Mirror object measuring device and method based on binocular vision

A technology of binocular vision and measuring device, which is applied in the field of contour three-dimensional reconstruction, can solve the problems that the image acquisition system is difficult to capture reflected light, relies on normal information, and is difficult to achieve, and achieves the effects of simple system structure, high measurement accuracy and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] A preferred example of the present invention is described in detail as follows in conjunction with accompanying drawing:

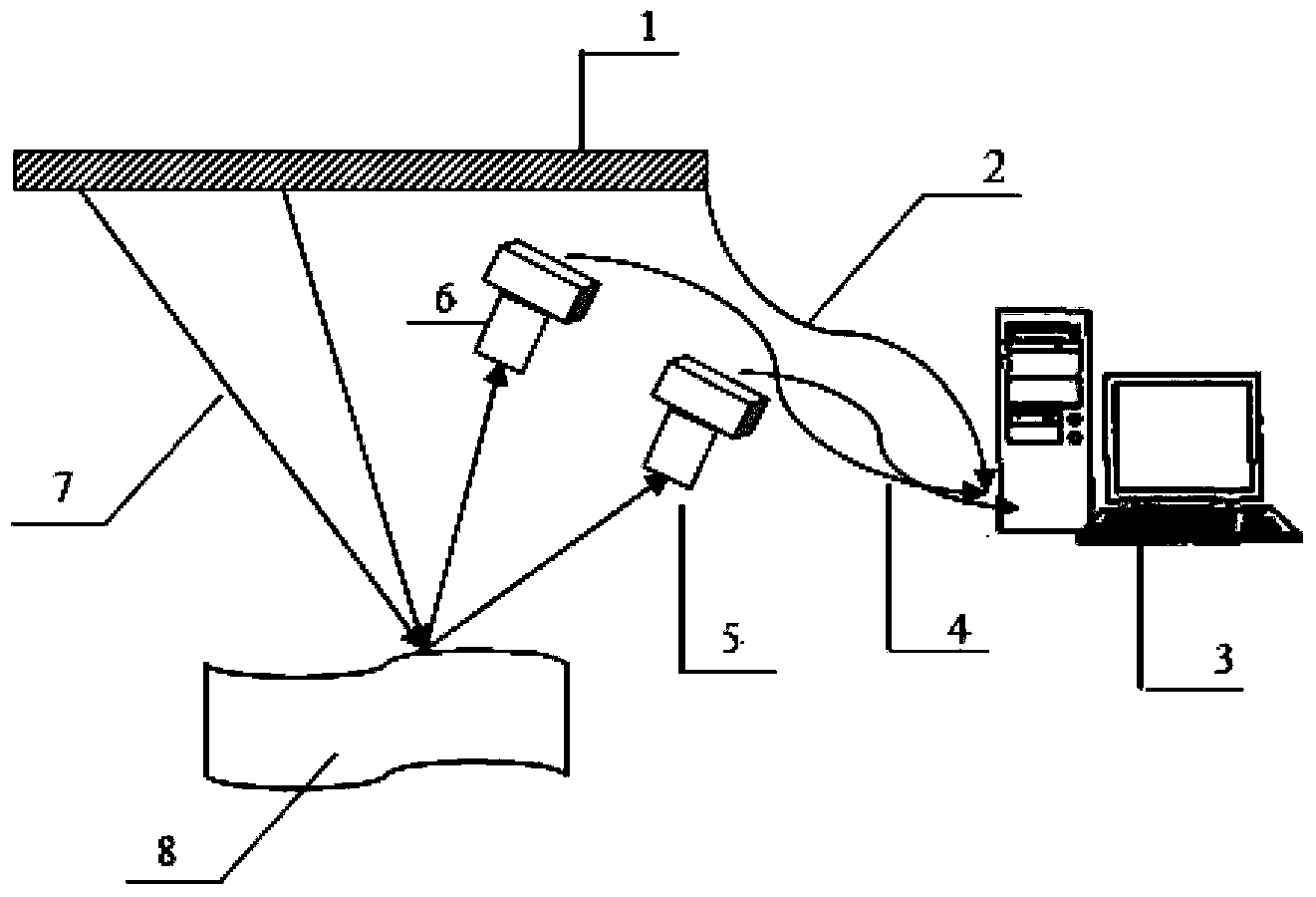

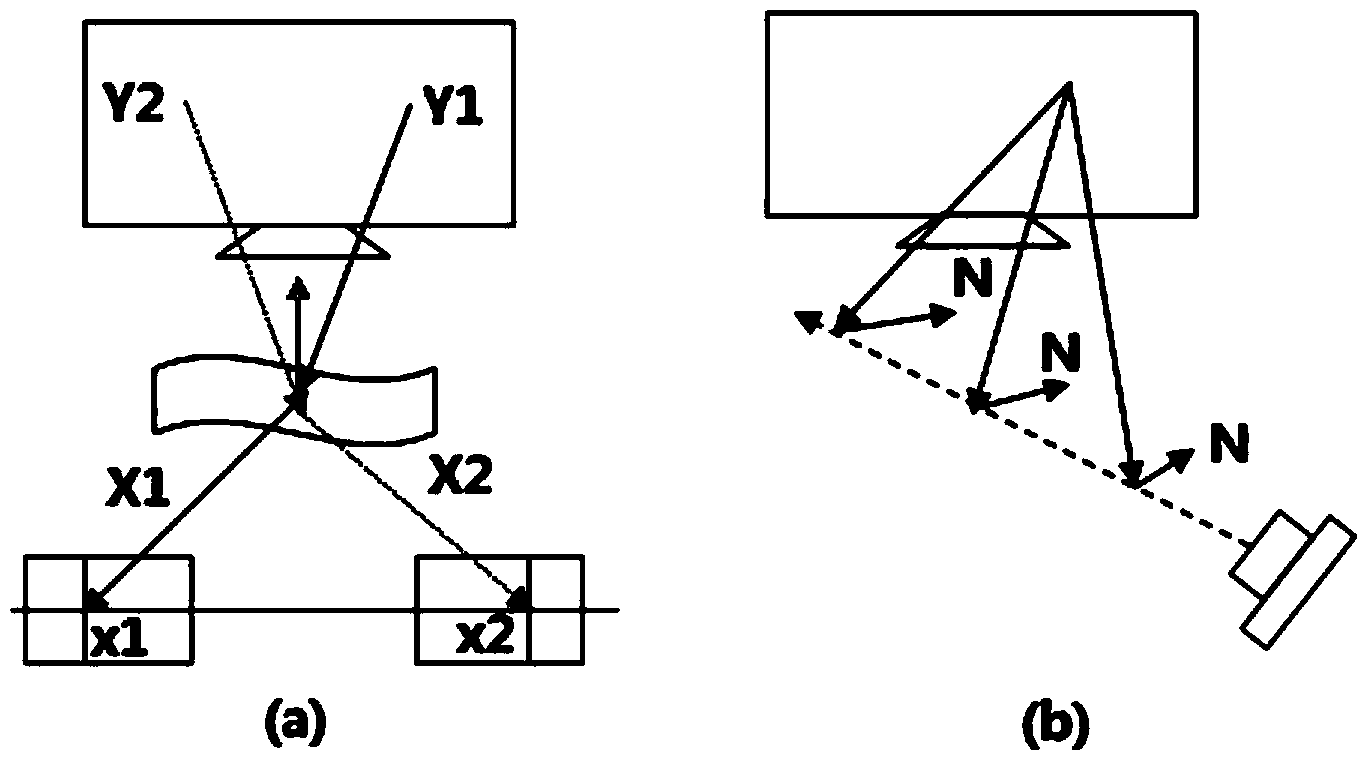

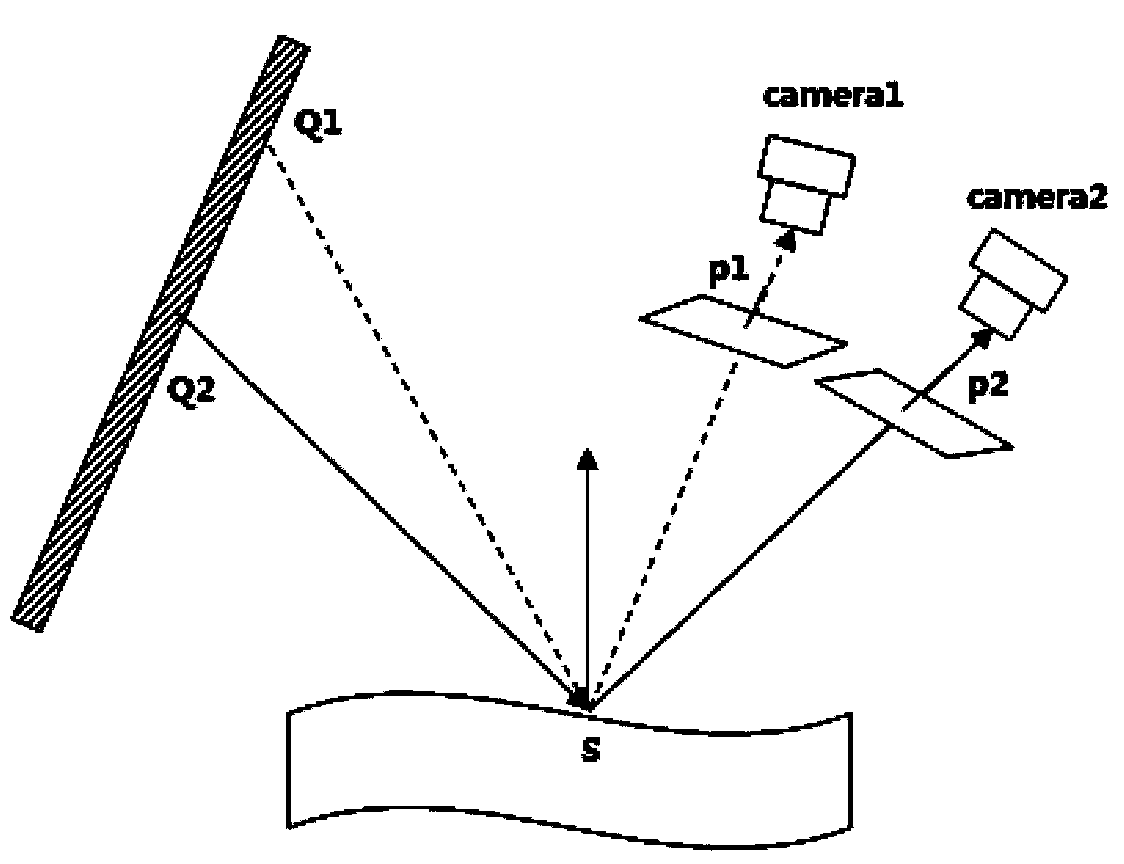

[0040] Such as figure 1 As shown, a mirror object measuring device based on binocular vision is composed of an LCD liquid crystal display 1, two industrial cameras, and a computer 3; the LCD liquid crystal display 1 is horizontally installed on the frame of the measuring device of the present invention and placed at 200mm above the measured mirror object, connected to the computer 3 through a cable, controlled by the computer 3 to generate sinusoidal fringe patterns, and project these fringe patterns on the surface of the object 8 to be measured; the industrial camera An 8mm fixed-focus lens is used, installed on one side of the LCD liquid crystal display at an angle of 65 degrees to the horizontal direction, and is symmetrical to the measured object 8, so that the distance between the lens and the surface of the measured object is 300mm, and the bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com