Rolling and ploughing-extrusion device and method for manufacturing three-dimensional internal and external finned tubes

A technology for manufacturing equipment and external fins, which is applied to the processing technology of internal and external finned tubes and the field of equipment, can solve the problems of limited extent of damage to the boundary layer, limited improvement of enhanced heat transfer coefficient, limited effect of expanding heat transfer surface, etc. Fin structure size, the effect of adjusting the fin structure size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

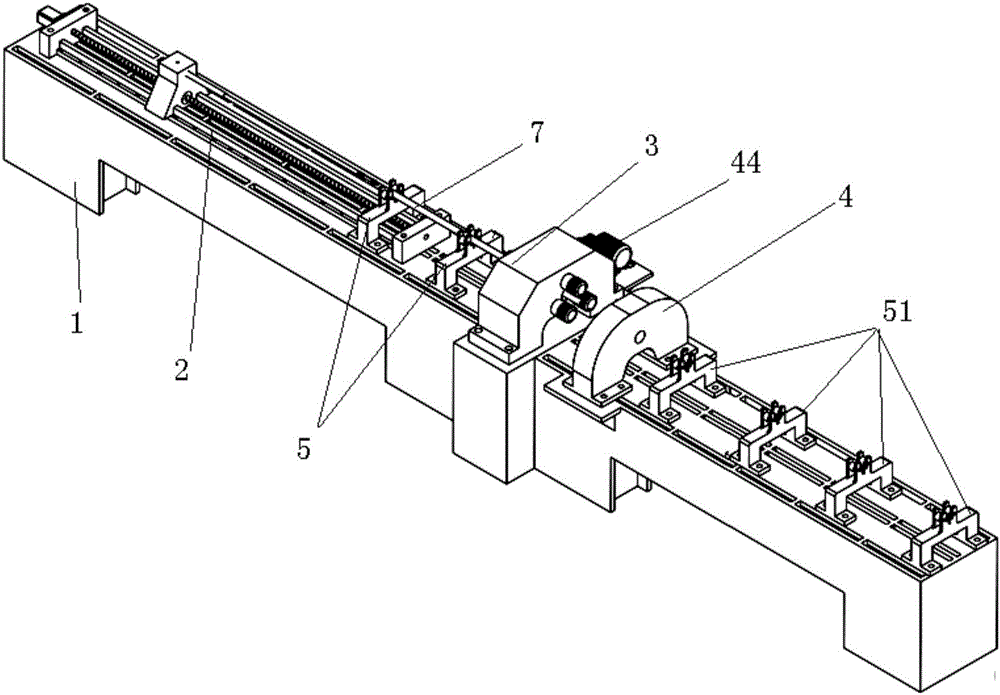

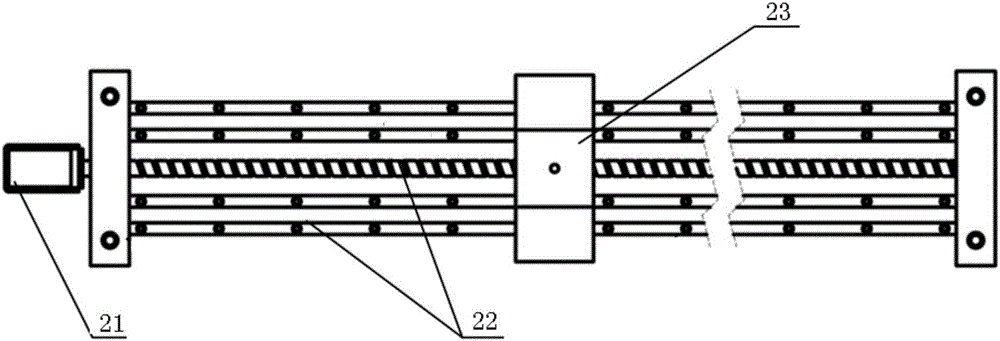

[0046] like Figures 1 to 9 shown. The invention discloses a rolling and plowing-extrusion three-dimensional inner and outer fin tube manufacturing equipment, which comprises a frame 1, an adjustable pull rod mechanism 2, a left support frame 5, a rotatable roll head 3, and outer fins. Plow cutter 4 and right bracket 51.

[0047] The adjustable pull rod mechanism 2 , the left material holder 5 , the rotatable roll head 3 , the outer fin plow cutter 4 and the right material holder 51 are arranged on the frame 1 in sequence.

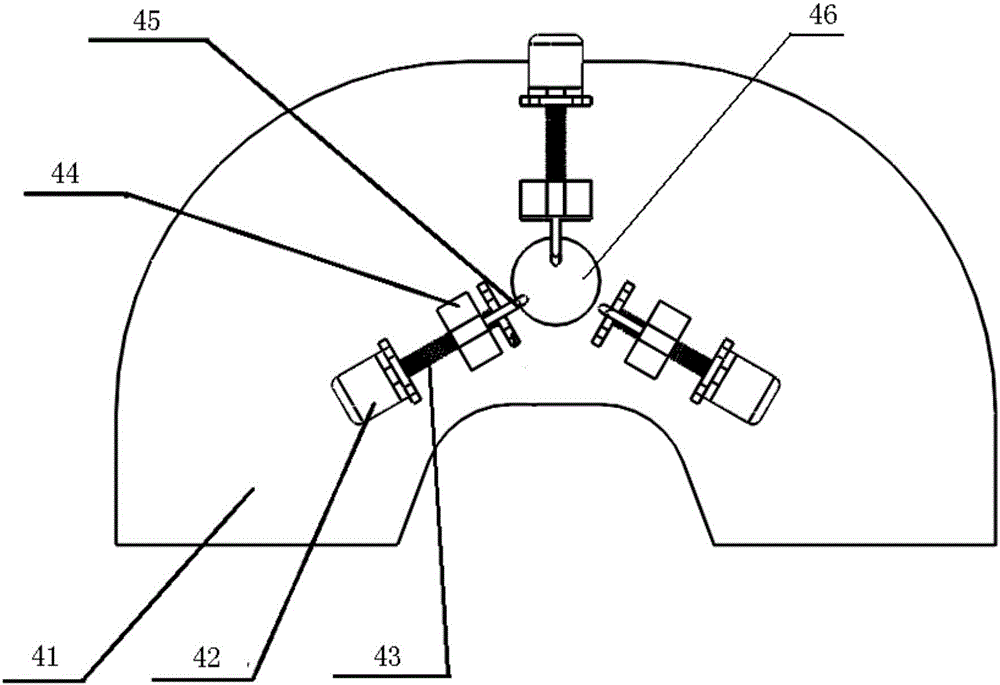

[0048] The roll head 3 is provided with an externally threaded roll mechanism for forming an externally threaded structure on the outer surface of the metal pipe 7; Internally threaded roller core mechanism 6 with continuous internal fin structure.

[0049] The externally threaded roll mechanism is symmetrically distributed on the periphery of the internally threaded roll core mechanism 6, and they form the roll station of the metal pipe 7. When the met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com