Accurate measurement apparatus and method for workpiece surface appearance

A workpiece surface, precision measurement technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of limited measurement range, slow measurement speed, inability to overcome the wavelength drift of light source, etc., and achieve the effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

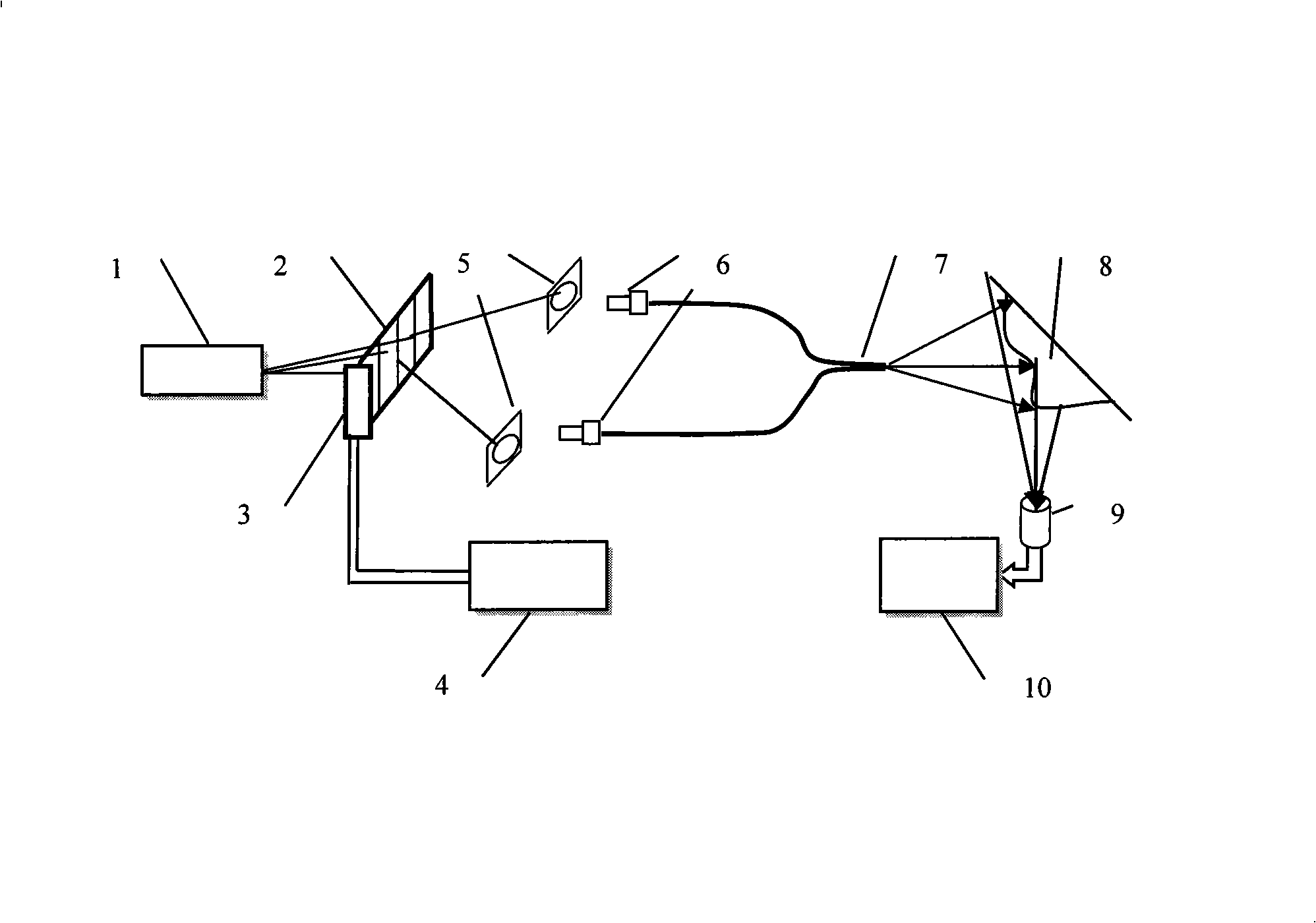

[0030] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0031] In conjunction with the accompanying drawings, the composition of the workpiece surface topography precision measuring device of the present invention includes a laser 1, a grating 2, a piezoelectric ceramic 3, a signal generator 4, a focusing lens 5, an optical fiber connector 6, an optical fiber 7, a CCD detector 9 and The computer 10, the laser 1 is located in front of the grating 2, the piezoelectric ceramic 3 is installed on the side of the grating 2, the signal generator 4 is connected to the piezoelectric ceramic 3 through a wire, and the two focusing lenses 5 are located behind the grating 2, and the emitted light of the laser passes through the rear of the grating Generate multi-level diffracted light, and couple its ±1st-order diffraction spot into two optical fibers 7 through a focusing lens. The output end of the optical fiber 7 forms two coheren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com