Method and apparatus for measuring dynamic thermal stability of solid particles

A solid particle, thermal stability technology, applied in the direction of analyzing materials, instruments, etc., can solve the problem that solid particles cannot truly reflect the degree of crushing and pulverization of solid particles, cannot guide production, design, and there is no semi-coke test method and standard, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

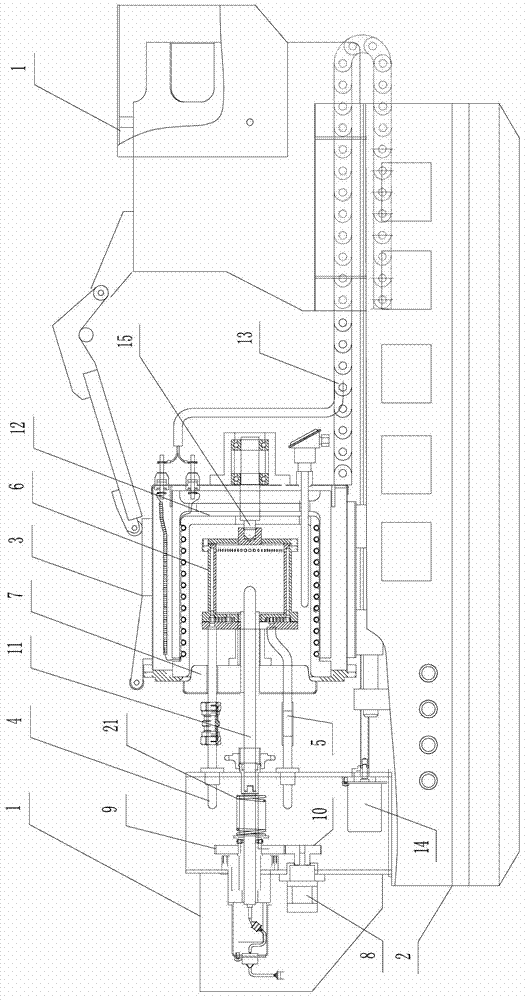

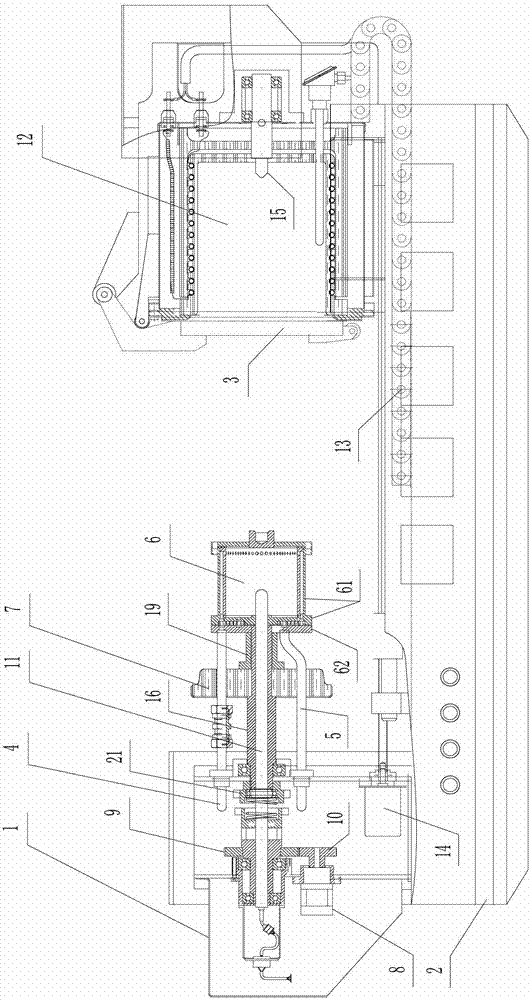

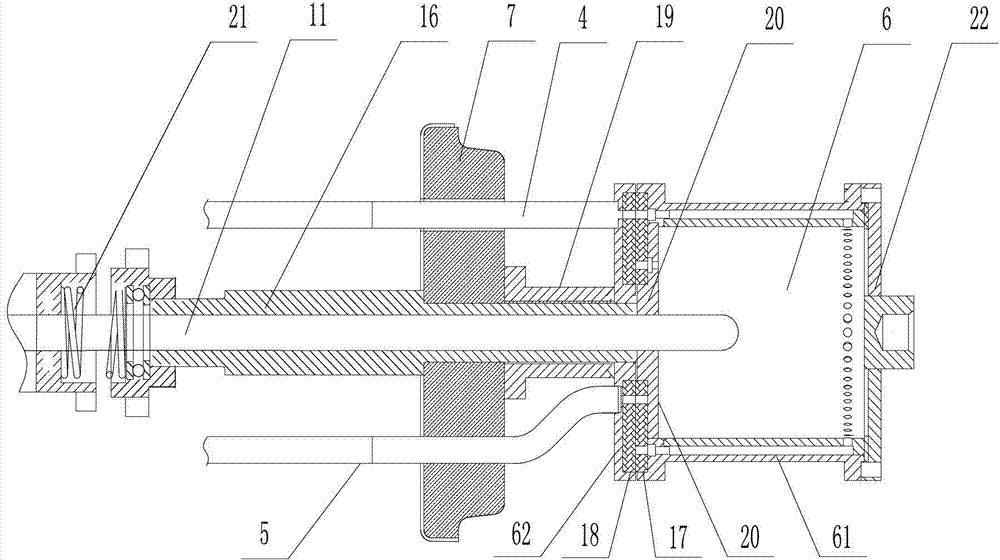

[0090] Specific implementation mode one: dynamic thermal stability determination method of coal

[0091] 1. According to the provisions of GB474, prepare about 1.5Kg of air-dried coal samples with a particle size of 6-13mm, and take 500cm after mixing. 3 Coal sample, weighing (accurate to 0.01g).

[0092] 2. Put the coal sample into the drum 6, and connect the drum 6 with the rotating shaft 11. Close the intake pipe 4 and the exhaust pipe 5 to isolate the air, and quickly send the drum 6 into the constant temperature zone of the heating furnace 12 that has been heated to 900°C. into the drum, the gas is discharged through the exhaust pipe 5 through the coal seam thickness.) Turn on the rotary switch, set the speed at 50r / min, adjust the furnace temperature to (850±15)°C, and make the coal sample rotate at this temperature for 30min . When the coal sample is just sent into the heating furnace 12, the furnace temperature may drop, and at this time, it is required to restore t...

specific Embodiment approach 2

[0107] Specific implementation mode two: method for measuring dynamic thermal stability of semi-coke

[0108] 1. Prepare about 1.5Kg of an air-dried semi-coke sample with a particle size of 6-13mm according to the provisions of GB474. After mixing, take a 500cm3 semi-coke sample and weigh it (accurate to 0.01g).

[0109] 2. Put the semi-coke sample into the drum 6, and connect the drum 6 with the rotating shaft 11. Close the intake pipe 4 and the exhaust pipe 5 to isolate the air, and quickly send the drum 6 into the constant temperature zone of the heating furnace 12 that has been heated to 900°C. into the rotating drum, and the gas is discharged through the exhaust pipe 5 through the thickness of the coal seam.) Turn on the rotary switch, set the rotating speed at 50r / min, adjust the furnace temperature to (850±15)°C, and make the semi-coke sample rotate at this temperature 30min. When the semi-coke sample is just sent into the heating furnace 12, the furnace temperature m...

specific Embodiment approach 3

[0124] Specific implementation mode three: dynamic thermal stability determination method of briquette

[0125] 1. From the industrial briquette samples taken in accordance with the regulations of MT / T915, select the briquettes without cracks and basically complete, randomly select about 500g of briquettes (about 10 pieces), and weigh the quasi-quality to 0.01g.

[0126] 2. Put the molded coal sample into the drum 6, and connect the drum 6 with the rotating shaft 11. Close the intake pipe 4 and the exhaust pipe 5 to isolate the air, and quickly send the drum 6 into the constant temperature zone of the heating furnace 12 that has been heated to 900 °C in advance. into the drum, and the gas is discharged from the exhaust pipe 5 through the thick coal seam.) Turn on the rotary switch, set the speed at 50r / min, and adjust the furnace temperature to (850±15)°C, so that the briquette sample is at this temperature Turn for 30min. When the briquette sample is just sent into the heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com