A photoelastic model and its manufacturing method

A production method and photoelastic technology, applied in the field of experimental mechanics research, can solve the problem that the dimensional accuracy and internal performance of the photoelastic model cannot meet the requirements of the quantitative photoelastic test of the aeroengine, and achieve the effect of convenient operation, improved purity, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

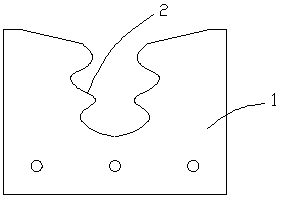

Image

Examples

Embodiment 1

[0052] A method for making a tenon-groove photoelastic model of an aeroengine turbine working blade, comprising the following steps:

[0053] S1 blank production: install the photoelastic model blank mold on the lifting platform of the vacuum casting machine, adjust the height of the lifting platform until it is convenient to watch the inlet and outlet of the photoelastic model blank mold through the observation window of the model forming room Until then, the flow guiding device in the vacuum mixing chamber of the vacuum casting machine is connected directly above the blank mold of the photoelastic model.

[0054] 128 epoxy resins, maleic anhydride are weighed 8kg by the mass ratio of 100:35, mix uniformly in the vacuum stirring control chamber, the model molding chamber is evacuated, the curing mold chamber is heated, when the curing mold chamber When the temperature is maintained at 60°C, the mixed solution of 128 epoxy resin and maleic anhydride flows to the feed port of t...

Embodiment 2

[0064] The difference between this embodiment and embodiment 1 is that the mass ratio of 128 epoxy resin to maleic anhydride is 100:30.

Embodiment 3

[0066] The difference between this embodiment and embodiment 1 is that the mass ratio of 128 epoxy resin to maleic anhydride is 100:33.

[0067] According to the recorded curing time and internal stress detection, the recorded results are shown in the following table:

[0068]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com