Strain calibration device applied to high-temperature and high-pressure underwater

A technology of high temperature and high pressure water and calibration device, which is applied in the field of strain calibration, can solve problems such as the inability to realize strain calibration, and achieve the effect of improving accuracy and wide application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

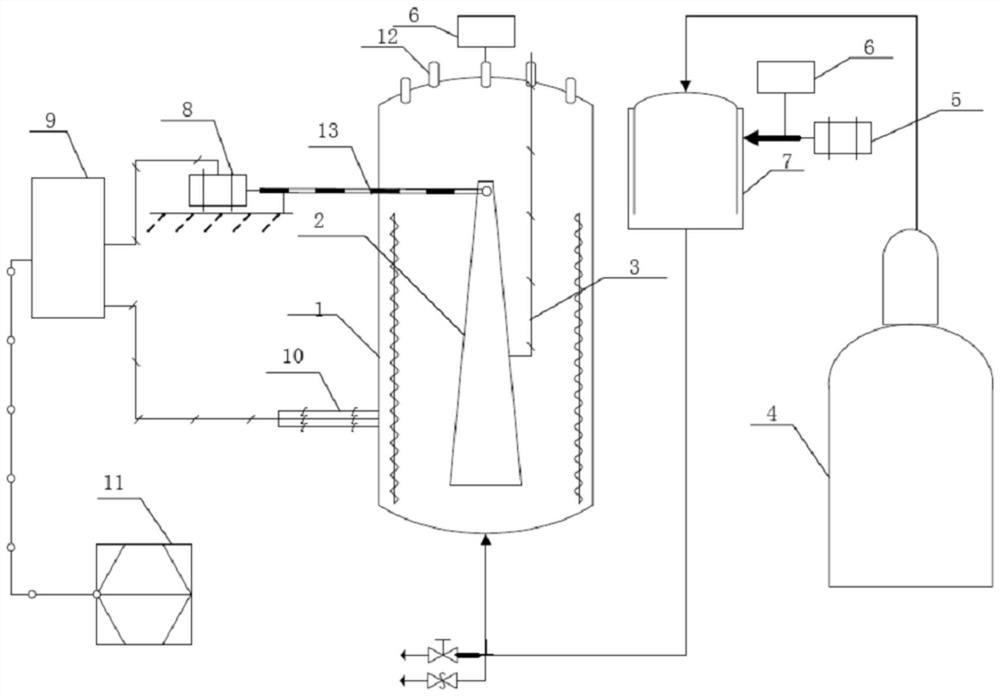

[0055] Compared with the existing strain calibration devices, which are mainly aimed at high-temperature environments, the characteristics of high-pressure underwater strain are not considered, that is, the existing strain calibration devices cannot be applied to high-temperature and high-pressure underwater strain calibration. Therefore, this embodiment provides a strain calibration device applied to high temperature and high pressure underwater, such as figure 1 As shown, the device of this embodiment includes an autoclave 1, a calibration beam 2, a pressure system, a displacement system and a temperature system.

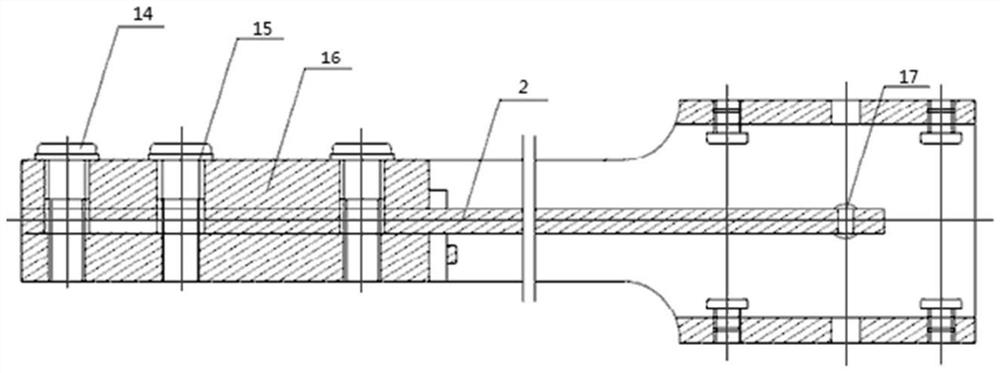

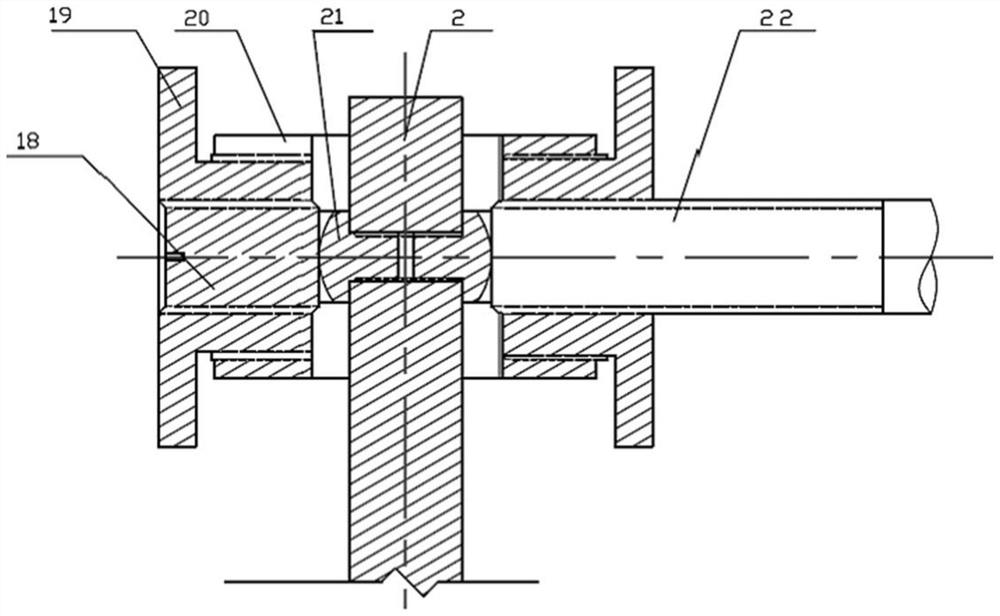

[0056] Among them, the calibration beam 2 is fixedly installed inside the autoclave 1 through a fixing device, and the measured sensor (measured strain gauge) is set on the calibration beam 2; the pressure system is used to provide a high-pressure environment for the inside of the autoclave 1; the displacement system adopts automatic displacement The loading unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com