High-temperature gas breakdown characteristic detection device and method under VFTO condition

A technology for breakdown characteristics and detection devices, applied in the direction of testing dielectric strength, etc., can solve problems such as differences in collisions between particles, imperfect detection methods for gas breakdown characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] An embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

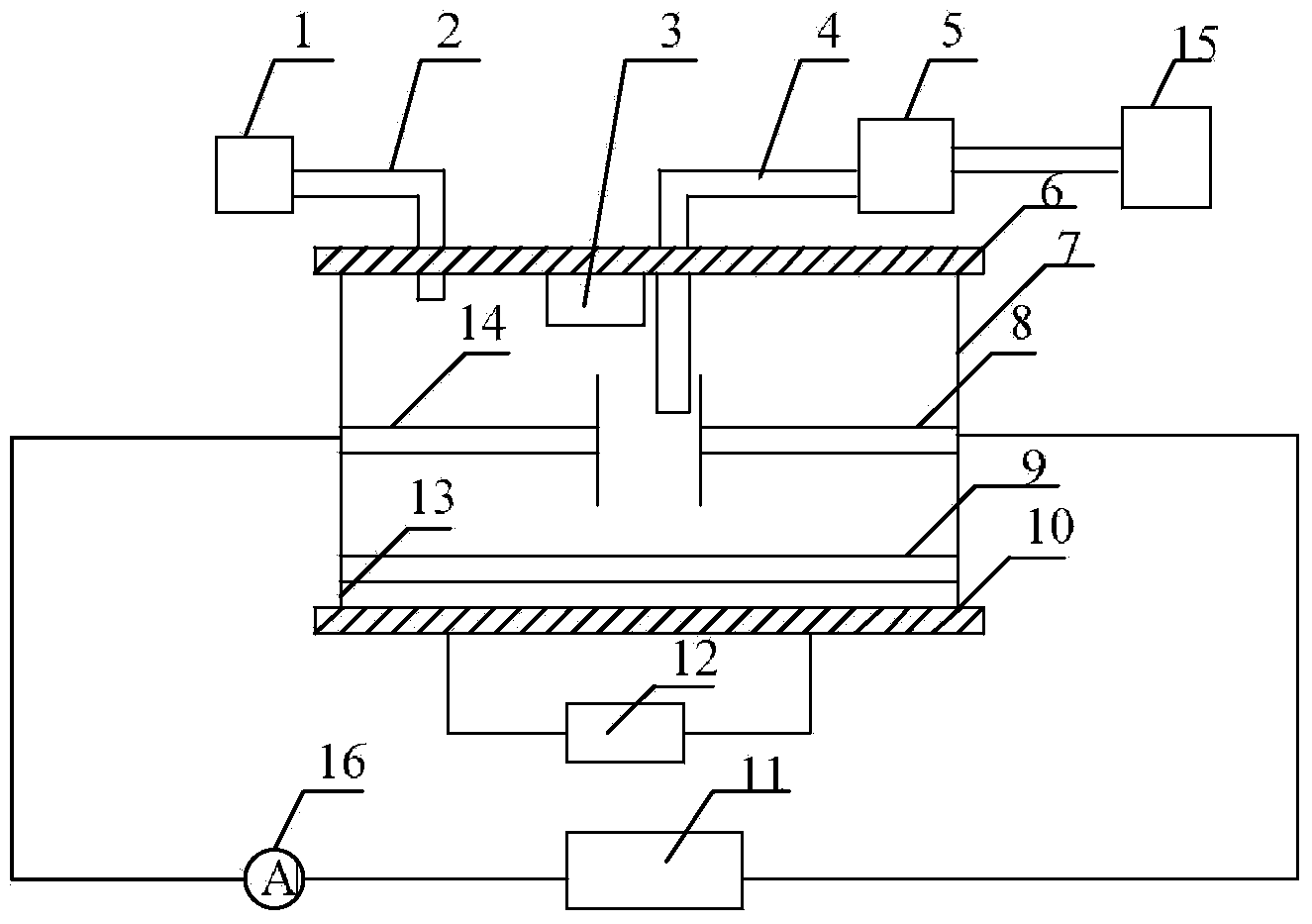

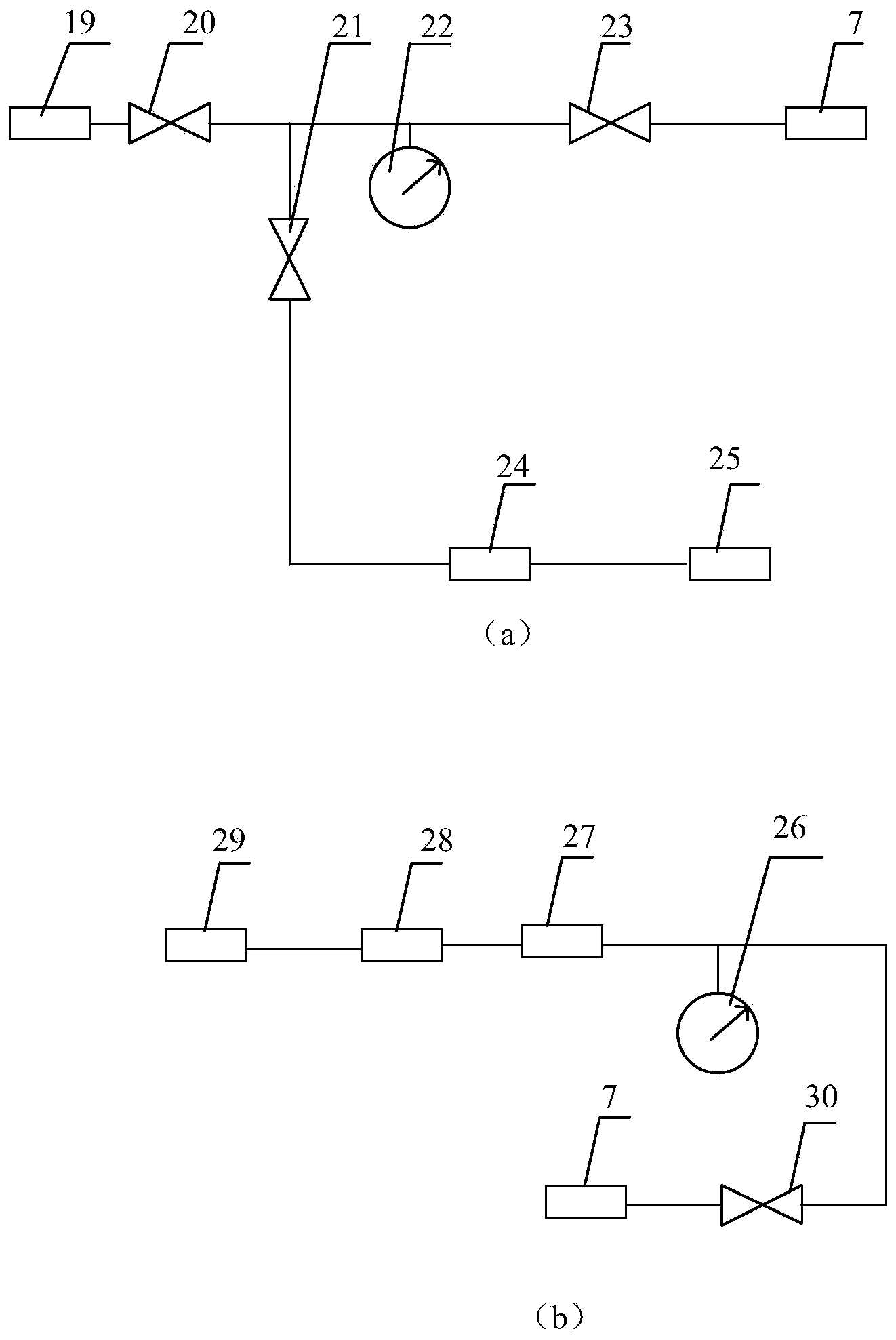

[0057] The high-temperature gas breakdown characteristic detection device under VFTO in this embodiment, such as figure 1 As shown, it includes: a gas enclosure 7, a heating unit, a discharge unit, a spectrometer 5, a thermometer 3, a gas charging and discharging and recovery unit 1, a voltage source 12, a VFTO generating unit 11, an ammeter 16 and a computer 15;

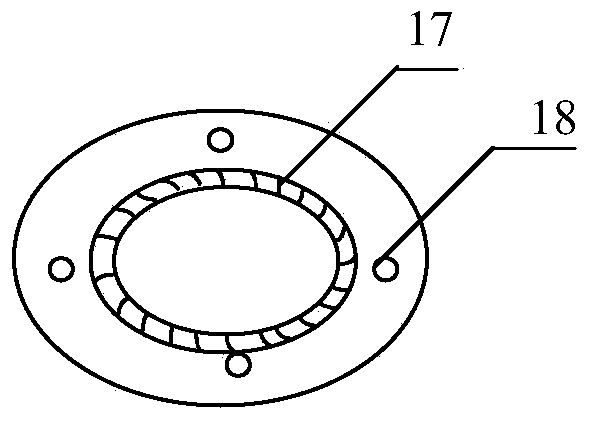

[0058] The gas-enclosed chamber 7 is a closed cylindrical barrel-shaped structure for holding gas. It is made of heat-insulating glass material with a wall thickness of about 20mm. 400mm; the top position of the gas confinement chamber 7 is connected to the upper flange 6, and the bottom position of the gas confinement chamber 7 is connected to the lower flange 10; the structure of the upper flange 6 and the lower flange 10 are the same, as figure 2 As shown, a circle groove with a width...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com