Fuel particle hot collision recovery coefficient measurement device and measurement method

A technology of restitution coefficient and measuring device, which is applied in the fields of energy engineering and chemical engineering, and can solve problems such as the inability to measure the restitution coefficient of fuel particle collisions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

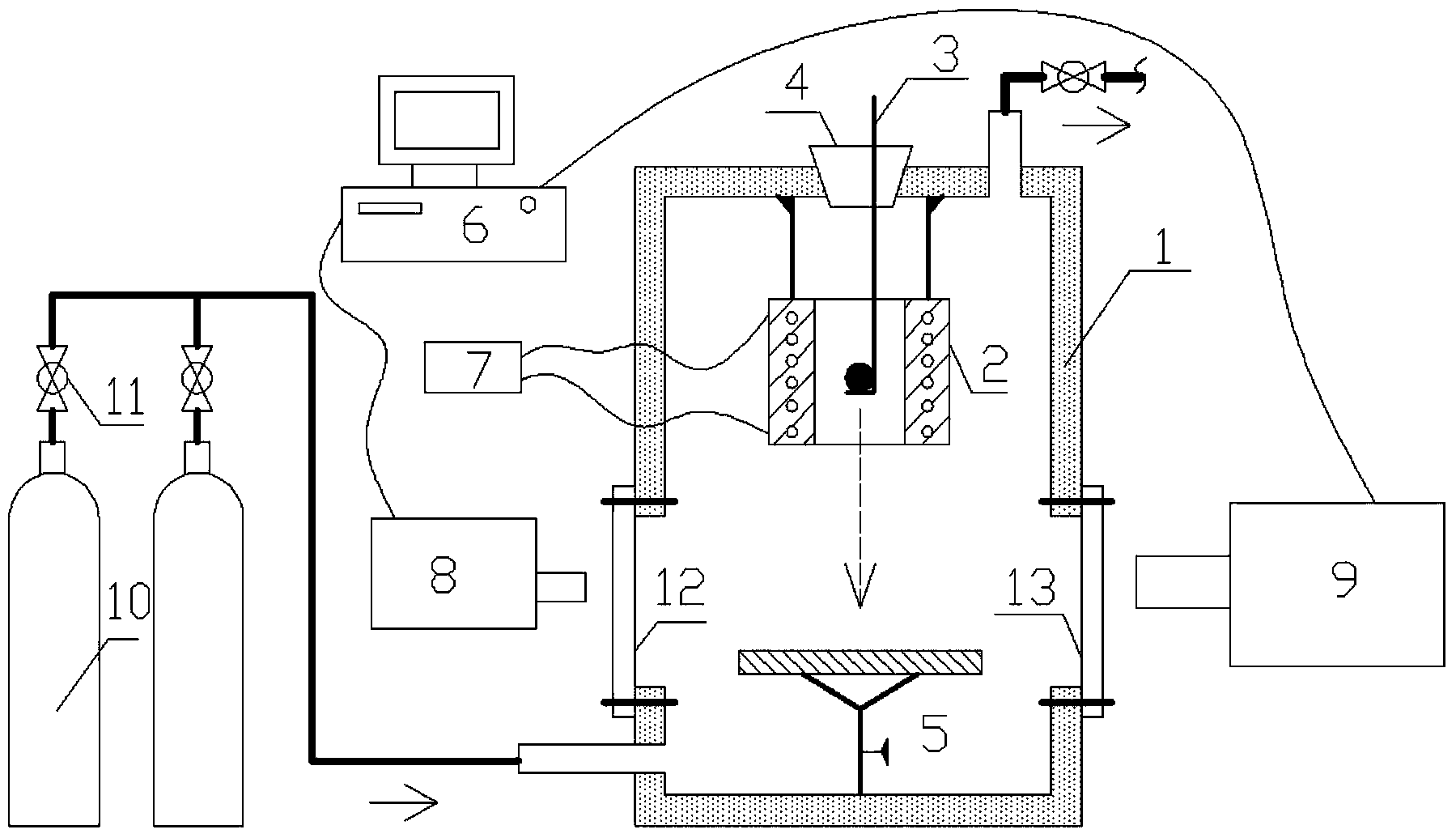

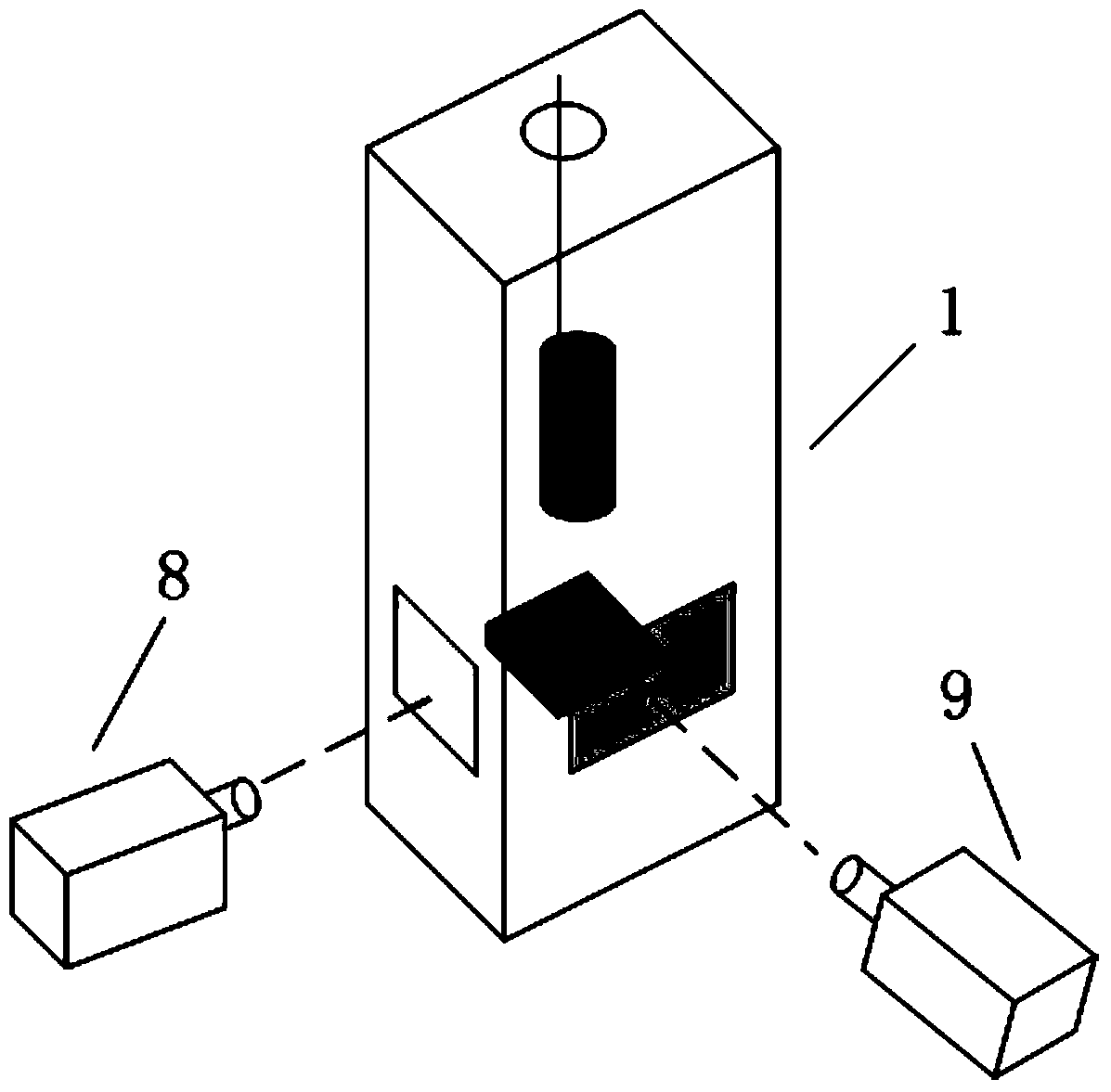

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

[0032] A measuring device for thermal state collision recovery coefficient of solid fuel particles, comprising a hollow sealed chamber 1 made of stainless steel, the sealed chamber 1 is provided with an air inlet and an air outlet, and the air inlet is connected to the air inlet through a pipeline. source, and a gas flow regulating valve 11 is set between the air inlet and the gas source, and a valve is set on the gas outlet to control whether it communicates with the outside world. Open the valve at the gas outlet during the use of the device to remove the smoke and excess reaction gas generated by combustion. After use, close the gas flow regulating valve 11 and the valve at the gas outlet to avoid the entry of water vapor in the air.

[0033]The upper position inside the sealed chamber 1 is fixed with a tubular electric heating furnace 2, and the axial direction of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com