Preparation method of high-purity nano aluminum nitride

A nano-aluminum nitride, high-purity technology, applied in chemical instruments and methods, nitrogen compounds, nanotechnology, etc., can solve problems such as large environmental impact and complex aluminum nitride process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] Based on the technical problems that the existing nano-aluminum nitride preparation process is complicated and causes great environmental pollution, the present invention provides a preparation method of high-purity nano-aluminum nitride.

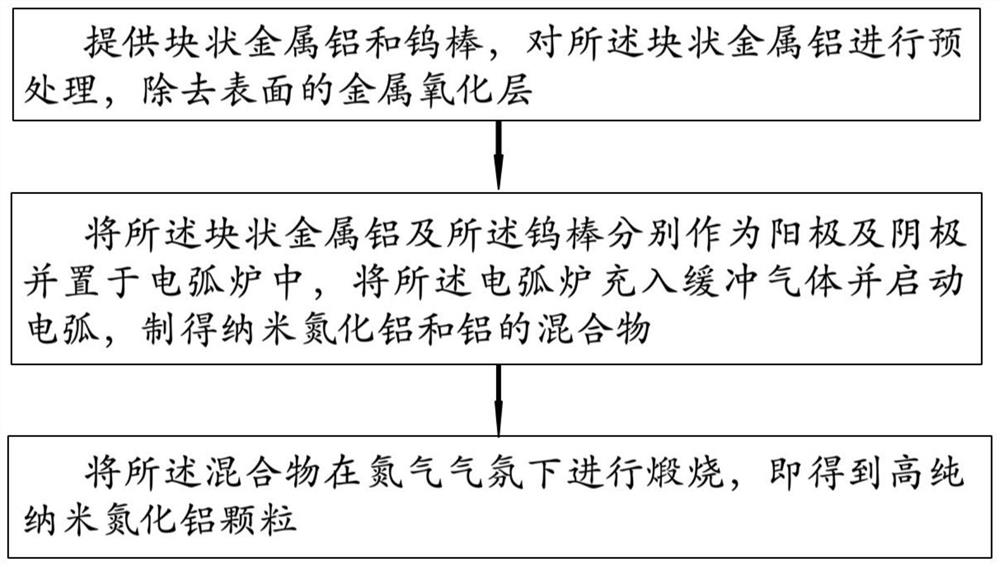

[0037] Such as figure 1 As shown, a method for preparing high-purity nano-aluminum nitride provided by an embodiment of the present invention includes the following steps:

[0038] Provide bulk metal aluminum and tungsten rods, pretreat the bulk metal aluminum, and remove the metal oxide layer on the surface;

[0039] The bulk metal aluminum and the tungsten rod are respectively used as an anode and a cathode and placed in an electric arc furnace, the electric arc furnace is filled with a buffer gas and an arc is started to obtain a mixture of nano-aluminum nitride and aluminum; and

[0040] The mixture is calcined under a nitrogen atmosphere to obtain high-purity nano-aluminum nitride particles.

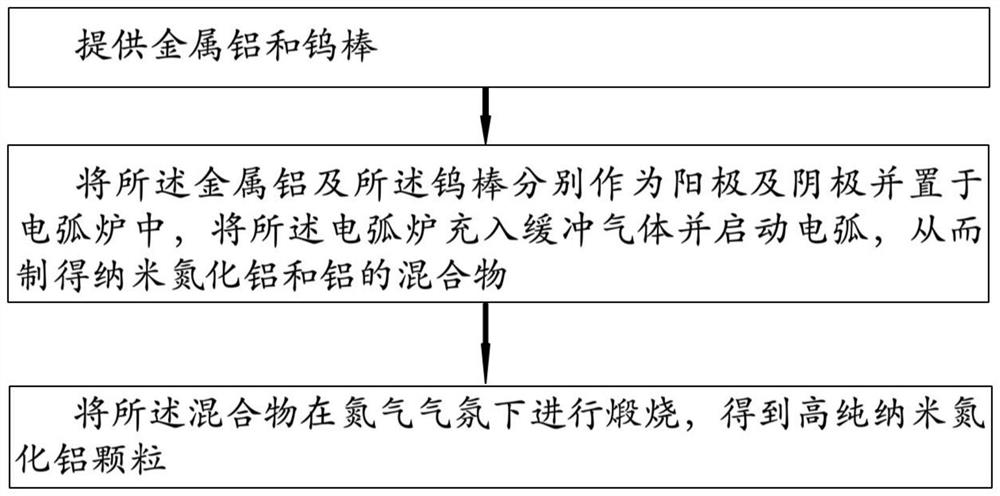

[0041] Such as figure 2 As show...

Embodiment 1

[0060] A method for preparing high-purity nano-aluminum nitride provided in Example 1 may include the following steps.

[0061] Pretreatment to remove surface oxides and impurities: use tungsten rods as cathodes, use block-shaped aluminum with a metal purity of ≥99% as anodes, and place tungsten rods and block-shaped aluminum in an electric arc furnace, where the diameter of the tungsten rods is 10mm , the distance between the block aluminum metal and the tungsten rod in the electric arc furnace is 3mm, vacuumize, fill with 10kPa hydrogen, set the discharge current to 50A, start the arc, and at the same time, turn on the vacuum pump and process for 2min. Among them, at the same time as the arc discharge, the vacuum pump of the electric arc furnace is turned on to control the flow rate of hydrogen, so that the oxides or impurities on the surface of the block refractory metal and hydrogen undergo redox reactions, and the flue gas generated during the reaction process can be The ...

Embodiment 2

[0069] A method for preparing high-purity nano-aluminum nitride provided in Example 2 may include the following steps.

[0070] Pretreatment to remove surface oxides and impurities: use tungsten rods as cathodes, use block-shaped aluminum with a metal purity of ≥99% as anodes, and place tungsten rods and block-shaped aluminum in an electric arc furnace, where the diameter of the tungsten rods is 10mm , the distance between the block aluminum metal and the tungsten rod in the electric arc furnace is 6mm, vacuumize, fill with 10kPa hydrogen, set the discharge current to 50A, start the arc, and at the same time, turn on the vacuum pump and process for 2min. Among them, at the same time as the arc discharge, the vacuum pump of the electric arc furnace is turned on to control the flow rate of hydrogen, so that the oxides or impurities on the surface of the block refractory metal and hydrogen undergo redox reactions, and the flue gas generated during the reaction process can be The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com