Processing method of tartary buckwheat tea

A processing method, the technology of tartary buckwheat tea, which is applied in the processing field of tartary buckwheat tea, can solve the problems of loose particle structure, unflavored tea soup, burnt smell, etc., and achieve the effect of increasing material density, fine particle skin, and preventing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

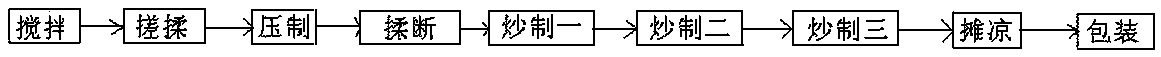

[0021] A processing method of tartary buckwheat tea, comprising the following steps;

[0022] (1) Add 20% water to the tartary buckwheat powder and stir evenly;

[0023] (2) Put the uniformly stirred material into the friction kneading machine, rub, knead, and form a rice ball-like material, rub against each other to heat up, stir for 30 minutes, and then get a rice ball-like material with a smooth surface, take it out stand-by;

[0024] (3) Put the rice ball-shaped material with a smooth surface into the noodle making machine, and extrude it into a cylindrical strip.

[0025] (4) Place the extruded cylindrical strip material on a square sieve with an aperture of 6 mm, and knead it into granules for later use;

[0026] (5) Frying 1: Put the granular material into the first frying pan without heating, and stir fry at room temperature for 120 minutes. The surface of the granular material will lose moisture and the skin will be smooth. a stir frying pan;

[0027] (6) Stir-fry...

Embodiment 2

[0034] A processing method of tartary buckwheat tea, comprising the following steps;

[0035] (1) Add 25% water to the tartary buckwheat powder and stir evenly;

[0036] (2) Put the uniformly stirred material into the friction kneading machine, rub, knead, and form a rice ball-like material, rub against each other to heat up, stir for 35 minutes, and then get a rice ball-like material with a smooth surface, take it out stand-by;

[0037] (3) Put the rice ball-shaped material with a smooth surface into the noodle making machine, and extrude it into a cylindrical strip.

[0038] (4) Place the extruded cylindrical strip material on a square sieve with an aperture of 8 mm, and knead it into granules for later use;

[0039] (5) Frying 1: Put the granular material into the first frying pan without heating, and stir fry at room temperature for 130 minutes. The moisture on the skin of the granular material will be lost and the skin will be smooth. a stir frying pan;

[0040] (6) S...

Embodiment 3

[0047] A processing method of tartary buckwheat tea, comprising the following steps;

[0048] (1) Add 30% water to the tartary buckwheat powder and stir evenly;

[0049] (2) Put the uniformly stirred material into the friction kneading machine, rub, knead, and form a rice ball-like material, rub against each other to heat up, and stir for 40 minutes to get a rice ball-like material with a smooth surface, take it out stand-by;

[0050] (3) Put the rice ball-shaped material with a smooth surface into the noodle making machine, and extrude it into a cylindrical strip.

[0051](4) Place the extruded cylindrical strip material on a square sieve with an aperture of 10 mm, and break it into granules for later use;

[0052] (5) Frying 1: Put the granular material into the first frying pan without heating, and stir fry at room temperature for 140 minutes. The moisture on the skin of the granular material will be lost and the skin will be smooth. a stir frying pan;

[0053] (6) Stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com