Preparation and clamping testing device of variable-thickness hydrogel tensile sample with preset clamping rings

A technique of tensile specimen and clamping ring, which is used in the preparation of test samples, the use of stable tension/pressure to test the strength of materials, and the measurement device, etc., to prevent slippage, avoid stress concentration, and ensure accurate and reliable test results. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

[0031] A preparation and clamping test method of a hydrogel tensile sample with variable thickness and preset clamping rings, comprising the following steps:

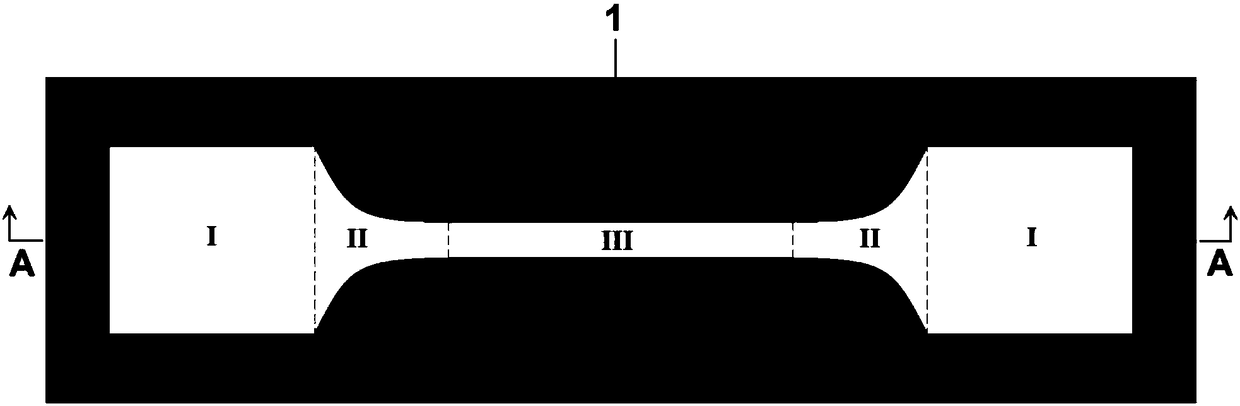

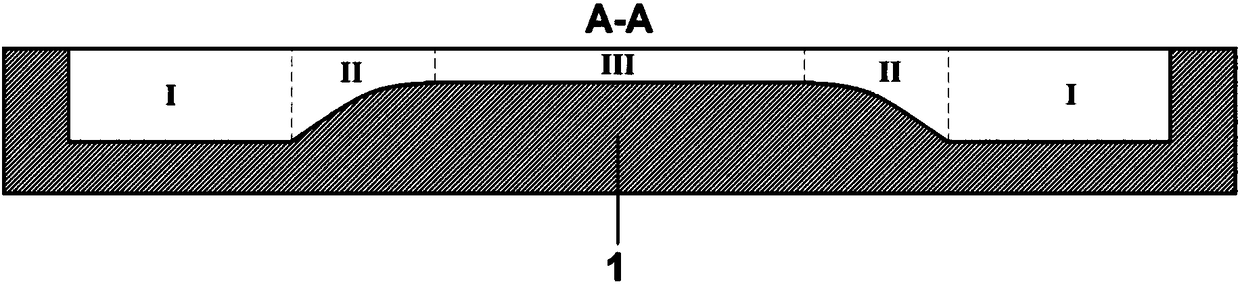

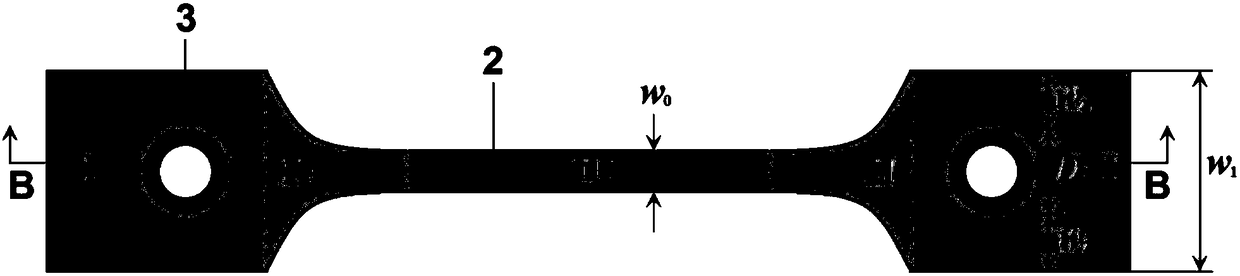

[0032] A. Referring to the corresponding national standards or common practices in the industry, first set the cross-sectional size at the gauge length section III of the hydrogel tensile sample 2, including the width w 0 , thickness t 0 (i.e. depth) and length L 0 .

[0033] B. Determine the shape and size of the clamping ring 3 according to the type of fixture of the testing machine. If a wedge-shaped self-locking clamp is used, the clamping ring 3 can be solid or hollow. In this embodiment, solid is used, and its outer diameter D is taken as 2w 0 , thickness t 2 Than t 1 1mm larger. Prepared by 3D printing technology, the material is hard plastic.

[0034] C. According to w 0 , t 0 and L 0 To deter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com