Method for measuring diameter and coordinate position of spatial curved surface micro-hole in non-contact mode

A technology of non-contact measurement and coordinate position, which is applied in the field of non-contact measurement of the diameter and coordinate position of micro-holes on the space surface, measuring the diameter and coordinate position of micro-holes on the space surface of the blade body, and can solve the problem of inability to extract data and evaluation, and micro-hole images Blur and other problems, to achieve the effect of improving the level of processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0078] Air film holes in high-pressure turbine blades of aero-engines are tiny holes in the blade body, generally in the range of Φ0.3mm to Φ0.5mm, and are typical tiny holes on the space surface. Therefore, the present invention takes the detection of the diameter of the gas film hole of the high-pressure turbine blade and the coordinate position size as the embodiment of the present invention.

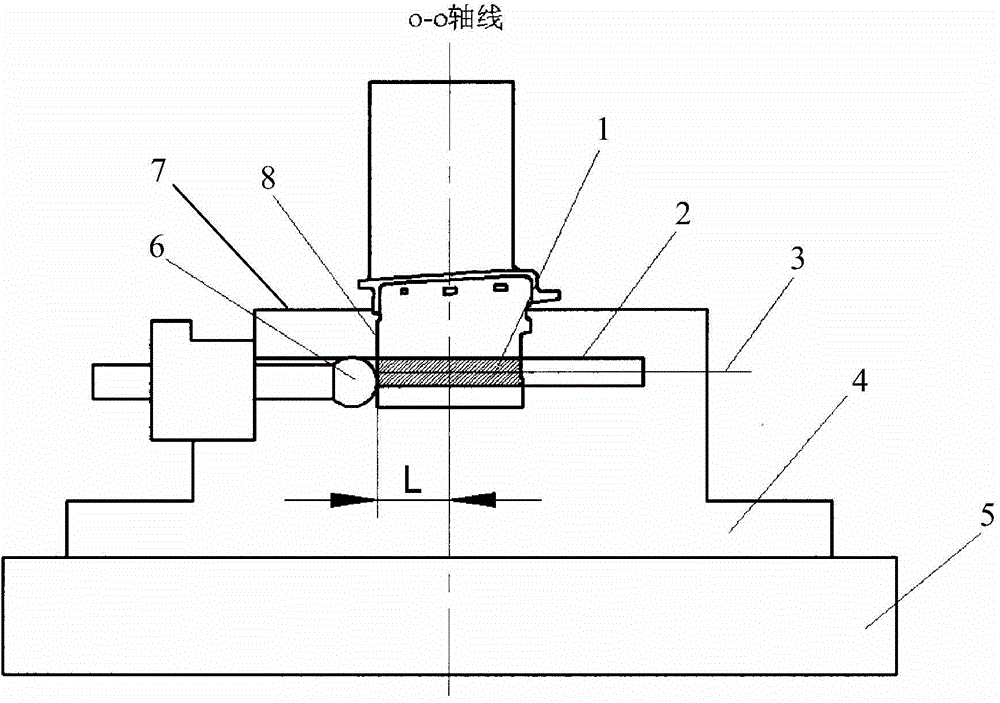

[0079] (1) Establishment of blade O-O axis

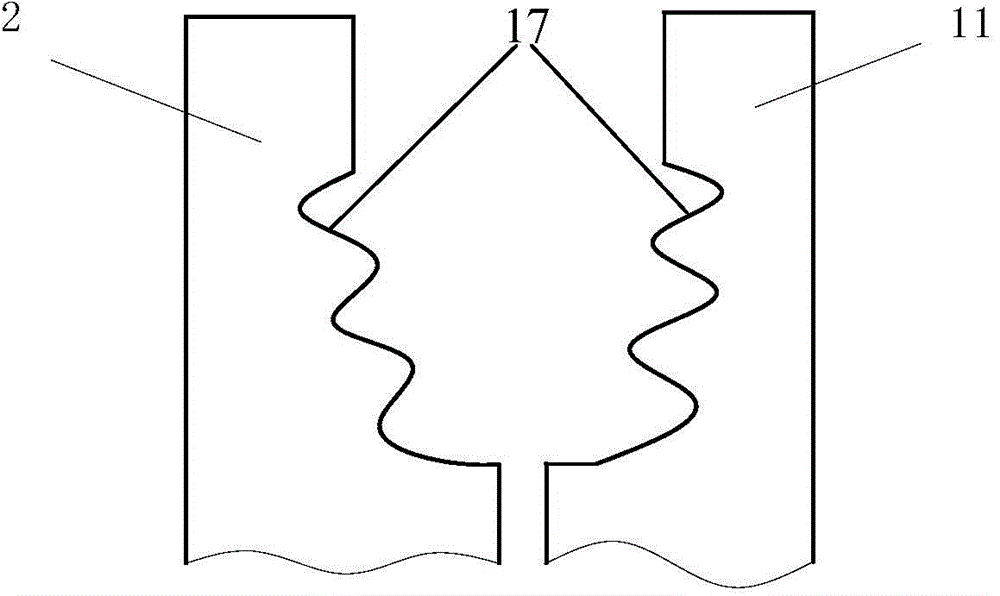

[0080] Adjust the positioning ball 6 according to the position of the blade O-O axis, so that the distance from the positioning ball 6 to the central rotation axis of the blade positioning device 4 is L, which is equal to the distance from the blade T reference plane 8 to the blade O-O axis, so as to ensure that the blade is in the tenon teeth 1 Accurate positioning in the length direction.

[0081] The clamping mechanism of the blade positioning device 4 adopts the principle of micro-deformation in design to avoid positioning errors caus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com