Single-axle double-direction symmetric stretching experimental machine

A uniaxial, bidirectional, experimental machine technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of large size of the loaded specimen, high loading speed of the specimen, and unfavorable deformation of the micro-area of the specimen. The effect of reducing transmission error, improving transmission accuracy and reliable measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The parameters of each element in the system are: the maximum load of the test piece is 150N, the maximum movement displacement is 10mm, the load range of the force sensor is 200N, and the resolution is 1N.

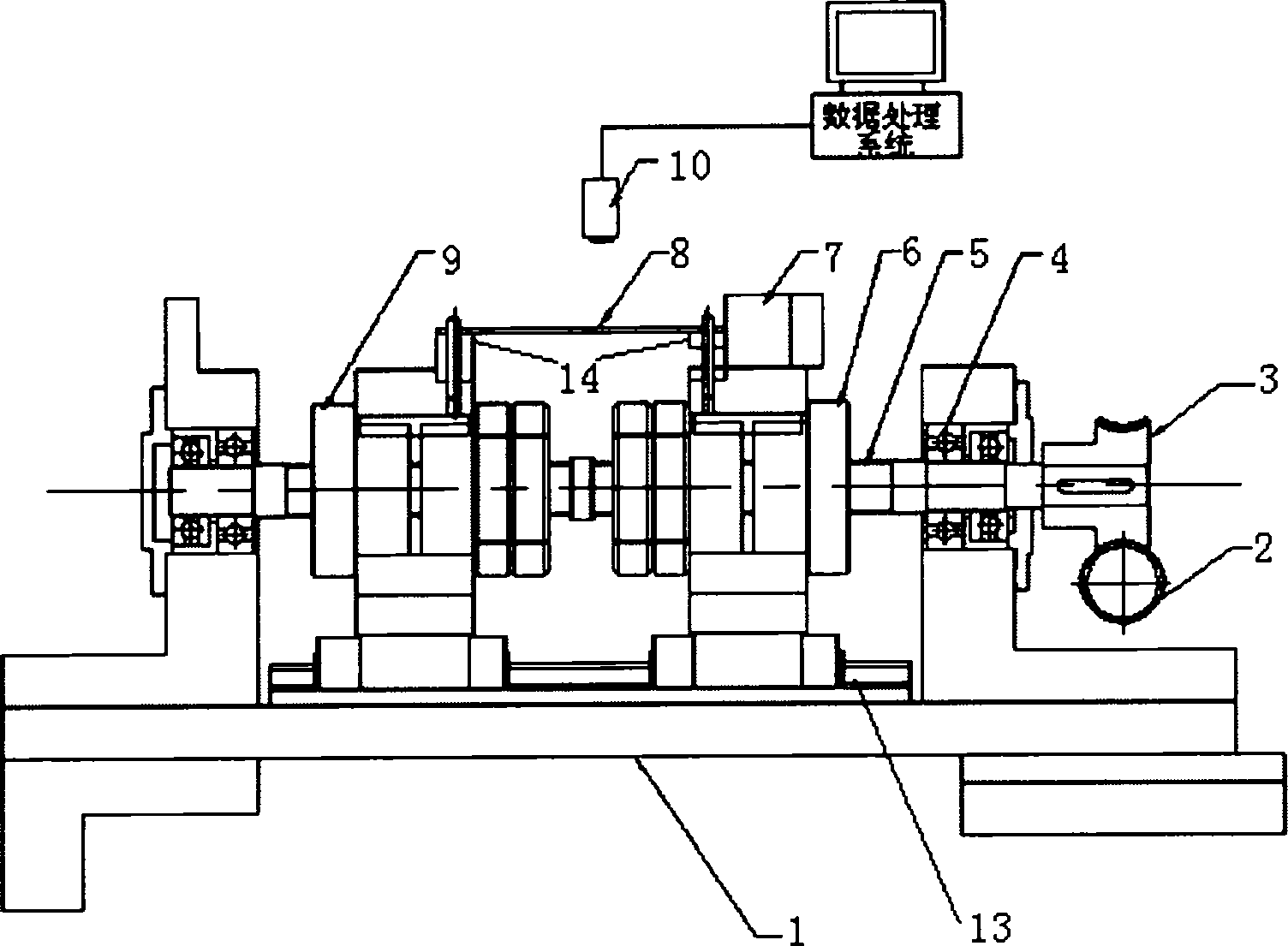

[0019] The main view of the structure diagram of the present invention is as figure 1 As shown, the whole device includes a stepper motor 11, a stepper motor controller 12, a force sensor 7, a worm gear 3, a worm 2, a ball screw 5, a left nut 9, a right nut 6, a linear guide 13, a bearing 4, and a frame 1. Coupling 15, specimen clamping device 14.

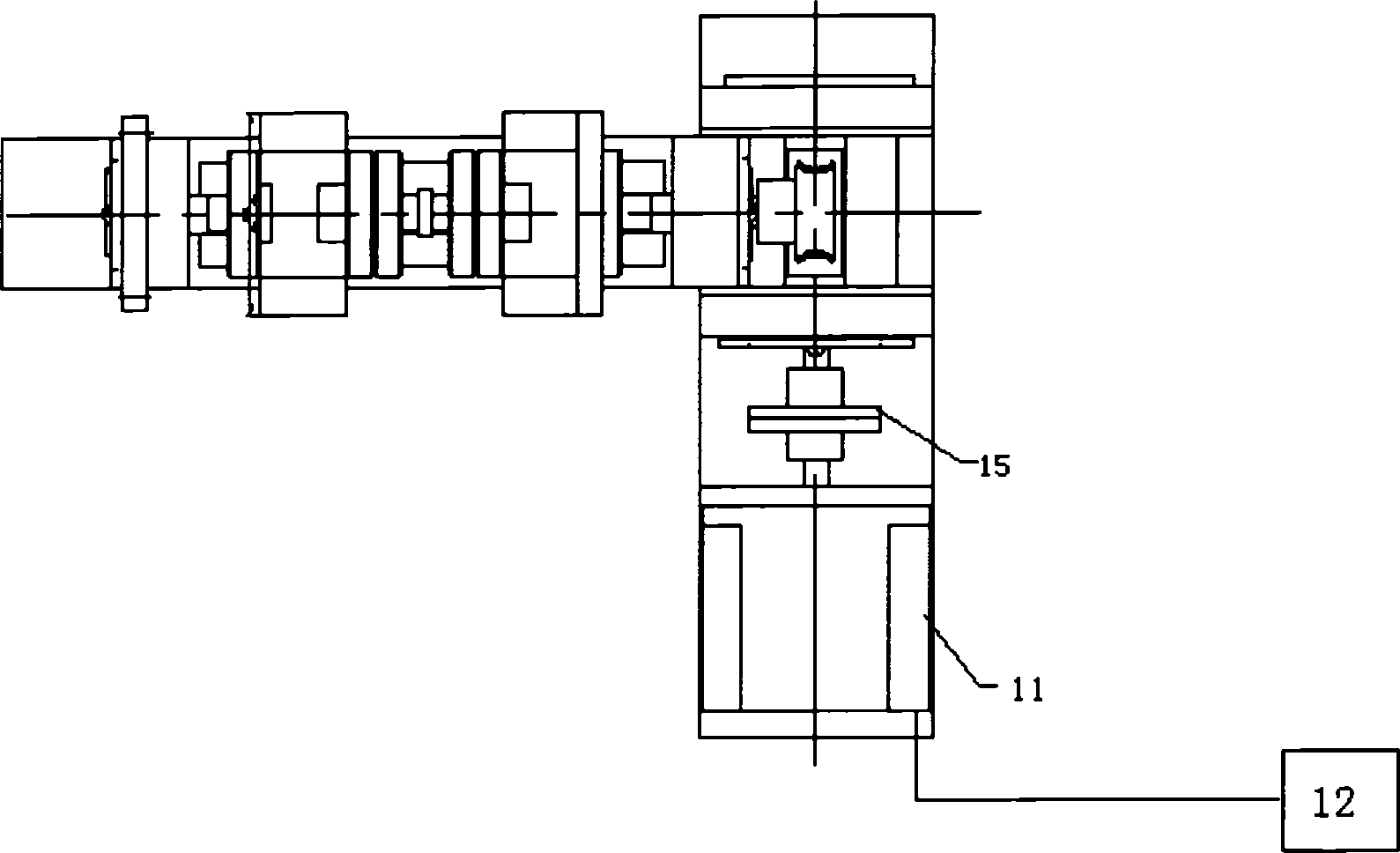

[0020] figure 2 It is a top view of the structure of the present invention. Among them, 11-stepping motor; 12-stepping motor controller; 15-coupling.

[0021] The connection relationship of the above components is: the stepper motor controller 12 controls the stepper motor 11; the stepper motor 11 is connected to the worm 3 through the coupling 15, and the worm and the matched worm wheel 2 realize movement transmission a...

Embodiment 2

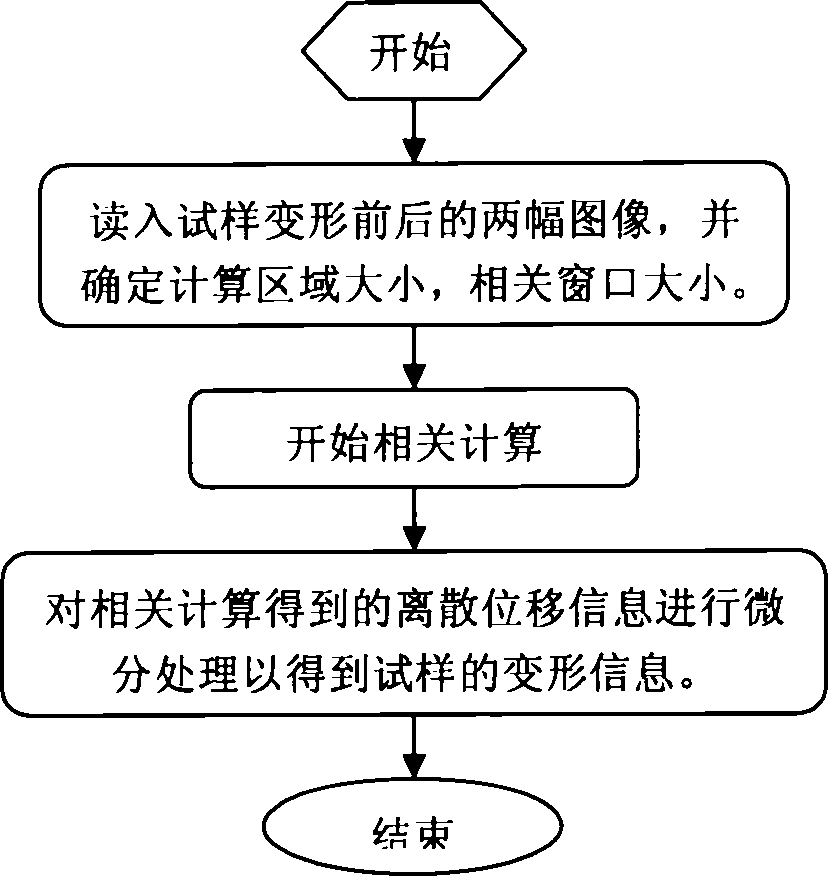

[0028] The parameters of each element in the system are: the maximum load of the test piece is 150N, the maximum movement displacement is 10mm, the load range of the force sensor is 200N, and the resolution is 1N. The imaging part of the non-contact optical measurement system consists of an imaging lens and a CCD. The appropriate magnification can be selected according to the size of the sample, and the middle part of the sample can be accurately imaged and stored in the data processing system connected with the CCD. Related procedures to calculate the deformation information of the specimen.

[0029] The structure of the present invention is as figure 1 As shown, the whole device includes a stepper motor 11, a stepper motor controller 12, a force sensor 7, a worm gear 3, a worm 2, a ball screw 5, a left nut 9, a right nut 6, a linear guide 13, a bearing 4, and a frame 1. Coupling 15, specimen clamping device 14. The non-contact optical measurement part consists of a CCD 10 and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com