EGR cooling system with multiple EGR coolers

A technology of EGR cooler and cooling system, which is applied in the direction of charging system, machine/engine, adding non-fuel substances to fuel, etc., and can solve problems such as pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

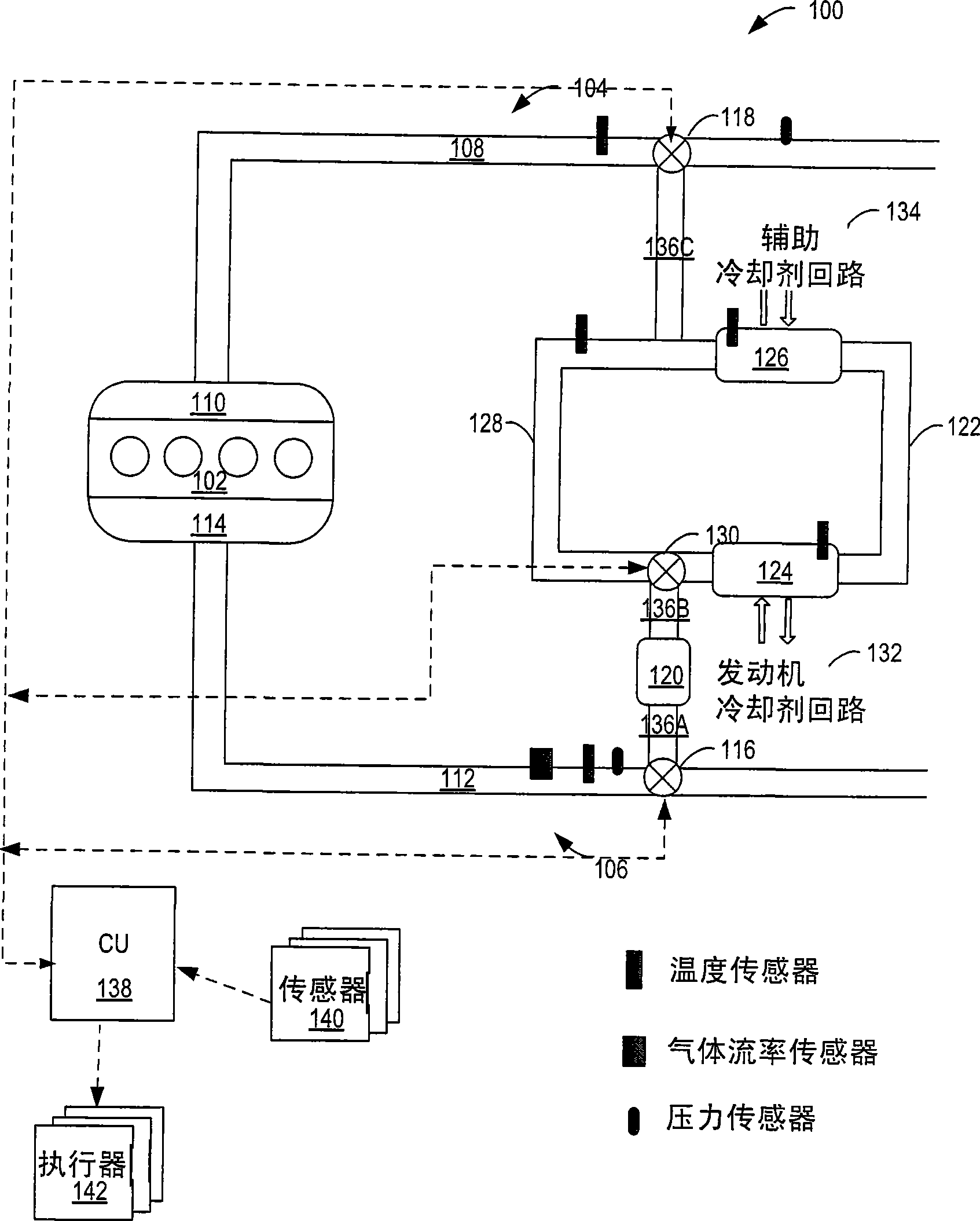

[0009] figure 1 An example EGR cooling system 100 configured to meet the EGR cooling requirements of an engine operable over a wide range of engine loads, such as a turbocharged diesel engine, while reducing EGR fouling is shown.

[0010] System 100 may include engine 102 coupled to intake system 104 and exhaust system 106 . Engine 102 may be various types of internal combustion engines, such as diesel engines, gasoline engines, and engines burning alternative fuels, such as biofuels and ethanol, or combinations thereof.

[0011] The intake system 104 may include an intake passage 108 connected to an intake manifold 110 , which in turn is connected to the engine 102 . The exhaust system 106 may include an exhaust passage 112 connected to an exhaust manifold 114 , which in turn is connected to the engine 102 .

[0012] EGR cooling system 100 may include an EGR valve 116 for diverting exhaust gas in exhaust passage 112 as EGR, and an EGR mixer 118 for mixing EGR with intake ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com