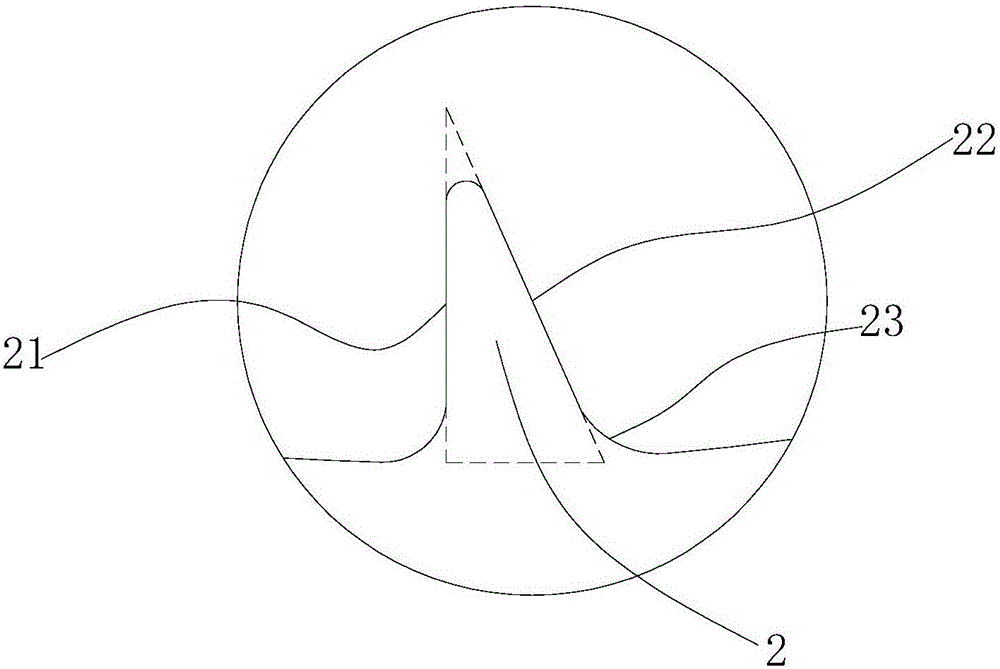

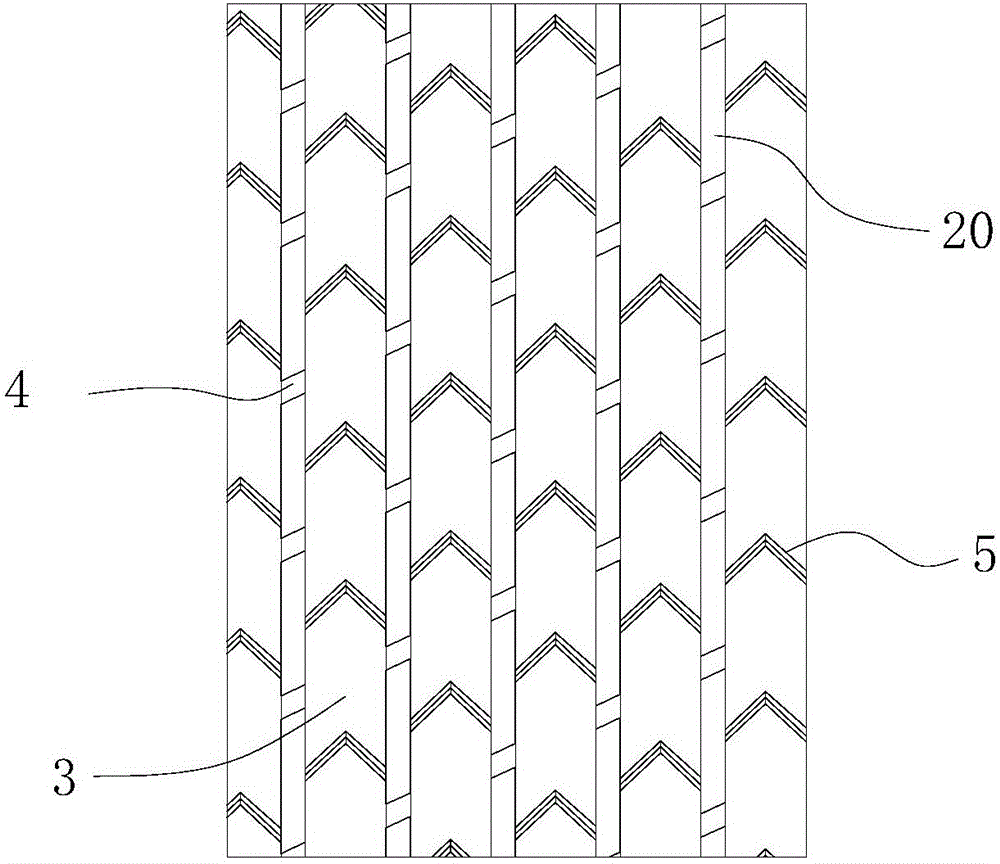

[0030] Such as figure 1 , figure 2 , image 3 As shown, a straight internal thread heat exchange copper tube includes a copper tube body 1, a number of evenly distributed right-angle teeth 2 are arranged on the inner surface of the copper tube body along the circumferential direction, and the two sides of the right-angle teeth are respectively a straight side and a The hypotenuse, wherein the extension line of the straight side crosses the center of the cross-section of the copper tube body to form a supporting straight side 21, the hypotenuse and the straight side intersect in a circular arc transition at the top of the right-angle tooth, the hypotenuse forms an expanded hypotenuse 22, and the tooth of the right-angle tooth The apex angle is 30°-45°, preferably 45°. In this way, during the tube expansion process, the expansion tube squeezes a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com