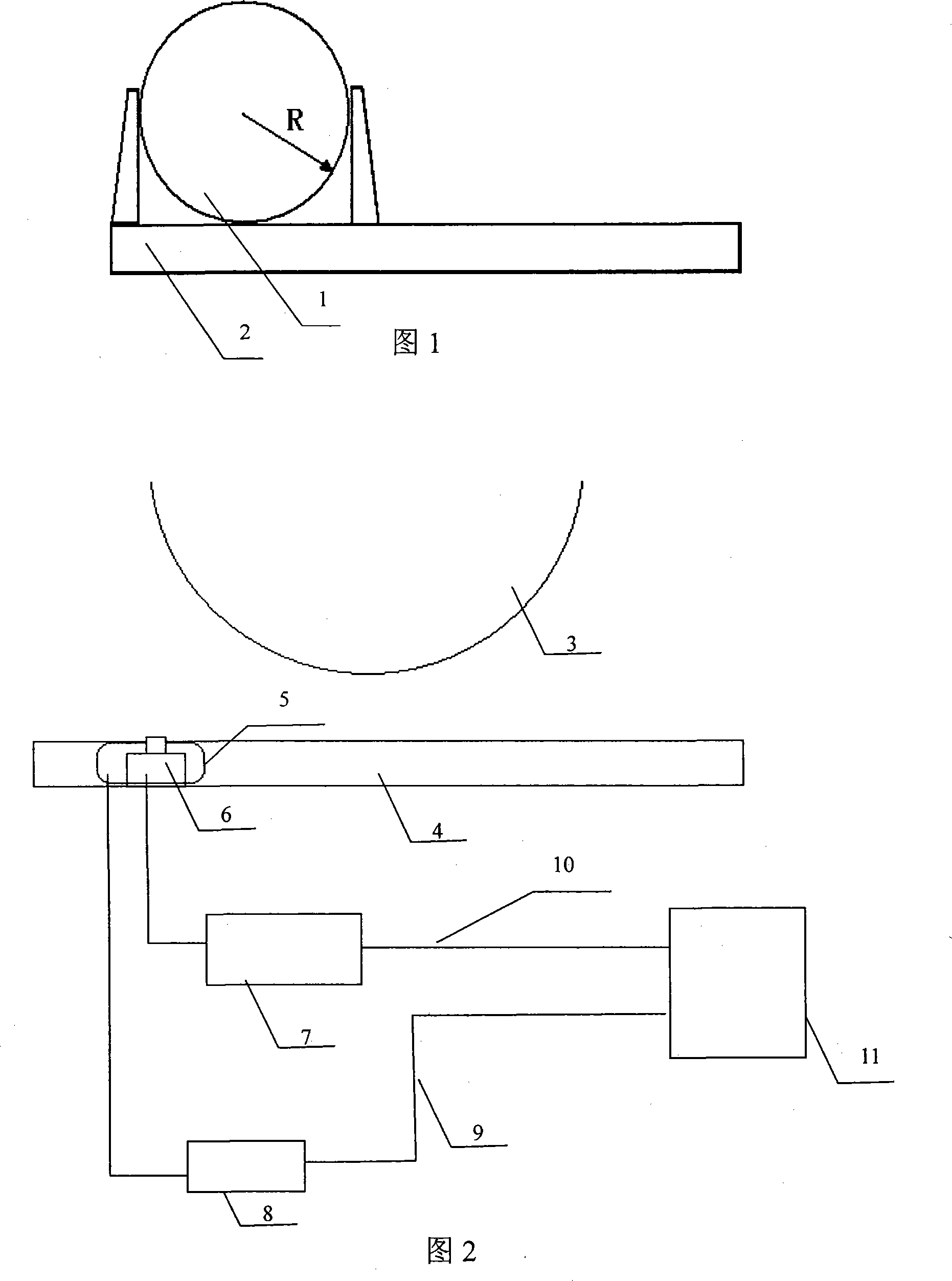

Device for non-contact measuring curvature radius with laser displacement sensor

A non-contact measurement and laser displacement technology, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems of limitation, non-complete spherical curved surfaces cannot be measured, etc., and achieve the effect of simple structure and non-contact measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

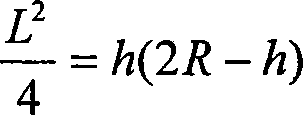

Embodiment Construction

[0011] The present invention is implemented according to the structure shown in Fig. 2, wherein the workpiece 3 to be tested can choose a workpiece with a larger curvature radius, and the grating ruler is the SGC-K2S type grating ruler produced by Changchun Optical Machine Digital Display Technology Co., Ltd., and the grating data The acquisition card 8 adopts the SGC-PC3.1 data acquisition card produced by Changchun Guangji Digital Display Technology Co., Ltd., and transmits the data to the Legend Kaitian 4600 computer 11 through the first data transmission line 9 . The laser displacement sensor 6 adopts the LK-501 laser displacement sensor produced by Keyence Corporation of Japan. The analog signal output by the laser displacement sensor is processed by the LK-2501 laser displacement sensor processor 7 matched with the laser displacement sensor. And the data is sent to the Legend Kaitian 4600 computer 11 through the second data transmission line 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com