Test device for researching condensed phase particle collision discipline

A particle collision and test device technology, which is applied in the field of test devices for studying the collision law of condensed phase particles, can solve the problems that the collision law of condensed phase particles cannot be revealed, and the impact cannot be studied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

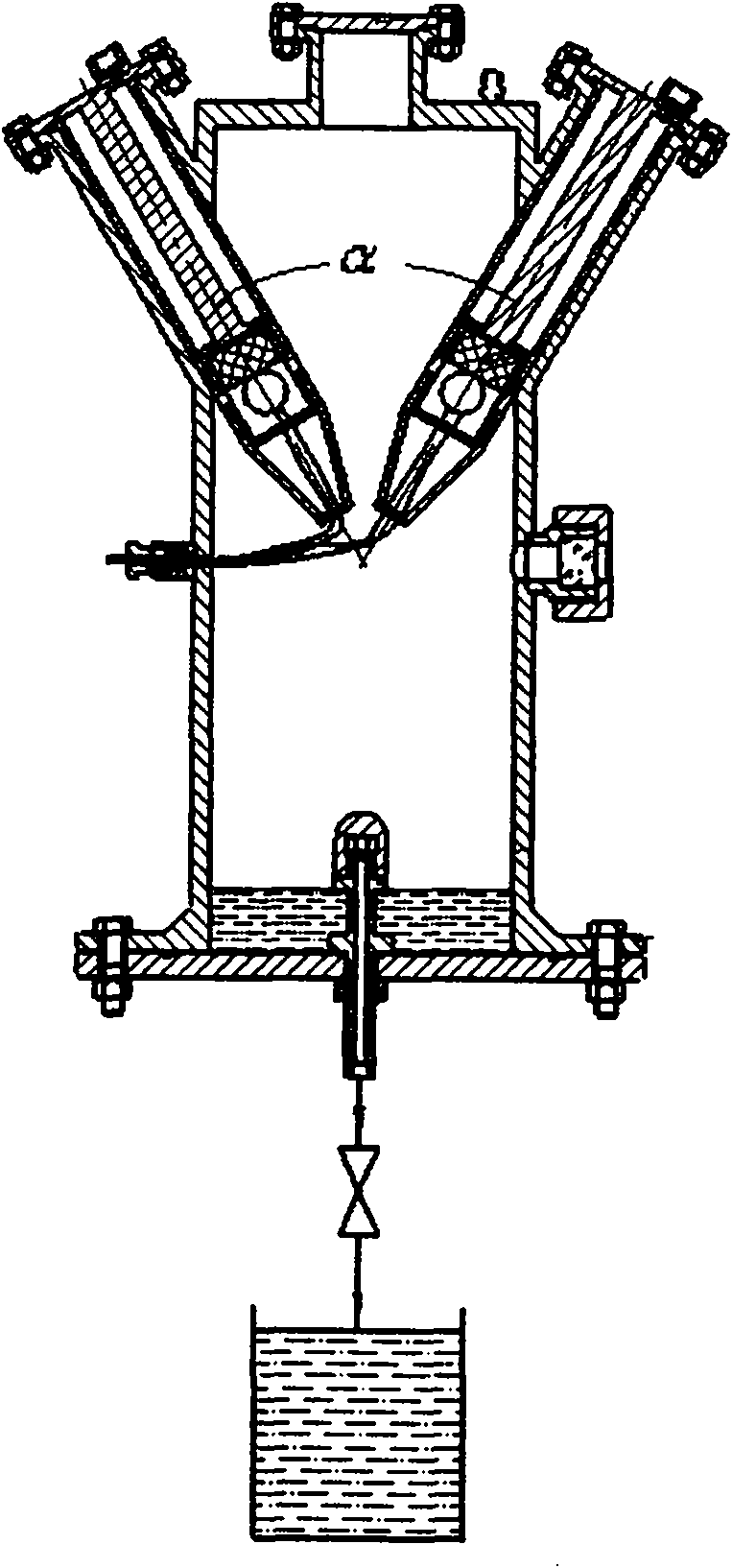

[0026] In this embodiment, the test device proposed by the present invention is used to carry out the collision test of condensed phase particles, and the influence of three impact factors such as particle velocity, collision angle and particle concentration on the collision law of condensed phase particles can be studied in a single way.

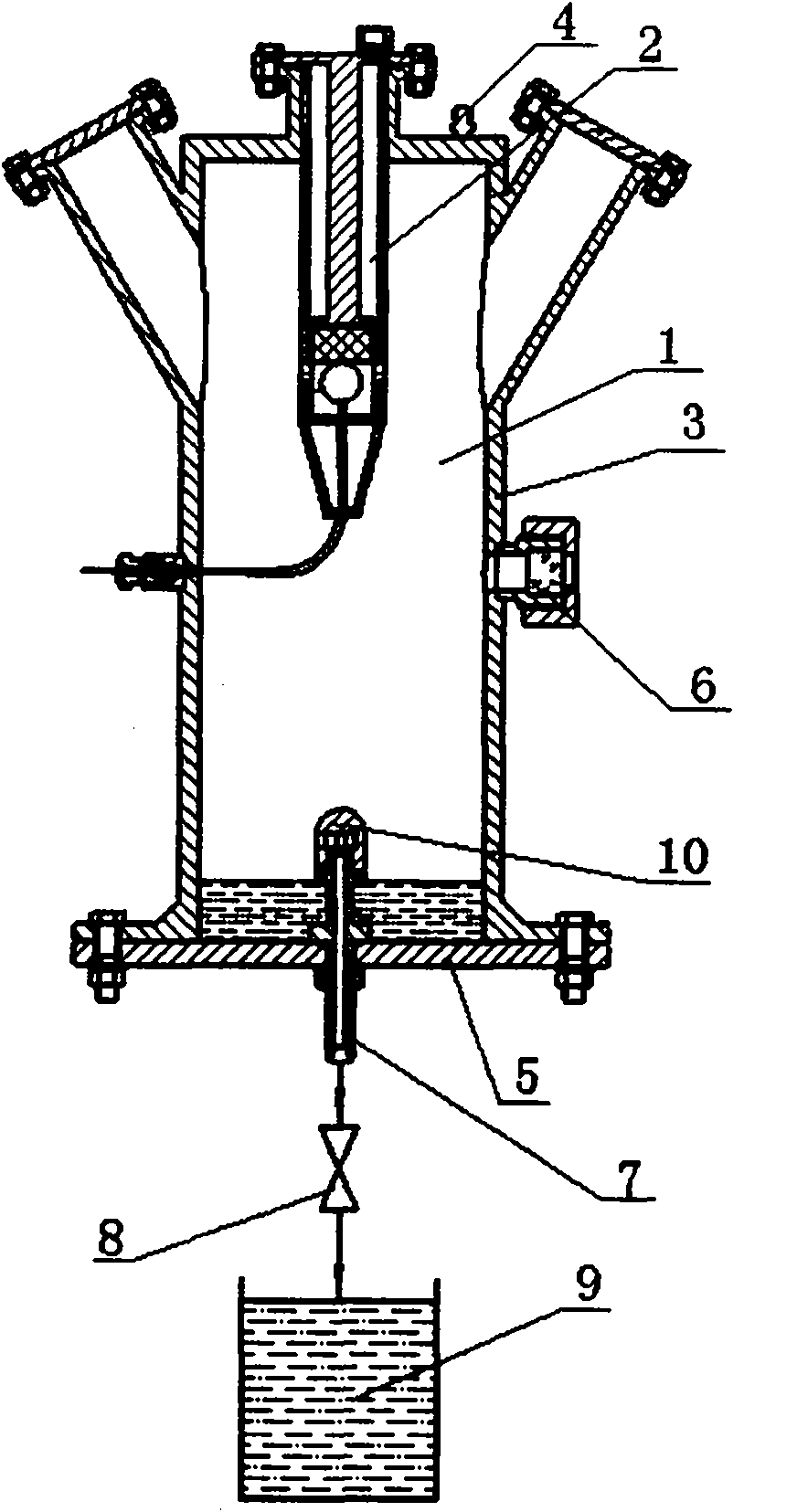

[0027] Refer to attached figure 1 And attached figure 2 , In this embodiment, the test device used includes a test section assembly 1 and a particle generator 2 .

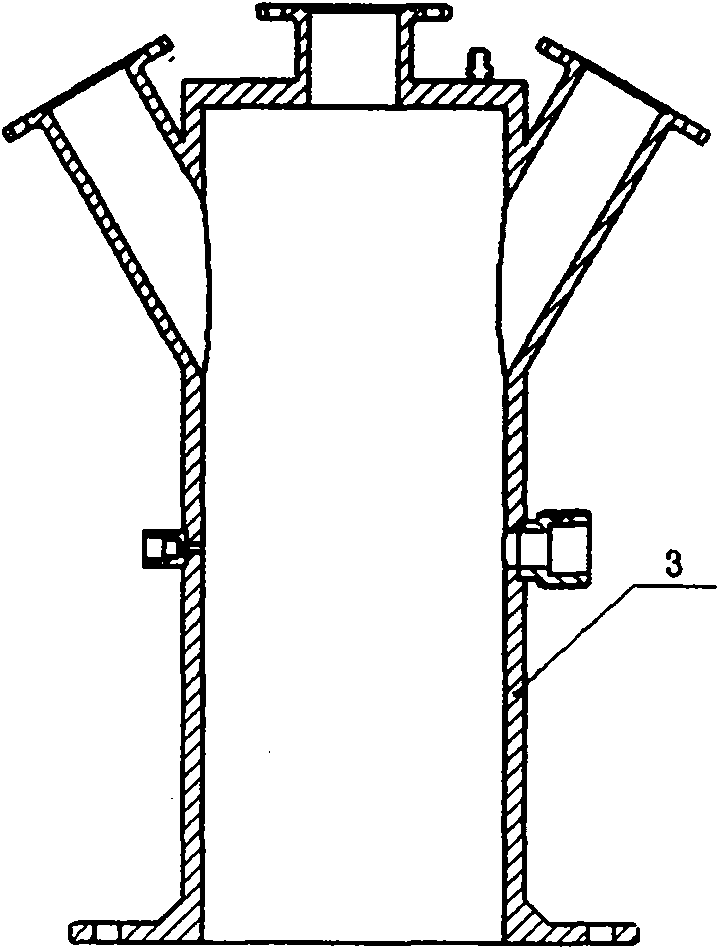

[0028] Refer to attached image 3 , the test section assembly 1 includes a test shell 3 and a ventilation joint 4, the test shell 3 is a hollow cylindrical structure, one end of which is an opening, and a hollow cylindrical connecting section protrudes from the other end surface, and the end of the hollow cylindrical connecting section There is a connecting flange for fixed connection with the particle generator 2, and a ventilation joint 4 is installed on the end face of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com