High heating rate controllable thermal balance

A technology of heating rate and thermal balance, applied in temperature control, non-electric variable control, control/regulation system, etc., can solve the problems of high energy consumption and low heating rate, and achieve high heating rate, wide range, and adjustable reaction atmosphere control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

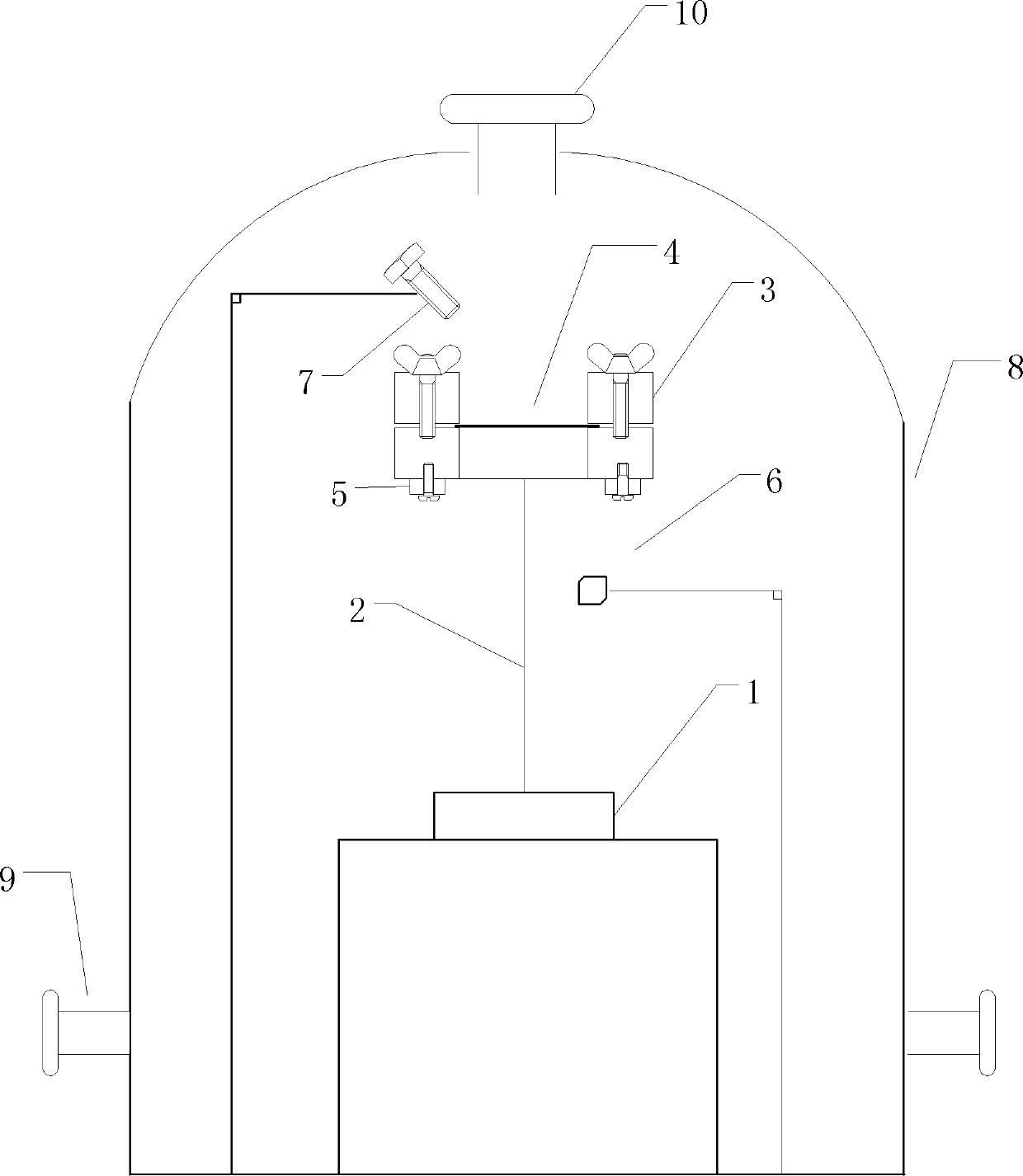

[0021] This device adopts the method of current heating, and the controlled current passes through the double-layer metal wire mesh to generate the heat required for heating. A high-sensitivity microbalance 1 constitutes the frame of the device. The high-sensitivity differential balance 1 has a balancer 2, and metal electrodes 3 are arranged at both ends of the balancer 2. During operation, the double-layer metal wire mesh 4 is clamped on the metal electrode 3, and the double-layer metal wire mesh in this embodiment is selected as a stainless steel wire mesh with an aperture of 200 mesh. The wireless receiving device 5 is connected with the metal electrode 3, and heats the double-layer metal wire mesh 4 and the material clamped between the wire mesh by receiving the electric energy transmitted by the wireless power supply device 6.

[0022] The temperature signal measured by the high-sensitivity temperature measuring device 7 is transformed into an electrical signal through a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com