Piezoelectric sensor-based on-line measurement device and method for particle size distribution

A technology of piezoelectric sensor and particle size distribution, which is applied in the direction of measuring devices, particle size analysis, particle and sedimentation analysis, etc., can solve the problems of easy pollution and installation of the lens, and achieve the effect of small size, easy installation and reduced impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The invention provides an on-line measurement device and method for particle size distribution based on a piezoelectric sensor. Below in conjunction with accompanying drawing and embodiment the present invention is described as follows;

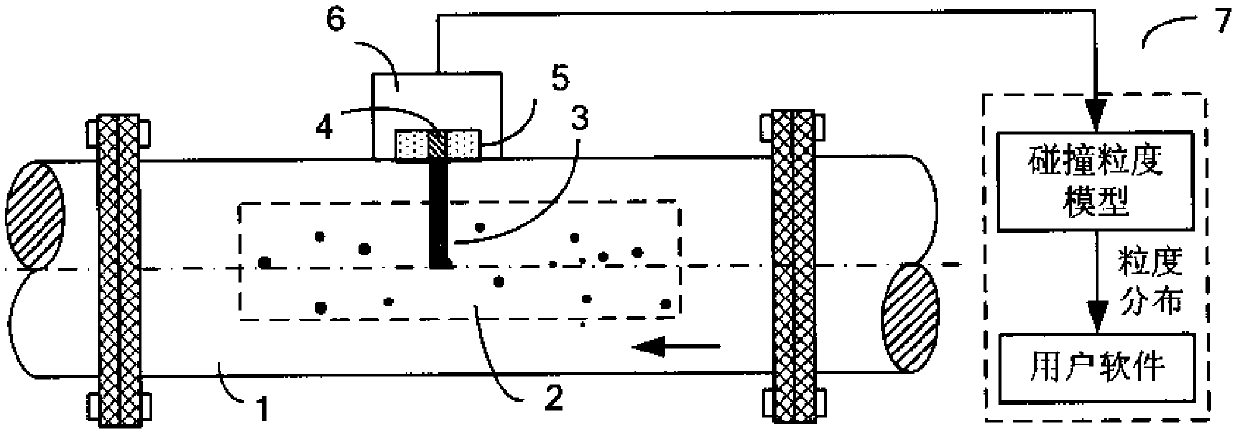

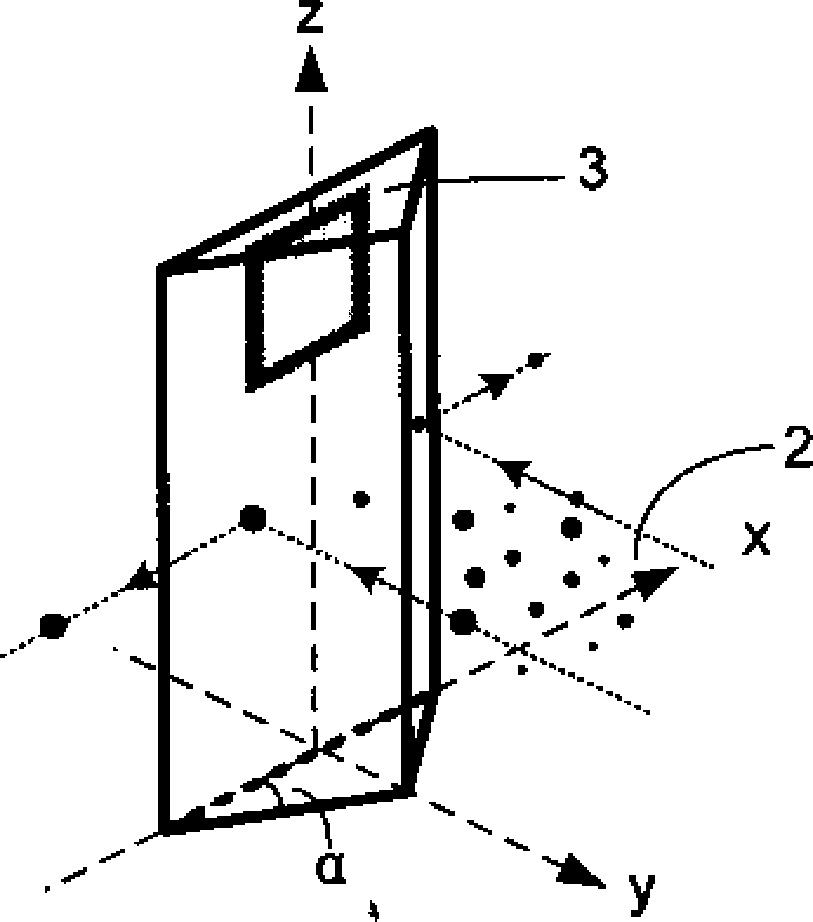

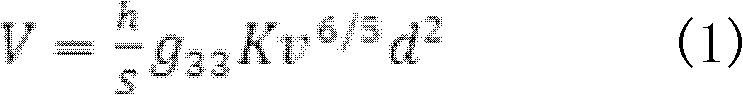

[0017] figure 1 Shown is a schematic diagram of the principle structure of the on-line measurement device for particle size distribution. In the figure, a collision sensing probe 3 is inserted in the middle of the gas-solid two-phase flow pipeline 1, and the collision sensing probe 3 is in the middle of the particle flow field 2; the length of the collision sensing probe is one-third to one-third of the diameter of the pipeline two. A piezoelectric sensor 4 is installed at the end of the collision sensing probe 3, and the piezoelectric sensor 4 is made of piezoelectric ceramics or piezoelectric film, so as to achieve the purpose of continuous use for a long time. The signal conditioning board and the data acquisition module 5 are fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com