On-line detection device and method of mineral flotation froth flow velocity on the basis of three-dimensional visual information

A three-dimensional vision, mineral flotation technology, applied in image data processing, instruments, calculations, etc., can only measure the moving speed of foam pixels on a two-dimensional image plane, but cannot measure the speed of foam sedimentation, and the flowmeter is difficult to non-contact type. measurement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0093] The patent will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

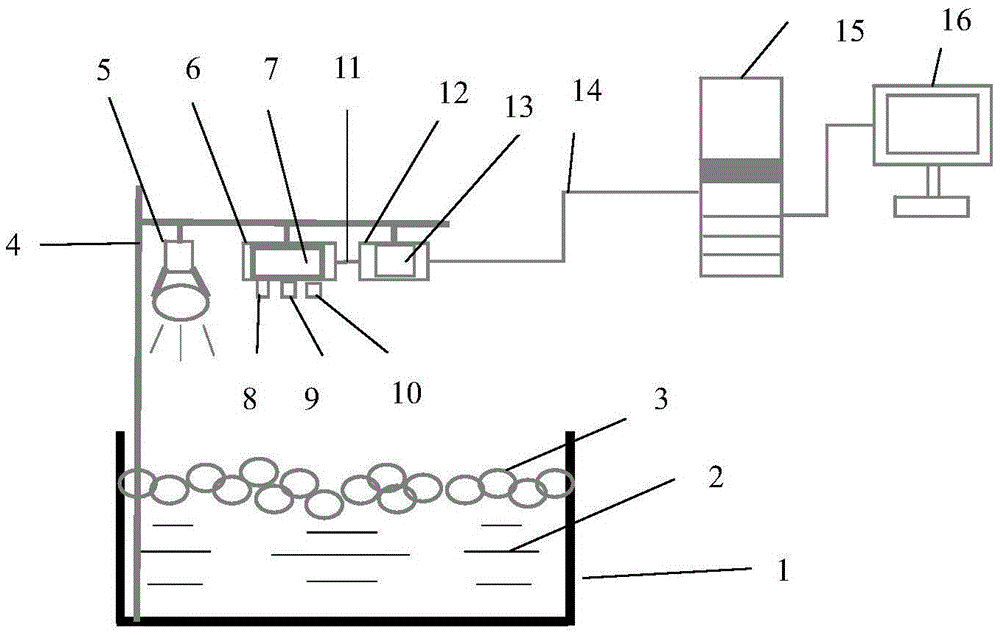

[0094] The engineering schematic diagram of the foam flow velocity on-line detection device based on three-dimensional visual information of the present invention is as follows figure 1 As shown, the project of the whole set of devices includes: flotation cell 1, pulp layer 2, foam layer 3, mounting bracket 4, high-frequency light source 5, three-dimensional foam image acquisition device protective cover 6, three-dimensional image acquisition device 7, infrared emitter 8 , color camera 9, infrared receiver 10, USB bus 11, image processing core board protective cover 12, image processing core board 13, Ethernet twisted pair 14, remote industrial computer 15, display 16.

[0095] The flotation cell 1 is a container for complex physical and chemical reactions between minerals and flotation reagents. After the reaction, a pulp layer 2 and a foam lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com