Dual enhanced tube for vapor generator

a technology of enhanced tubes and vapor generators, which is applied in the direction of indirect heat exchangers, heat generation using hot heat carriers, lighting and heating apparatus, etc., can solve the problems of reducing heat transfer and heat exchanger performance, and achieves improved heat transfer efficiency, increased heat transfer surface area, and improved heat transfer efficiency. effect of first zon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

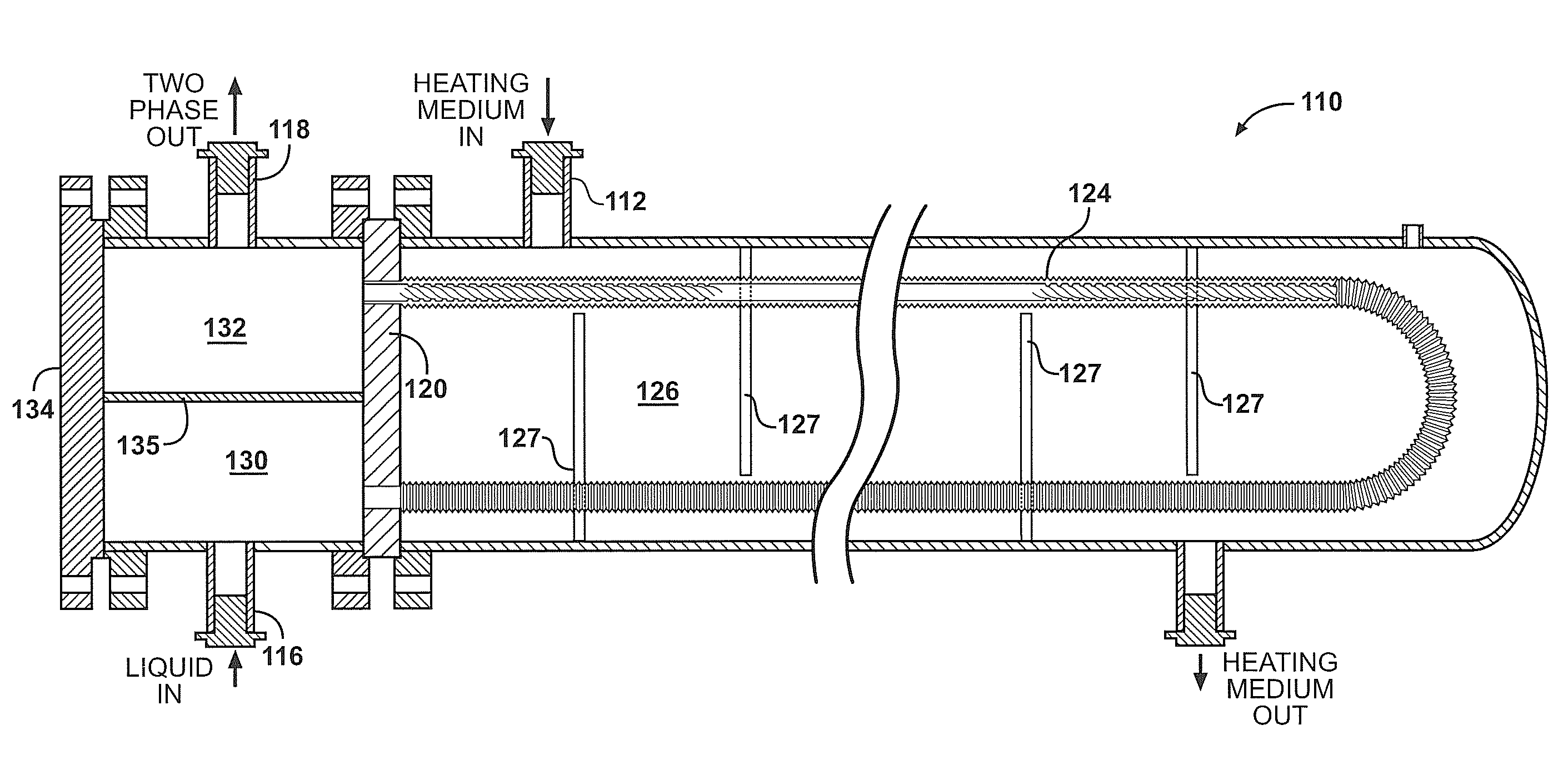

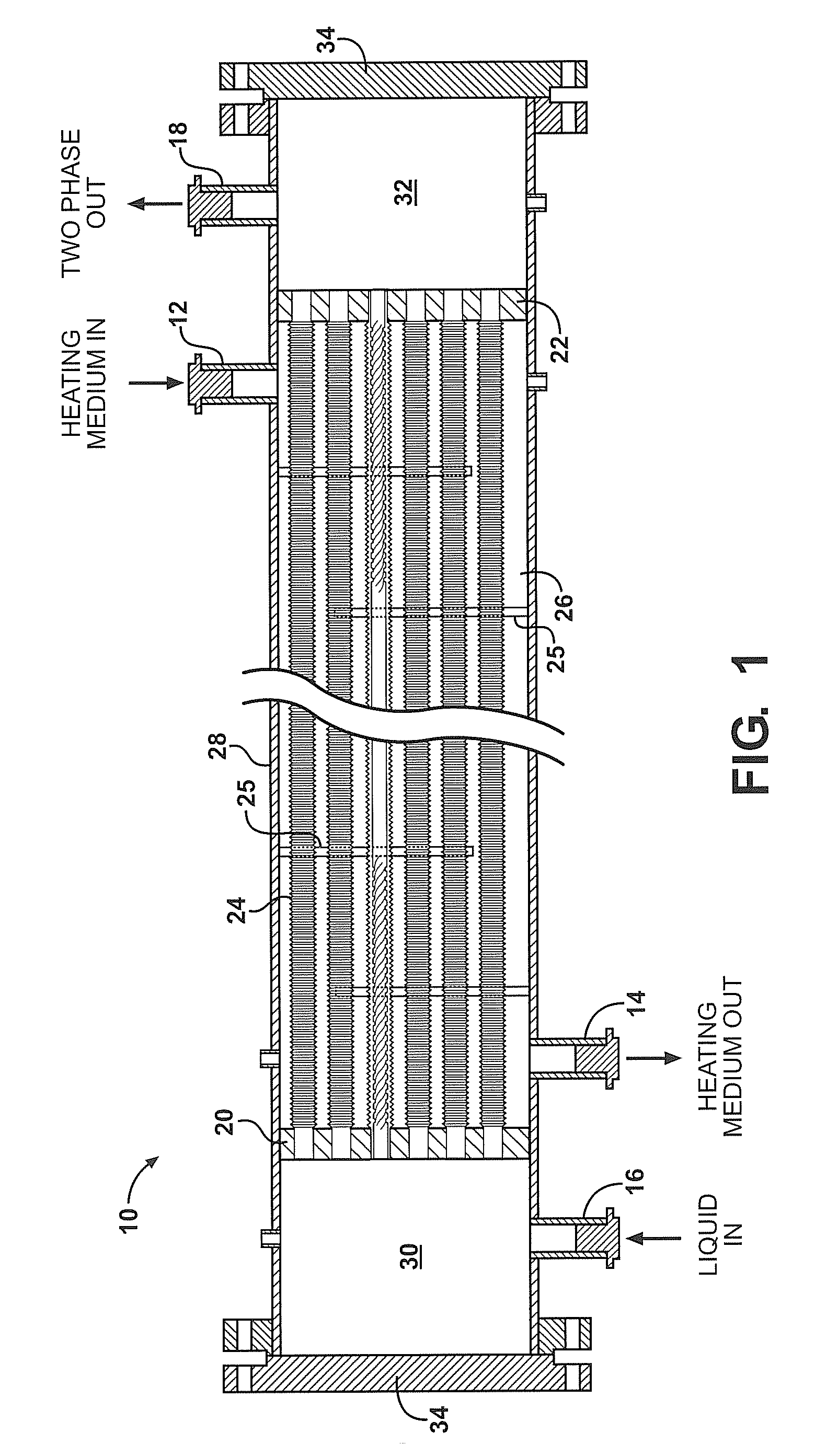

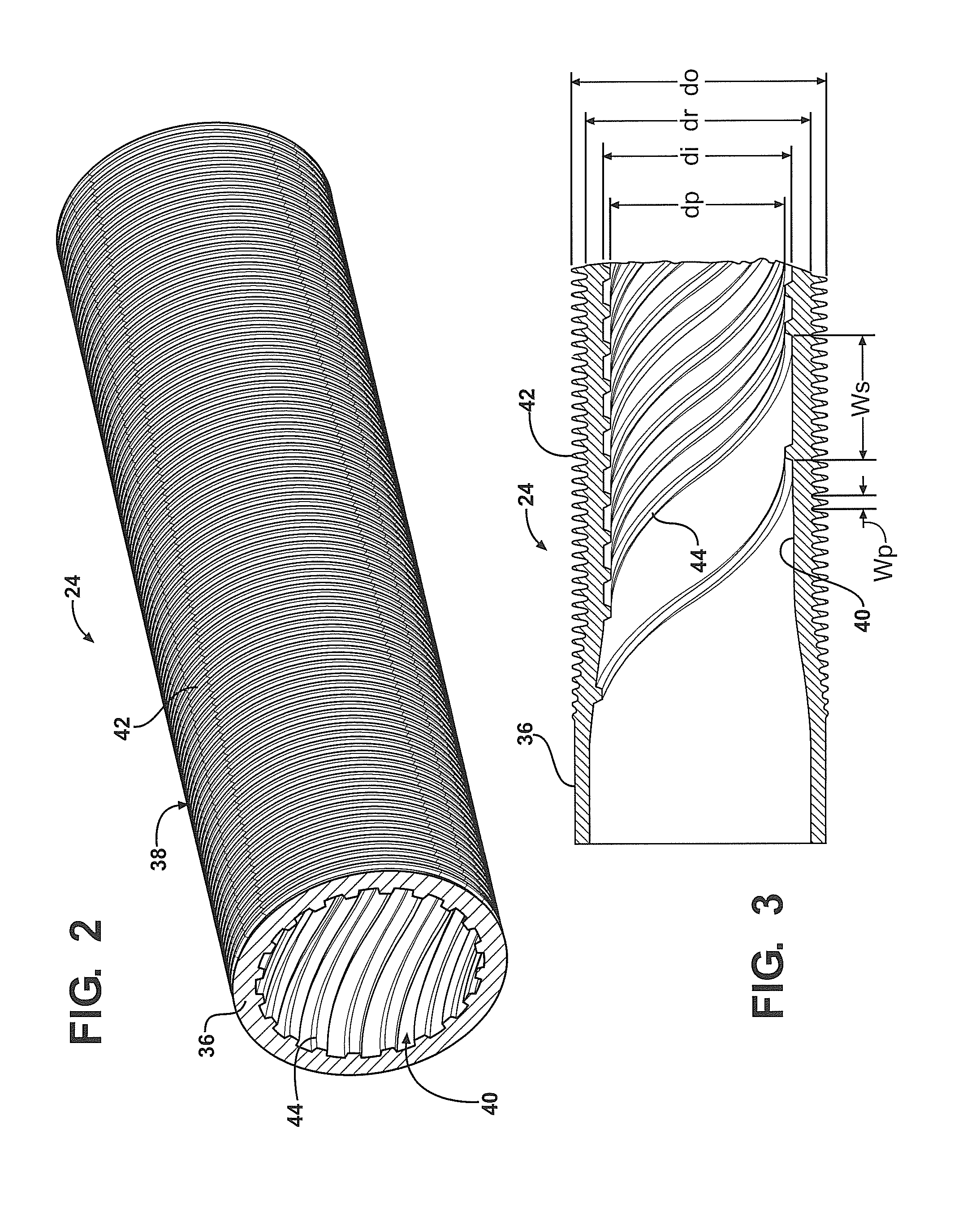

[0015]A heat exchanger assembly of the present invention is generally shown at 10 of FIG. 1. A first, or primary heating medium, enters the assembly 10 through heating medium inlet 12 and exits the assembly 10 through a heating medium outlet 14. The heating medium is contemplated by the inventors to be any liquid medium that is heated by an external energy source, for example, fossil fuel burning furnaces, nuclear energy reactors or solar energy collector fields. It is also contemplated by the inventors that the heating medium does not change phase, but remains in a liquid state throughout the process.

[0016]The second medium, or liquid, enters the assembly 10 through a liquid inlet 16 and exits the assembly 10 through a two phase flow outlet 18 after having been converted partially to vapor. It should be understood by those of skill in the art that the two phase flow will exit the assembly through the outlet 18. The second medium contemplated by the inventors is water that is conver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com