Capacitive microphone diaphragm, microphone and production method thereof

A capacitor and microphone technology, applied in non-planar diaphragm/paper cone, electrical components, diaphragm structure, etc., can solve the problems of reducing timbre, diaphragm fatigue, and high initial stress of diaphragm, and improve service life and reliability. , the effect of reducing the initial stress and reducing the degree of tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

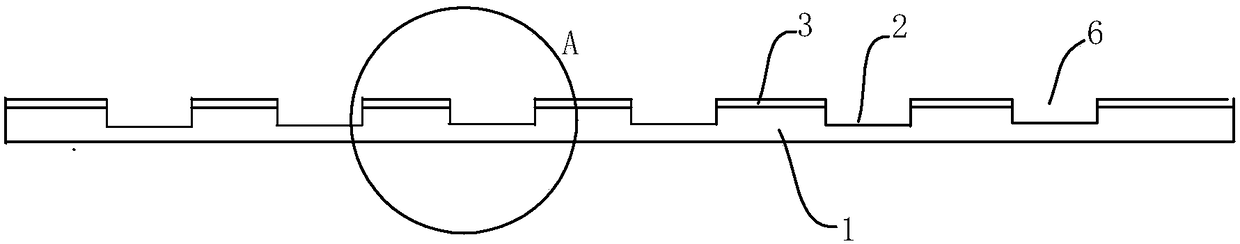

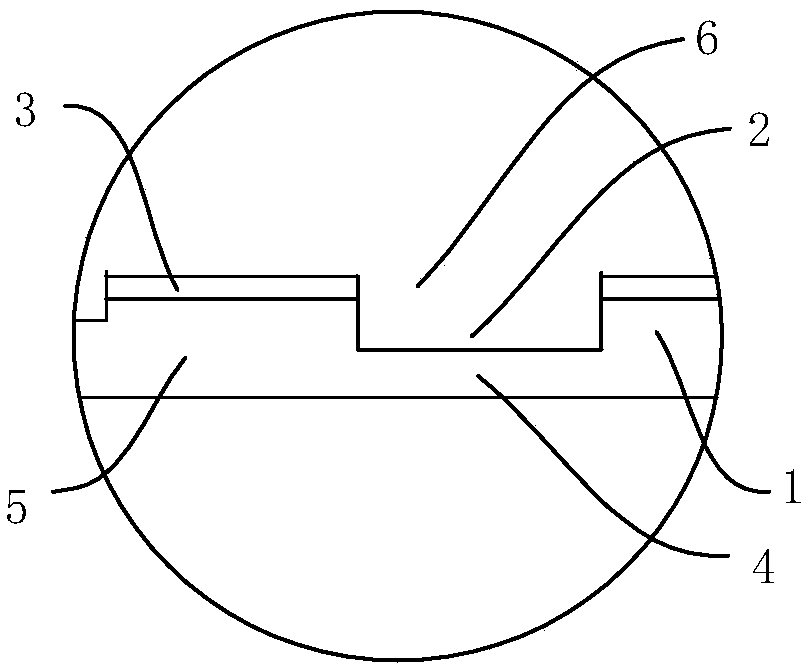

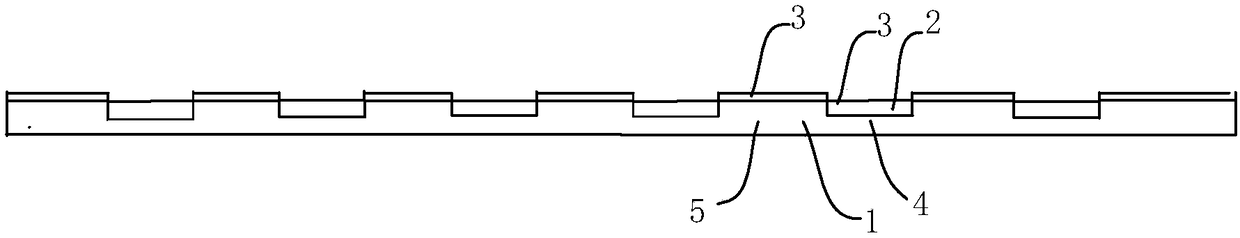

[0029] The principle of the present invention is to use laser to evenly distribute the grooves 2 on the diaphragm 1, the diaphragm 1 where the grooves 1 are located becomes thinner, and the ductility of the thinned diaphragm 1 increases, so that the central position and circumference of the diaphragm 1 The side position becomes loose at the same time, which effectively achieves the effect of slow tension and reduces the initial stress of the diaphragm, so that the entire vibration system has sufficient elasticity during energy conversion, thereby improving the tone of the diaphragm. Such as Figure 10 and Figure 11 As mentioned above, after adopting the technical solution of the present invention, the frequency response curve is obviously improved, and the timbre obtained by detection is obviously improved.

[0030] Such as Figure 1-Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com