Refractory metal nano nitride and preparation method thereof

A technology of refractory metal and nitride, which is applied in the field of refractory metal nano-nitride and its preparation, and can solve the problems of complex preparation process of refractory metal nano-nitride and great impact on the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

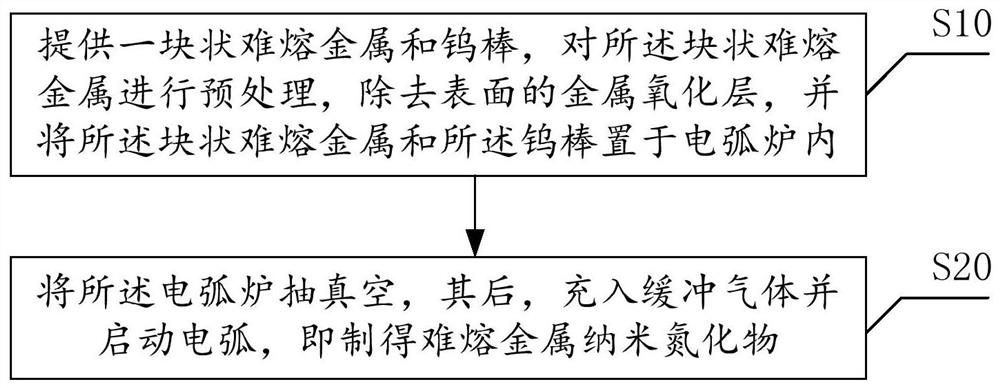

[0039] Based on the technical problems of complex preparation process of existing refractory metal nano-nitrides and relatively large environmental pollution, the present invention provides a preparation method of refractory metal nano-nitrides, such as figure 1 shown, which includes the steps:

[0040] S10. Provide a block of refractory metal and a tungsten rod, pretreat the block of refractory metal, remove the metal oxide layer on the surface, and place the block of refractory metal and the tungsten rod in an electric arc furnace Inside;

[0041] S20. Vacuum the electric arc furnace, and then fill the buffer gas and start the arc, so as to prepare the refractory metal nano-nitride.

[0042] In this embodiment, a direct current arc method is used to prepare refractory metal nano-nitrides, wherein a tungsten rod placed in an electric arc furnace is used as a cathode, and a block refractory metal is used as an anode, and the tungsten rod and the block refractory The molten m...

Embodiment 1

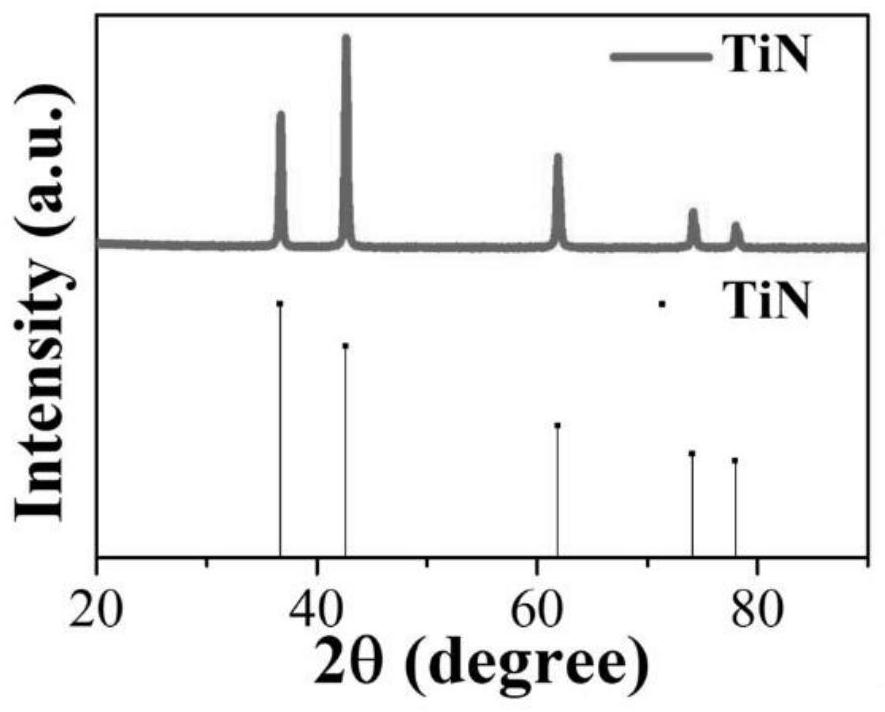

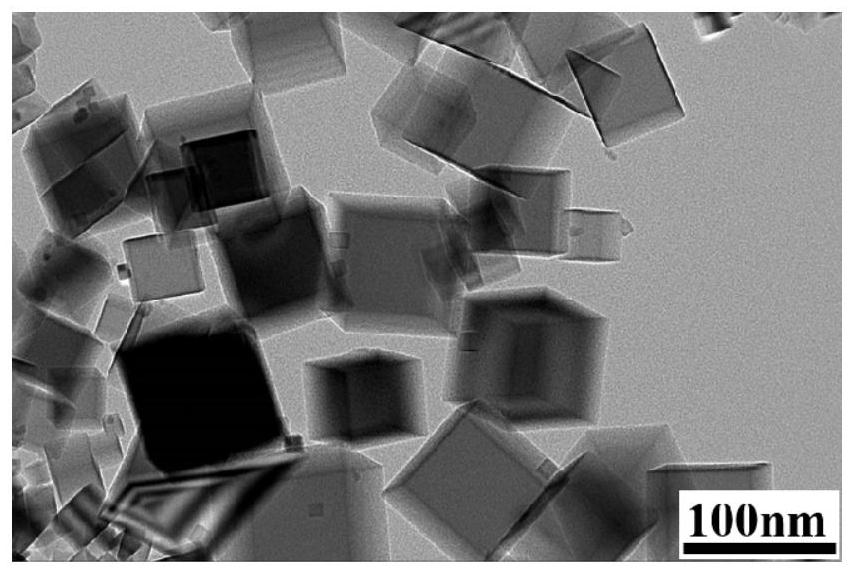

[0054] Pretreatment to remove surface oxides and impurities: use tungsten rods as cathodes, use bulk titanium with a metal purity ≥ 99.95% as anodes, place tungsten rods and block titanium in an electric arc furnace, and the diameter of the tungsten rods is 10mm , the distance between the two electrodes in the electric arc furnace is 4mm, vacuumize, fill with 20kPa of hydrogen, set the current to 80A, start the arc, and at the same time, turn on the vacuum pump and process for 4min.

[0055] Preparation of nano-titanium nitride by DC arc method: after the arc furnace is cooled, the arc furnace is evacuated to a vacuum of 3Pa, filled with nitrogen gas of 60kPa, the DC arc discharge current is set to 150A, and the discharge time is set to 30min, start After the electric arc and the reaction are completed, the deposits on the inner wall of the reaction chamber are collected to obtain titanium nitride nanoparticles.

Embodiment 2

[0057] Pretreatment to remove surface oxides and impurities: use tungsten rods as cathodes, use block-shaped zirconium with a metal purity of ≥99.95% as anodes, and place tungsten rods and block zirconium in an electric arc furnace, wherein the diameter of the tungsten rods is 20mm , the distance between the two electrodes in the electric arc furnace is 6mm, vacuumize, fill with 30kPa hydrogen, set the current to 70A, start the arc, and at the same time, turn on the vacuum pump and process for 5min.

[0058] Prepare nano-zirconium nitride by direct current arc method: After the electric arc furnace is cooled, the electric arc furnace is evacuated to a vacuum of 3Pa, and the mixed gas of nitrogen and hydrogen is filled at 60kPa, and the volume ratio of nitrogen and hydrogen is 1:1. The arc discharge current was set to 200A, the discharge time was set to 10min, and the arc was started. After the reaction was completed, the sediment on the inner wall of the reaction chamber was co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com