Double-layered crisscross-structure particle collision sensor based on PVDF (Polyvinylidene Fluoride)

A criss-crossing and particle collision technology is used in cutters, measurement of the properties of piezoelectric devices, agricultural machinery and tools, etc., to improve detection accuracy, reduce missed judgments, and improve accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

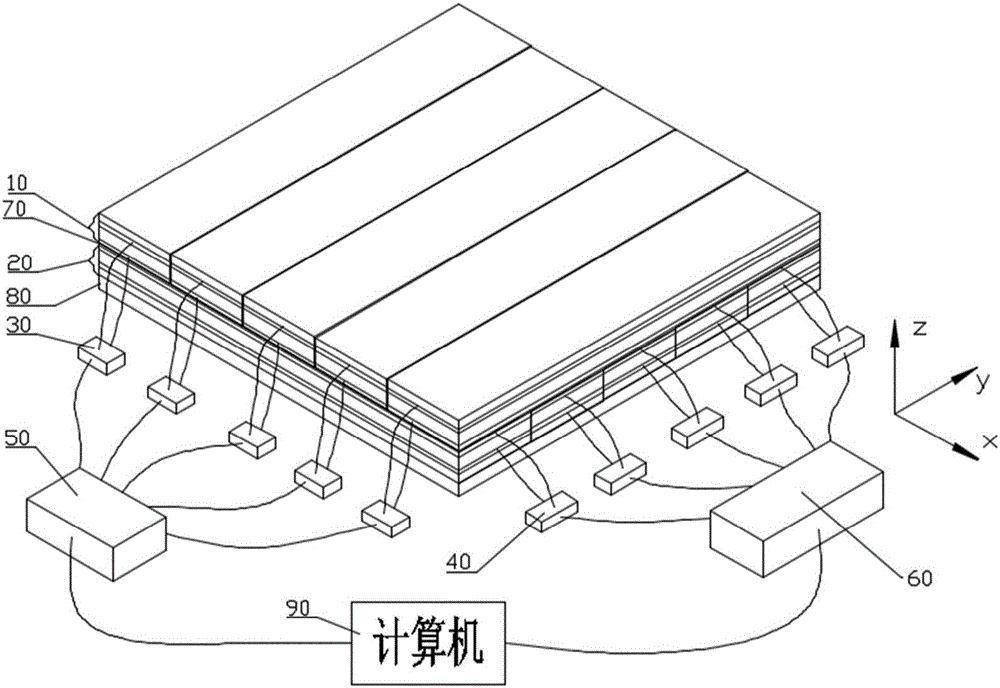

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

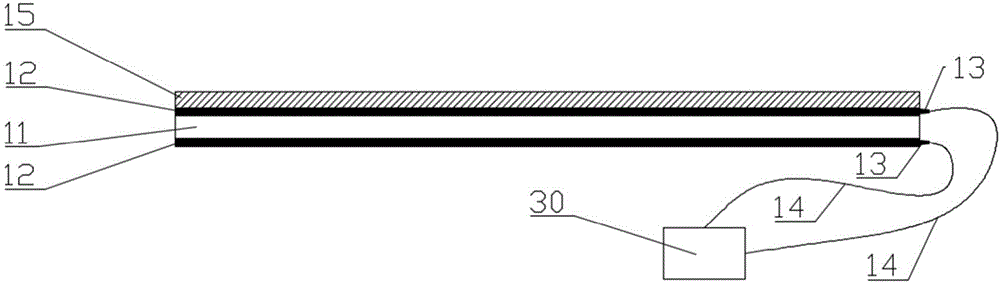

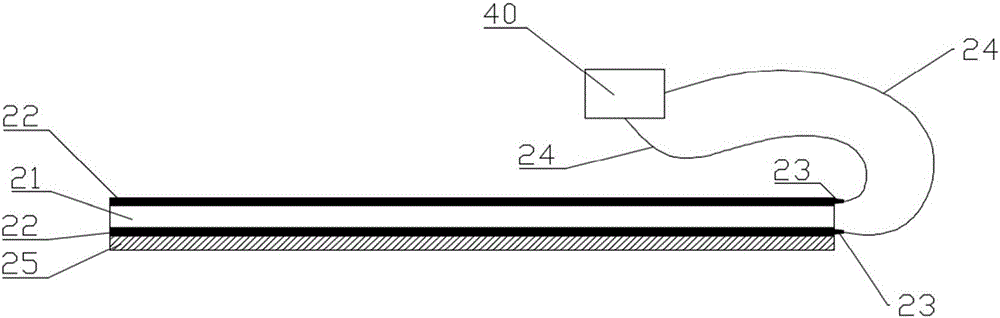

[0023] like figure 1 As shown, the present invention includes an x-direction sensor layer, an insulating sheet 70, a y-direction sensor layer, and a support plate 80 stacked sequentially from top to bottom, and the adjacent two layers of the above four layers are connected by organic glue, and the x-direction The sensor layer includes a plurality of parallel parallel and mutually insulated x-direction sensor units 10, the y-direction sensor layer includes a plurality of parallel parallel and mutually insulated y-direction sensor units 20, and the parallel arrangement direction of the x-direction sensor units 10 is perpendicular to the y-direction sensor unit 20 parallel arrangement directions; the x-direction sensor units 10 are all connected in parallel to the x-direction electrical signal processing device 50 through their respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com